Aging treatment, also known as precipitation hardening, is a key step in modern heat treatment technology. This process follows solution treatment and involves heating alloys at a controlled temperature to allow the formation of fine precipitates, which strengthen the metal.

Author Archives: ZYLAB Solution

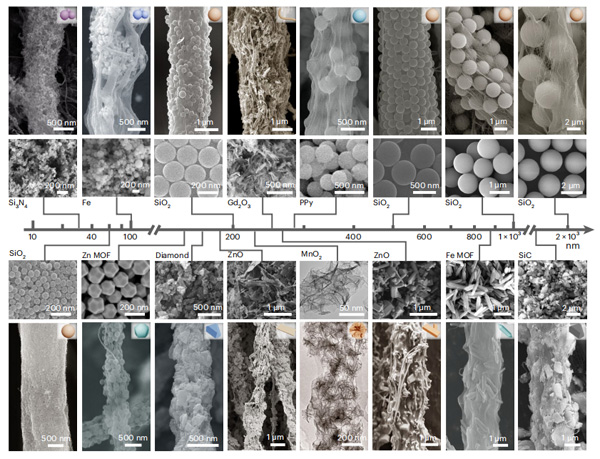

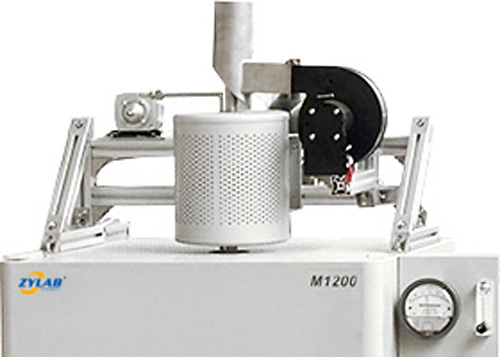

This article provides a research-focused overview of powder material fibrillation, covering mechanisms, materials, processing methods, and typical applications, including laboratory-scale studies using jet milling equipment such as the Lab Scale Jet Mill.

The development of high-performance functional materials is critical for flexible electronics and next-generation energy devices. Flexible transparent conductive films (TCFs) and electrode functional layers are foundational for wearable devices, foldable displays, batteries, supercapacitors, and solar cells. Achieving uniform, defect-free coatings with precise control over composition and microstructure is challenging. Ultrasonic Atomization Chemical Vapor Deposition (CVD) provides a precise solution for laboratory-scale material research.

In the field of heat treatment, solution treatment (also known as solid solution treatment) is a critical process for improving the mechanical and corrosion-resistant properties of metals, especially stainless steels, nickel-based alloys, and aluminum alloys. The process involves heating the alloy to a high temperature to dissolve alloying elements into a solid solution, followed by rapid cooling to retain this uniform structure.

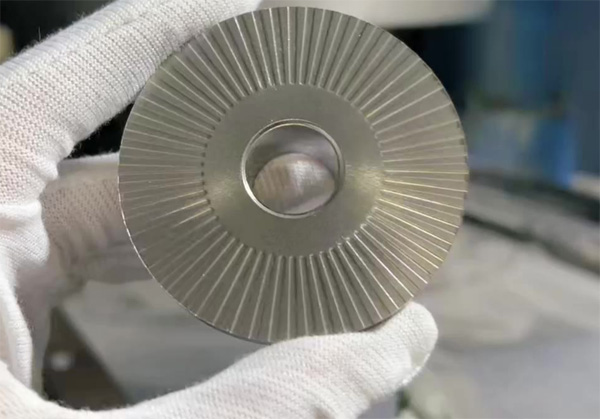

After sintering, powder metallurgy (PM) components often require post-processing treatments to achieve their final mechanical properties, dimensional accuracy, and surface quality. These additional steps are critical for ensuring that PM products meet the stringent demands of industrial and research applications in fields such as automotive, aerospace, electronics, and biomedical engineering.

Sintering is one of the most critical stages in the powder metallurgy (PM) process. It transforms the fragile, porous “green compact” formed during the shaping stage into a dense, mechanically strong metal component.

In high-temperature industrial processes such as sintering, metal melting, and ceramic firing, furnaces generate exhaust gases that may contain unburned hydrocarbons, volatile organic compounds (VOCs), or other harmful emissions. To address this issue, many modern furnaces are equipped with an afterburner system, also known as a secondary combustion chamber.

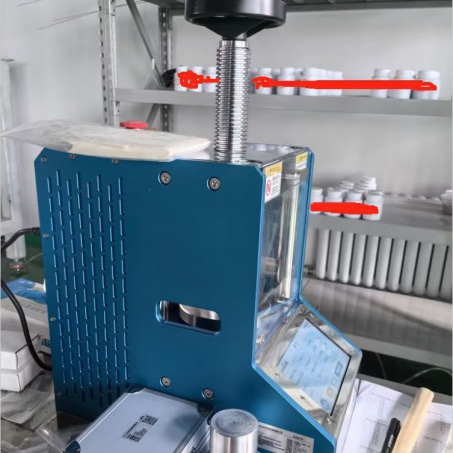

Proper hydraulic oil filling is essential to ensure the stable operation, pressing accuracy, and long service life of a powder pellet press machine. Whether you are using a 20-ton, 30-ton, or 100-ton fully automatic powder pellet press or other models, correct oil filling and maintenance are key to reliable performance and smooth operation.

Proper maintenance is essential to ensure the stable performance, long service life, and safety of a tablet press machine. Regular inspection, lubrication, and cleaning not only help prevent equipment failure but also ensure consistent tablet quality.

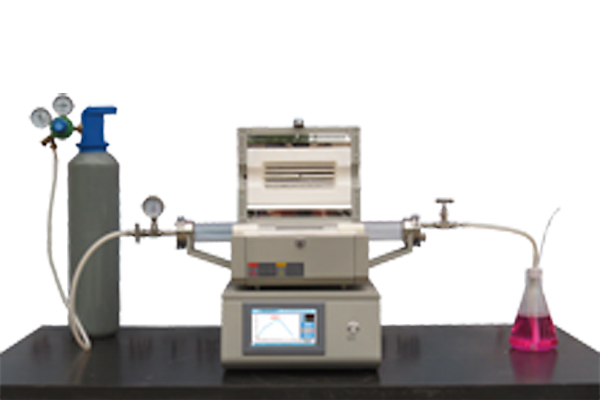

Using a mini tube furnace safely requires careful attention to pressure control, gas flow, temperature calibration, and material purity. Following these precautions will help you achieve reliable high-temperature sintering results, protect the furnace from damage, and maintain a safe laboratory environment.