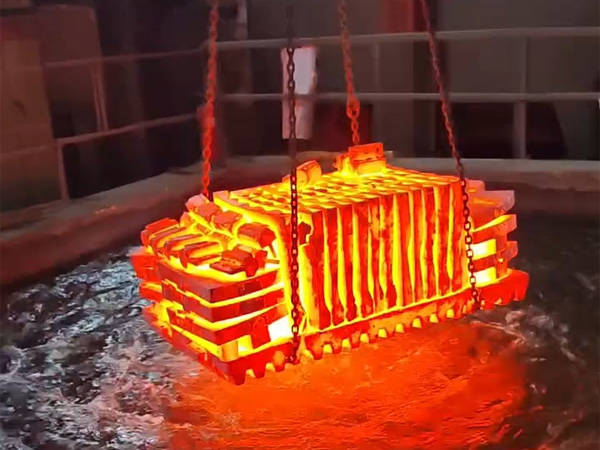

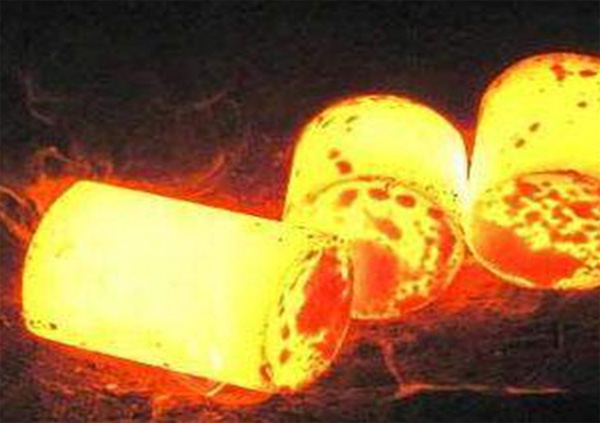

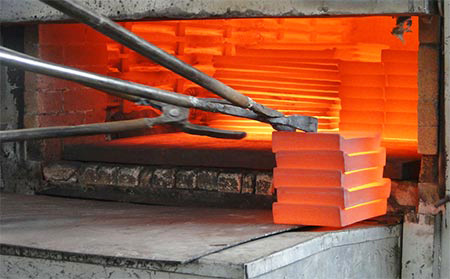

Quenching is a key heat treatment process designed to achieve extreme hardness through rapid cooling. By quickly lowering the temperature, metals and alloys transform their microstructure, locking in strength and wear resistance. In this article, we explore the principles and techniques of quenching, revealing how speed and precision create high-performance materials.

Author Archives: ZYLAB Solution

Normalizing is another essential heat treatment process used in metallurgy and materials engineering. In this article, we continue our Heat Treatment Series by explaining the definition, purpose, and unique features of normalizing, while also comparing it to annealing.

Annealing is one of the fundamental heat treatment processes widely used in metallurgy, materials science, and industrial manufacturing. In this Heat Treatment series, we explore the definition, purpose, types, and essential knowledge about annealing.

This guide provides laboratory researchers with a practical overview of grinding media materials, their properties, and recommended applications. ZYLAB offers a comprehensive range of ball mill jars and balls, making it easier to match the right media to your research needs.

ZYLAB was recently approached by a prestigious university in Malaysia with a specialized requirement for their laboratory and pilot-scale research work. The university needed 2 sets large-capacity 100L vacuum filters with enhanced corrosion resistance to ensure reliable performance during demanding experiments and material processing.

This guide explains how the most commonly used lab mills work, which powder types each is best suited for, and practical tradeoffs lab researchers should consider.

Among various laboratory heating instruments, a 1700℃ tube furnace stands out for its high-temperature capabilities, uniform heating, and versatility in catalyst synthesis. This article explores how a 1700℃ tube furnace supports high-efficiency catalyst preparation experiments, its advantages, and practical applications.

This article delves into the technical role of high-temperature tube furnaces in carbon-based composite synthesis, focusing on temperature control, atmosphere management, and material uniformity—critical parameters for researchers and engineers in advanced material science.

At ZYLAB, we take pride in delivering tailor-made solutions for sample preparation and thermal processing to some of the world’s leading companies.

A recent collaboration with ExxonMobil, a global energy and chemical leader, perfectly illustrates our expertise. For one of their advanced research projects, ExxonMobil required a 7×7mm split mold that offered exceptional precision, durability, and ease of use.

For enterprises in the precious metals industry, the adoption of a hydrogen reduction furnace represents a leap forward in both technology and sustainability. By delivering higher efficiency, superior product purity, and reduced environmental impact, this equipment has become an indispensable tool for forward-thinking companies.