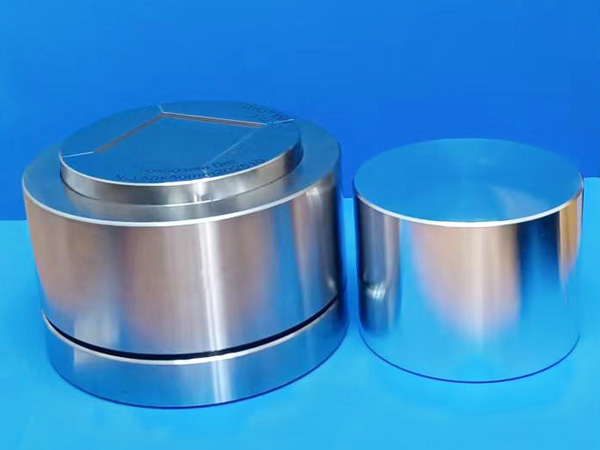

ZYLAB supplied a 50×50 mm square split pressing die set to Tallinn University for powder sample forming, improving accuracy, stability, and lab research efficiency.

Author Archives: ZYLAB Solution

ZYLAB supplied a custom ceramic settle plate with grooves for a leading U.S. insulation and sealing technology company, improving efficiency and high-temperature stability.

In the era of advanced materials and renewable energy technologies, research on metal oxide powders under high-temperature reducing conditions has become a core focus for universities, research institutes, and industrial R&D labs. To support such cutting-edge studies, ZYLAB has delivered a custom rotary hydrogen furnace to a leading Asian technical university, specifically designed for powder research.

Sintering under a reducing atmosphere (e.g., H₂, forming gas, N₂/H₂ blends) offers crucial benefits— oxide removal, improved densification, enhanced mechanical properties — for metal and ceramic powders. This article reviews the mechanism, process parameters, advantages, limitations, and application guidelines of high‑temperature reducing‑atmosphere sintering, providing a reference for researchers and industrial practitioners.

High-temperature heat treatment furnaces are essential tools in materials science, thermodynamics research, and industrial processing.

Recently, a UK client asked if we could provide a rotary furnace that can accommodate quartz tubes with an 80 mm diameter and 400 mm heating length.

In response, ZYLAB proposed our Vibrating Rotary Sintering Furnace, engineered for high-precision sintering, mixing, and thermal processing. This blog explores its features, benefits, applications, and why UK thermodynamics labs trust ZYLAB.

Hydrogen reduction is one of the most important processes in metal powder production and purification. For researchers working with copper powder, iron powder, and other high-purity metal or alloy particles, achieving a stable, uniform, and safe reducing atmosphere is essential. A swing (rocking) hydrogen atmosphere furnace provides a more efficient and homogeneous heat-treatment environment compared with fixed-bed reduction furnaces, making it widely used in laboratories, pilot lines, and materials R&D.

At leading research institutions such as the University of Cyprus, precision, reliability, and reproducibility are essential for advanced material science and nanotechnology studies. The ZYLAB Lab Ultrasonic Nebulizer is designed to meet these exact needs, providing a robust solution for applications such as aerosol-assisted chemical vapor deposition (AACVD), nanomaterials synthesis, and thin-film deposition.

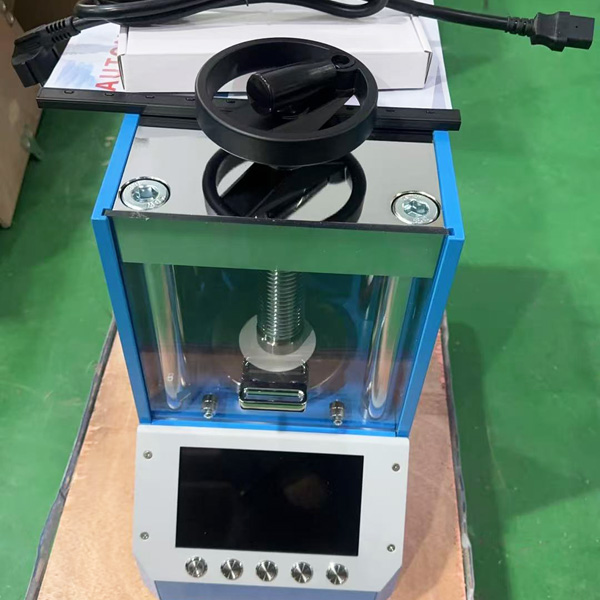

ZYLAB recently had the opportunity to support a leading European technology and innovation company by providing our 20-Ton Automatic Powder Pellet Press, designed for high-precision pellet pressing in R&D and small-scale production.

In advanced cement research, precision powder processing is essential for material development, performance evaluation, and formulation innovation. ZYLAB recently supplied a Lab Scale Jet Mill to a leading U.S. cement research company for small-batch ultra-fine grinding, enabling more accurate and consistent R&D results.

High-temperature furnaces are widely used in industries such as materials research, ceramics, metallurgy, and additive manufacturing. During operation, these furnaces often generate hazardous exhaust gases, including silanes, halides, acid/base gases, and dust particles. Effective exhaust gas treatment solutions are essential for environmental compliance, workplace safety, and furnace longevity.