High-temperature heat treatment furnaces are essential tools in materials science, thermodynamics research, and industrial processing.

Recently, a UK client asked if we could provide a rotary furnace that can accommodate quartz tubes with an 80 mm diameter and 400 mm heating length.

In response, ZYLAB proposed our Vibrating Rotary Sintering Furnace, engineered for high-precision sintering, mixing, and thermal processing. This blog explores its features, benefits, applications, and why UK thermodynamics labs trust ZYLAB.

Category Archives: Powder Processing

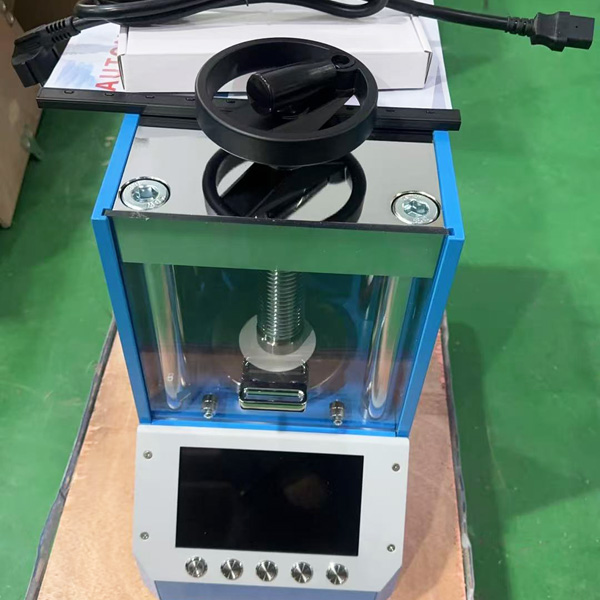

ZYLAB recently had the opportunity to support a leading European technology and innovation company by providing our 20-Ton Automatic Powder Pellet Press, designed for high-precision pellet pressing in R&D and small-scale production.

In advanced cement research, precision powder processing is essential for material development, performance evaluation, and formulation innovation. ZYLAB recently supplied a Lab Scale Jet Mill to a leading U.S. cement research company for small-batch ultra-fine grinding, enabling more accurate and consistent R&D results.

At ZYLAB, we take pride in delivering tailor-made solutions for sample preparation and thermal processing to some of the world’s leading companies.

A recent collaboration with ExxonMobil, a global energy and chemical leader, perfectly illustrates our expertise. For one of their advanced research projects, ExxonMobil required a 7×7mm split mold that offered exceptional precision, durability, and ease of use.

Lab scale jet mills have become essential in modern laboratories where high-purity, ultra-fine powders are required. Compared to traditional milling methods such as ball mills and planetary mills, they offer contamination-free milling, precise particle size control, and efficient small-batch operation.

At ZYLAB, we specialize in delivering high-precision, customized laboratory tools that meet the evolving needs of researchers around the world. Recently, we proudly supplied a 10×10 mm split-type square pellet pressing mold to the University of Groningen, one of the Netherlands’ most prestigious research institutions.

This project reflects our continued commitment to supporting world-class scientific research with reliable and user-friendly sample preparation solutions.

At ZYLAB, we take pride in supporting global partners with high-performance laboratory solutions. Recently, we successfully supplied a Compact Jet Mill to a mid-to-large-sized chemical and equipment supplier based in Matamoros, Mexico. Known for its extensive distribution of agrochemicals, lab equipment, and industrial systems, this company serves a wide range of research and production facilities across Mexico and Latin America.

Whether you’re developing battery materials, advanced ceramics, or pharmaceutical powders, contamination-free and efficient grinding is essential. Laboratory jet mills offer a powerful and compact solution for researchers seeking high-performance results on a small scale.

A sieve shaker is a laboratory instrument used for particle size analysis, separation, and classification of granular materials. It is compact, low-noise, and capable of precisely separating granular materials into 2 to 7 particle size fractions.

It involves multiple steps and techniques, including ultrafine grinding, precision grading, high homogenization, dispersion, composite coating, modification, drying, sintering, storage, packaging, and transportation, aiming to improve powder performance, enhance production efficiency, and meet specific industrial demands.

- 1

- 2