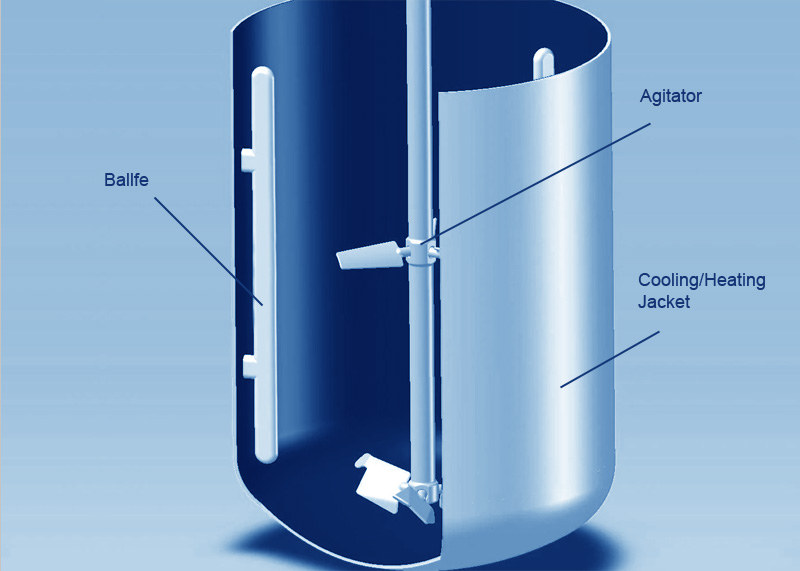

Baffles in a glass-lined reactor are fixed structures mounted on the inner wall of the reactor to improve the internal fluid dynamics, enhancing stirring and mixing efficiency.

Author Archives: ZYLAB Solution

It involves multiple steps and techniques, including ultrafine grinding, precision grading, high homogenization, dispersion, composite coating, modification, drying, sintering, storage, packaging, and transportation, aiming to improve powder performance, enhance production efficiency, and meet specific industrial demands.

In the realm of modern manufacturing, Powder Metallurgy (PM) stands out as an innovative and efficient production method, gaining popularity across various industries. By utilizing metal powders or a mixture of metal and non-metal powders, this technique involves pressing and sintering to create high-precision, high-performance metal components.

When using a 1700°C high-temperature sintering furnace, it is essential to follow specific precautions to ensure safe and efficient operation.

The vertical planetary ball mill is primarily used for primary crushing (0.5-3mm), fine grinding (5-75µm), precision grinding (0.1µm), mixing, sample preparation, nano-material grinding, dispersion, alloying, synthesis, the development of new products, and small-scale production of high-tech materials.

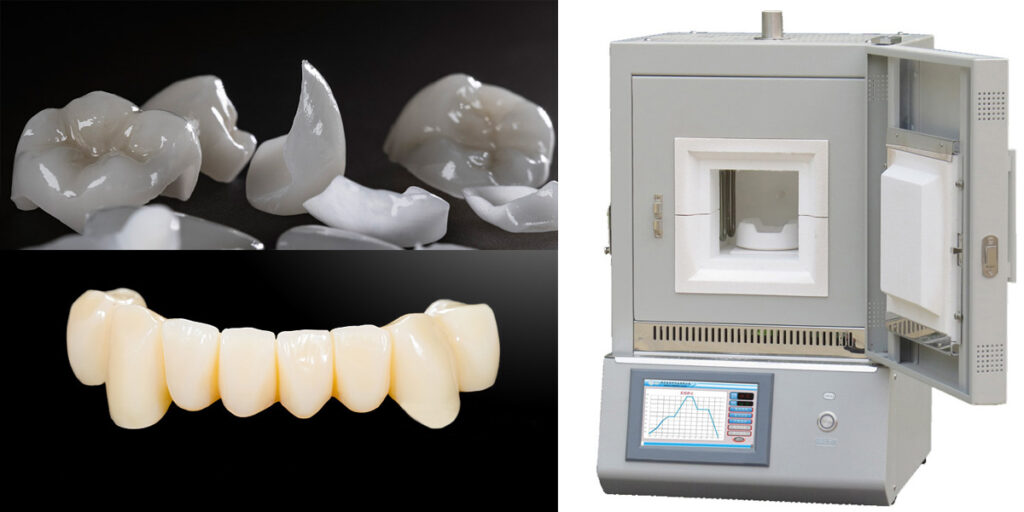

Zirconia dental prosthesis sintering involves the high-temperature sintering of zirconia ceramic materials used in dental restorations. This process densifies the zirconia particles, forming a hard, durable, and biocompatible dental prosthesis.

In the semiconductor industry, heat treatment equipment plays a crucial role in the manufacturing process, altering the physical and chemical properties of materials to meet various process requirements.

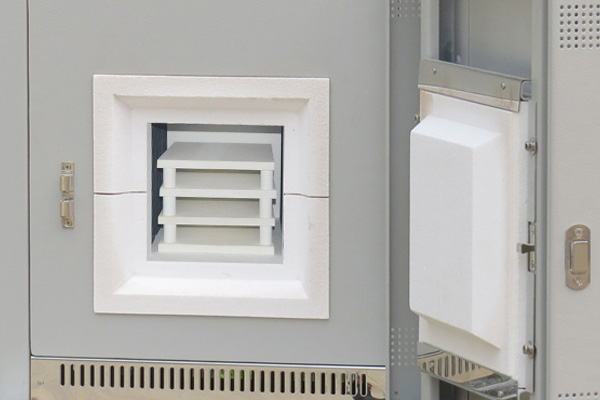

When used together in furnace furniture, alumina plates and pads create a robust solution for supporting and separating items being fired in the furnace

Laboratory furnaces serve as indispensable tools in the research and development of solid-state batteries. Their ability to provide controlled heating and cooling environments enables scientists and engineers to precisely synthesize, process, and characterize battery materials.

Furnace furniture can include crucibles, shelves, racks, supports, setters, posts, and other structures that are essential for organizing and supporting materials during heat treatment processes like firing, sintering, annealing, or heat treating.