While conventional heat treatment is widely applied in industries, vacuum heat treatment has become essential for high-precision and high-performance applications. This article explores the differences between conventional and vacuum heat treatment, including furnace types, process methods, and practical considerations.

Tag Archives: Vacuum Furnace

When it comes to working at temperatures above 1000°C, what’s happening around your material can be just as important as what’s happening to it. That’s where atmosphere control comes in — a silent, invisible force that shapes everything from material quality to process safety.

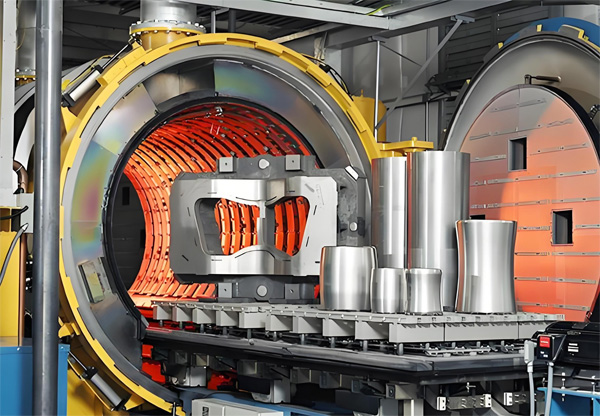

Vacuum furnaces have become indispensable tools in modern material preparation, offering high-purity environments and accurate temperature control. From advanced ceramics to semiconductor wafers, vacuum furnaces play a vital role in producing high-quality materials that meet the demanding standards of today’s industries.

In the semiconductor industry, heat treatment equipment plays a crucial role in the manufacturing process, altering the physical and chemical properties of materials to meet various process requirements.