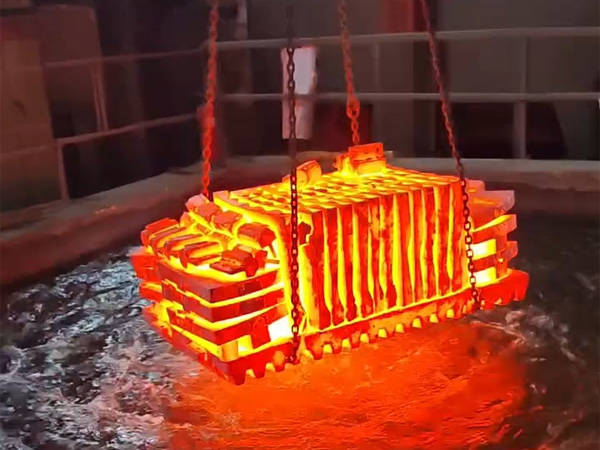

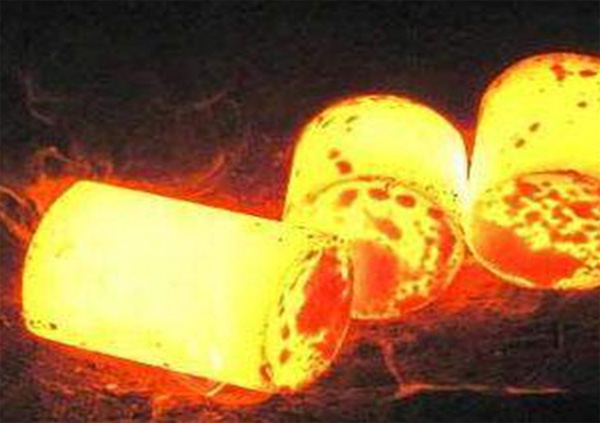

Quenching is a key heat treatment process designed to achieve extreme hardness through rapid cooling. By quickly lowering the temperature, metals and alloys transform their microstructure, locking in strength and wear resistance. In this article, we explore the principles and techniques of quenching, revealing how speed and precision create high-performance materials.

Tag Archives: Mechanical Properties of Steel

Normalizing is another essential heat treatment process used in metallurgy and materials engineering. In this article, we continue our Heat Treatment Series by explaining the definition, purpose, and unique features of normalizing, while also comparing it to annealing.