Using a mini tube furnace safely requires careful attention to pressure control, gas flow, temperature calibration, and material purity. Following these precautions will help you achieve reliable high-temperature sintering results, protect the furnace from damage, and maintain a safe laboratory environment.

Tag Archives: Laboratory Furnace

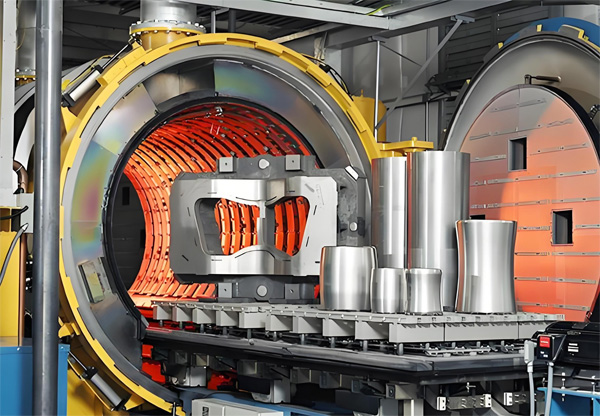

While conventional heat treatment is widely applied in industries, vacuum heat treatment has become essential for high-precision and high-performance applications. This article explores the differences between conventional and vacuum heat treatment, including furnace types, process methods, and practical considerations.

Clean-chamber vacuum atmosphere bottom-loading furnaces provide the precision, cleanliness, and automation needed to advance research at the interface of nanotechnology and enzyme catalysis. By enabling contamination-free processing, uniform heating, and flexible atmosphere control, these furnaces are accelerating progress in energy, medicine, catalysis, and sustainable chemistry.

Muffle furnaces are essential tools in modern materials research, especially for ceramic and metal sintering applications. In research and development (R&D) laboratories, where precision, repeatability, and control are paramount, muffle furnaces provide the reliable thermal environment necessary for studying advanced materials and developing new processes.

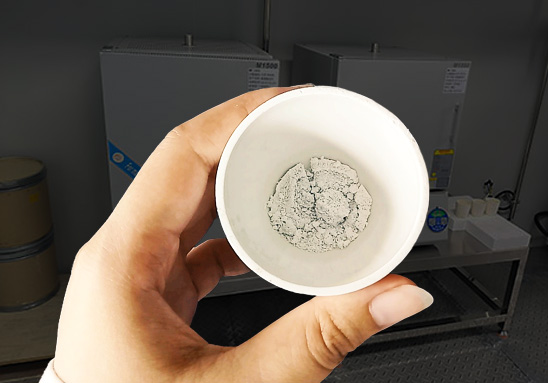

Ash content testing is a crucial process in material analysis across industries such as metallurgy, environmental science, and food safety. A muffle furnace is one of the most commonly used instruments for this task due to its ability to provide stable, high-temperature conditions for complete combustion of organic matter.

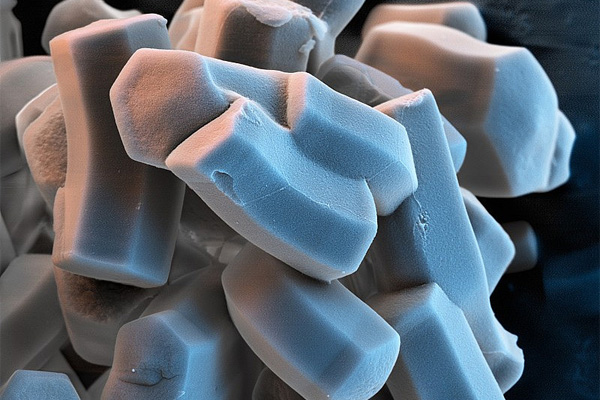

Porous materials are widely used in catalysis, gas storage, separation technologies, and energy storage due to their high surface area, tunable pore structures, and excellent chemical stability. Among them, Metal-Organic Frameworks (MOFs) and silica (SiO₂) are two of the most prominent representatives. Thermal treatment plays a crucial role in optimizing their structural and functional properties.

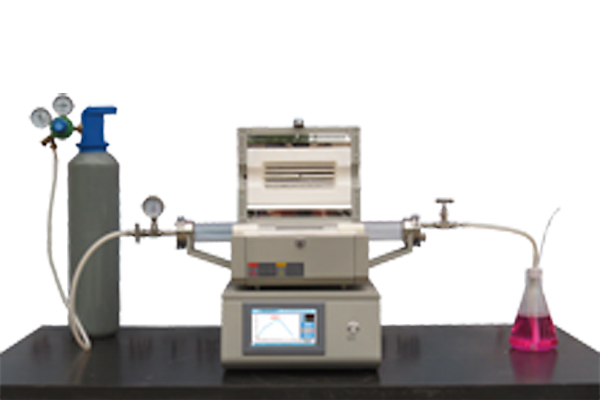

Both muffle furnaces and tube furnaces serve essential roles in high-temperature applications, but choosing the right one depends on your specific needs. If you require a chamber-style furnace for bulk materials, a Muffle Furnace is the best choice. However, if you need controlled atmospheres and precise gas flow for your experiments, a Tube Furnace is more suitable.

Vacuum tube furnaces are versatile tools for materials processing, heat treatment, and various research applications.

Two zone tube furnace used in various industrial, research, and laboratory settings for processes like material synthesis, heat treatment, and more.

Tubular furnaces are versatile tools for high-temperature applications, materials processing, and various research processes.