In the era of advanced materials and renewable energy technologies, research on metal oxide powders under high-temperature reducing conditions has become a core focus for universities, research institutes, and industrial R&D labs. To support such cutting-edge studies, ZYLAB has delivered a custom rotary hydrogen furnace to a leading Asian technical university, specifically designed for powder research.

Tag Archives: Hydrogen reduction furnace

For enterprises in the precious metals industry, the adoption of a hydrogen reduction furnace represents a leap forward in both technology and sustainability. By delivering higher efficiency, superior product purity, and reduced environmental impact, this equipment has become an indispensable tool for forward-thinking companies.

One of the most effective methods for achieving high-purity semiconductor materials is hydrogen purge reduction in a controlled furnace environment. Hydrogen purge reduction furnaces provide an optimal atmosphere to remove oxides and impurities from semiconductor materials, thereby enhancing electrical properties and improving overall device efficiency.

In the field of materials science and metallurgy, hydrogen reduction furnaces play a critical role in the purification and reduction of precious metals. These furnaces provide a controlled high-temperature environment under a hydrogen atmosphere, facilitating the removal of oxides and other impurities from valuable metals such as gold, silver, platinum, palladium, and rhodium.

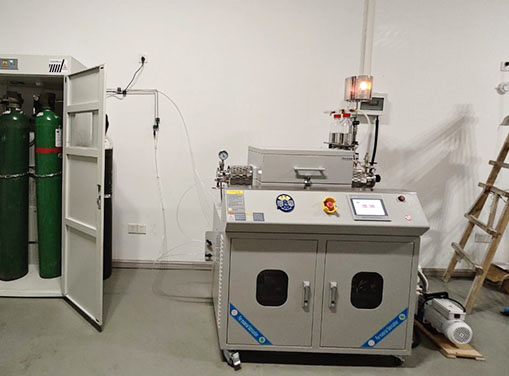

The reduction furnace is the core equipment in the hydrogen reduction process of metal oxides, providing a high-temperature environment and stable gas flow to facilitate the reduction reaction of metal oxides.