Sintering under a reducing atmosphere (e.g., H₂, forming gas, N₂/H₂ blends) offers crucial benefits— oxide removal, improved densification, enhanced mechanical properties — for metal and ceramic powders. This article reviews the mechanism, process parameters, advantages, limitations, and application guidelines of high‑temperature reducing‑atmosphere sintering, providing a reference for researchers and industrial practitioners.

Tag Archives: High-temperature sintering

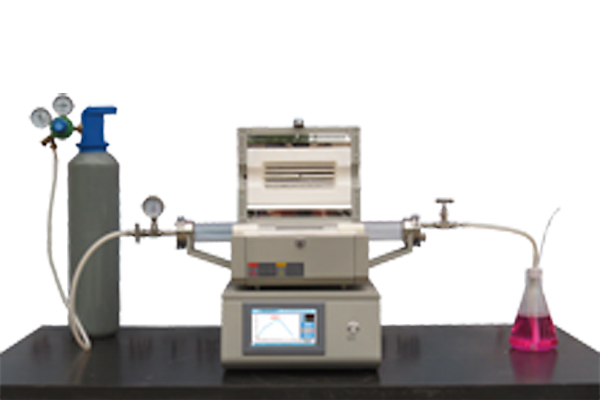

Using a mini tube furnace safely requires careful attention to pressure control, gas flow, temperature calibration, and material purity. Following these precautions will help you achieve reliable high-temperature sintering results, protect the furnace from damage, and maintain a safe laboratory environment.

From laboratory-scale research to large-scale industrial production, selecting the right sintering method is essential for optimizing material performance.

Cylindrical cell find widespread use in various applications, including portable electronic devices, power tools, electric vehicles, and energy storage systems.