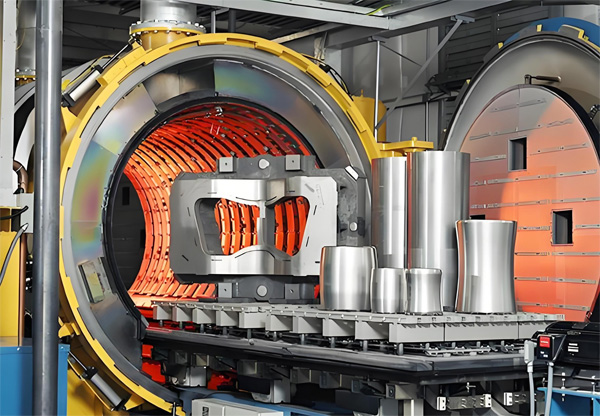

While conventional heat treatment is widely applied in industries, vacuum heat treatment has become essential for high-precision and high-performance applications. This article explores the differences between conventional and vacuum heat treatment, including furnace types, process methods, and practical considerations.

Tag Archives: Heat Treatment

Tempering is the essential follow-up step after quenching, ensuring metals are not only strong but also reliable in daily use. By carefully selecting the tempering temperature and furnace type, engineers can fine-tune hardness, toughness, and ductility to match specific applications.

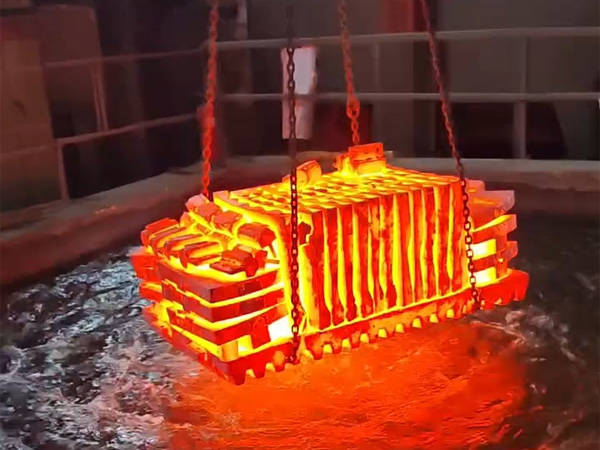

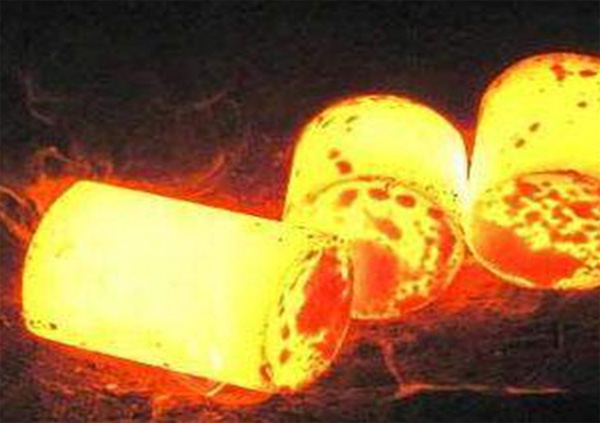

Quenching is a key heat treatment process designed to achieve extreme hardness through rapid cooling. By quickly lowering the temperature, metals and alloys transform their microstructure, locking in strength and wear resistance. In this article, we explore the principles and techniques of quenching, revealing how speed and precision create high-performance materials.

Normalizing is another essential heat treatment process used in metallurgy and materials engineering. In this article, we continue our Heat Treatment Series by explaining the definition, purpose, and unique features of normalizing, while also comparing it to annealing.

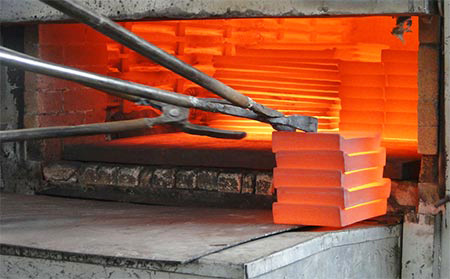

Annealing is one of the fundamental heat treatment processes widely used in metallurgy, materials science, and industrial manufacturing. In this Heat Treatment series, we explore the definition, purpose, types, and essential knowledge about annealing.

When it comes to working at temperatures above 1000°C, what’s happening around your material can be just as important as what’s happening to it. That’s where atmosphere control comes in — a silent, invisible force that shapes everything from material quality to process safety.