Sintering under a reducing atmosphere (e.g., H₂, forming gas, N₂/H₂ blends) offers crucial benefits— oxide removal, improved densification, enhanced mechanical properties — for metal and ceramic powders. This article reviews the mechanism, process parameters, advantages, limitations, and application guidelines of high‑temperature reducing‑atmosphere sintering, providing a reference for researchers and industrial practitioners.

Tag Archives: Controlled atmosphere furnace

This article delves into the technical role of high-temperature tube furnaces in carbon-based composite synthesis, focusing on temperature control, atmosphere management, and material uniformity—critical parameters for researchers and engineers in advanced material science.

When it comes to working at temperatures above 1000°C, what’s happening around your material can be just as important as what’s happening to it. That’s where atmosphere control comes in — a silent, invisible force that shapes everything from material quality to process safety.

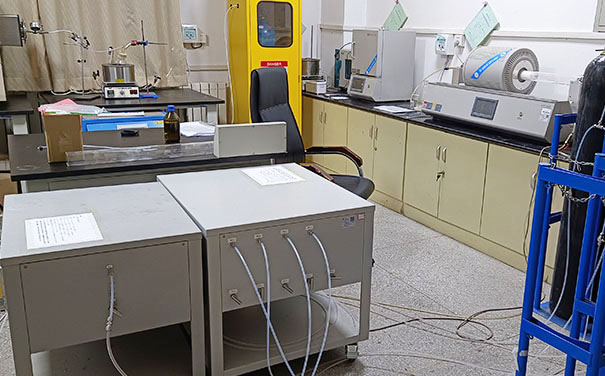

In material science research, precise temperature and atmospheric control are crucial for developing materials with enhanced properties. A university’s materials science department recently integrated a 1700℃ vacuum atmosphere furnace into their research facilities, significantly advancing new ceramic material development and metal heat treatment studies.