Table of Contents

Blog Content

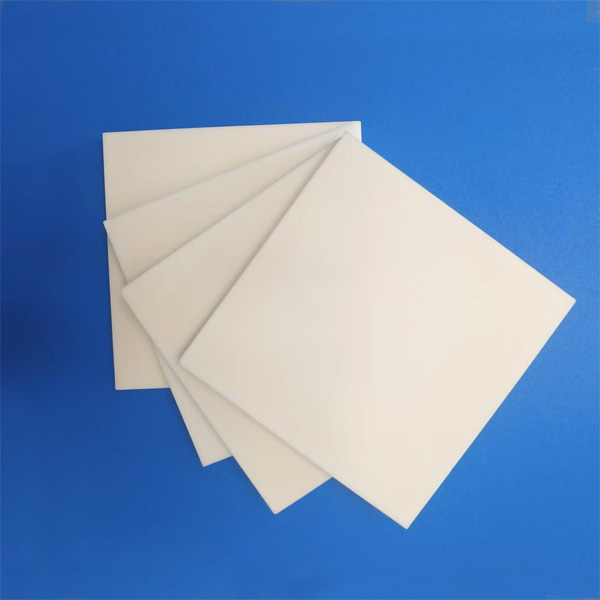

At ZYLAB, we are proud to support leading global enterprises with advanced ceramic materials. Recently, we successfully delivered a batch of high-purity alumina ceramic setter plates to TUSAŞ Engine Industries Inc. (TEI), Turkey’s leading aerospace engine manufacturer.

About the Client – TEI

TEI (TUSAŞ Engine Industries Inc.) is a globally recognized company specializing in the design, production, and maintenance of aircraft engines and gas turbines. With extensive experience in precision engineering, TEI requires materials that can withstand high-temperature, high-load, and critical tolerance conditions — especially during thermal treatments and sintering of aerospace components.

Project Requirement

TEI required ceramic setter plates to support their component sintering process inside high-temperature furnaces. Their key requirements included:

- Excellent flatness and dimensional stability

- High resistance to thermal shock

- No deformation at temperatures exceeding 1600°C

- Compatibility with a vacuum or controlled atmosphere environment

ZYLAB’s Solution

To meet TEI’s needs, ZYLAB supplied custom-sized alumina ceramic setter plates with the following features:

- Material: more than 99% high-purity Al₂O₃

- Max Working Temperature: Up to 1700°C

- Precision Machining: ±0.2 mm tolerance, surface-ground

- Excellent Thermal Shock Resistance: Ideal for rapid heating and cooling cycles

- Dense & Smooth Surface: Reduces adhesion during sintering

All plates were carefully packaged in anti-friction and anti-breakage layers to ensure safe international transit.

Application Scenario

These ceramic setter plates are being used for:

- High-temperature sintering of precision ceramic and metallic components

- Support structures in box furnaces and vacuum furnaces

- Heat treatment steps in turbine blade and engine part manufacturing

- Applications requiring flat, stable, non-reactive surfaces at elevated temperatures

Why Choose ZYLAB?

- ✅ Expertise in High-Temperature Field

Over a decade of experience supplying advanced furnaces and ceramic components to aerospace, electronics, and materials science industries. - ✅ Customization for Demanding Applications

Precision machining available for sizes, thickness, flatness, and tolerance control, tailored to each client’s specific furnace and process requirements. - ✅ Reliable Global Logistics

Professional export packaging and door-to-door delivery ensure your products arrive safely and on time, anywhere in the world. - ✅ Trusted by Industry Leaders

Proven track record supplying world-class organizations, including TEI, with consistent product quality and responsive technical support.

Need Custom Ceramic Setter Plates for Your High-Temp Process?

Contact ZYLAB today to discuss your technical requirements. Whether it’s for aerospace, metallurgy, or advanced ceramics research research or production, we offer precision-engineered ceramic components tailored to your application.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!