Table of Contents

In laboratory-scale battery research, the performance, consistency, and reliability of experimental results are strongly influenced by how well powder materials are mixed. Whether developing new cathode and anode materials, solid-state electrolytes, or conductive composites, researchers rely on homogeneous powder mixing to ensure accurate electrochemical evaluation and reproducible data.

As battery materials become increasingly complex—often involving multi-component systems with large density and particle size differences—powder mixing has become a critical yet frequently underestimated step in laboratory workflows. This article explores common powder mixing challenges in battery research, suitable laboratory mixing methods, and best practices to achieve consistent and reproducible results.

Why Powder Mixing Is Critical in Battery Research

Battery electrode and electrolyte materials are typically composed of multiple powder components, such as:

-

Active materials (e.g., NMC, LFP, LCO, silicon, graphite)

-

Conductive additives (carbon black, CNTs, graphene)

-

Solid electrolytes or functional fillers

-

Dopants or surface-modifying agents

Even small inhomogeneities in powder distribution can lead to:

-

Localized variations in electrochemical performance

-

Inconsistent capacity, rate capability, or cycle life

-

Poor reproducibility between experimental batches

-

Misinterpretation of material properties during research

For laboratory researchers, achieving uniform powder mixing without altering particle structure or chemistry is essential.

Common Challenges in Mixing Battery Powder Materials

Density and Particle Size Differences

Battery powders often vary widely in density and particle size. For example, lightweight conductive carbon additives tend to segregate easily when mixed with heavier metal oxide active materials.

Agglomeration of Fine Powders

Nano-scale or sub-micron powders, such as carbon black or solid electrolytes, are prone to agglomeration due to van der Waals forces, making uniform dispersion difficult.

Sensitivity to Mechanical Stress

Many battery materials are sensitive to excessive shear or impact. High-energy mixing may cause particle fracture, surface damage, or unintended changes in crystal structure.

Moisture and Air Sensitivity

Certain battery materials—especially lithium-containing compounds and solid electrolytes—are highly sensitive to moisture and oxygen, requiring controlled or sealed mixing environments.

Laboratory Powder Mixing Methods for Battery Research

Several mixing techniques are commonly used in battery research laboratories, each with distinct advantages and limitations.

Ball Milling

Ball milling provides intensive mixing and particle size reduction, but it may introduce contamination, excessive heat, or unwanted structural changes. It is more suitable for mechanical alloying than simple blending.

Mortar and Pestle

Manual mixing is simple but lacks reproducibility and is unsuitable for multi-component systems or systematic research studies.

V-Type or Tumble Mixers

These mixers offer low-shear mixing but may struggle with density-driven segregation in complex battery powder formulations.

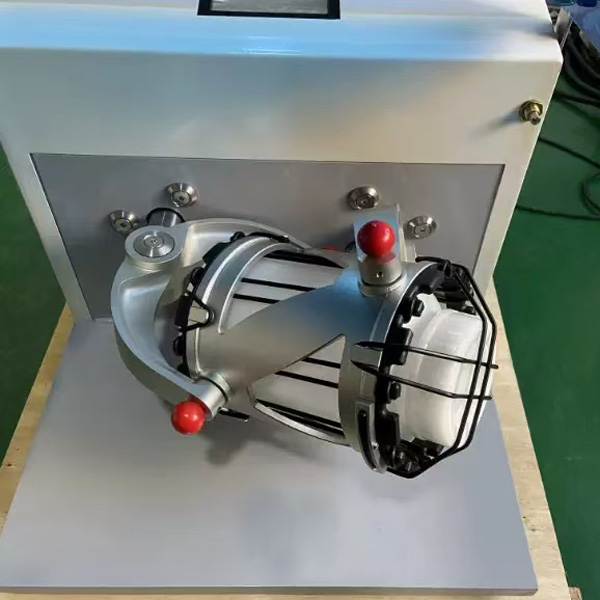

Lab-Scale 3D Shaker Mixers

Lab-scale 3D shaker mixers use gentle three-dimensional motion to continuously reorient powder materials, enabling uniform mixing without high mechanical stress. This makes them particularly suitable for battery research applications where powder integrity and reproducibility are critical.

Advantages of 3D Shaker Mixing for Battery Materials

-

Uniform dispersion of conductive additives without damaging active materials

-

Low shear and low heat generation, preserving particle morphology

-

Reduced segregation in multi-density powder systems

-

Sealed container operation, compatible with inert gas or glove box workflows

-

Excellent batch-to-batch reproducibility, ideal for academic and industrial R&D

These characteristics make 3D shaker mixing especially attractive for preparing electrode powders, solid electrolyte blends, and composite battery materials at laboratory scale.

Best Practices for Mixing Battery Powders in the Laboratory

Select Appropriate Containers

Use containers made of stainless steel, PTFE, or antistatic polymers. For moisture-sensitive materials, ensure containers are well sealed and compatible with inert gas purging.

Optimize Fill Ratio

A fill level of 30–70% of container volume typically provides effective powder movement and mixing uniformity.

Control Mixing Time and Intensity

Start with short mixing times (e.g., 5–15 minutes) and adjust based on material behavior. Avoid excessive mixing energy that may cause particle damage or segregation.

Consider Atmosphere Control

For air- or moisture-sensitive battery materials, mixing can be performed in sealed containers under argon or nitrogen, or inside a glove box environment.

Verify Mixing Homogeneity

Analytical methods such as SEM/EDS, particle size analysis, or electrochemical consistency testing can be used to confirm uniform powder distribution.

Applications in Battery Research Laboratories

Laboratory powder mixing is widely used in:

-

Cathode and anode material development

-

Solid-state battery research

-

Conductive additive dispersion studies

-

Composite electrode formulation

-

Screening and optimization of new battery chemistries

Reliable powder mixing directly contributes to faster material screening, improved data quality, and more meaningful research conclusions.

Conclusion

Powder mixing is a foundational step in laboratory battery research, directly influencing electrochemical performance and experimental reproducibility. Choosing the right mixing method—particularly low-shear, reproducible solutions such as lab-scale 3D shaker mixers—can significantly improve material preparation quality while preserving powder integrity.

By adopting best practices in container selection, mixing parameters, and atmosphere control, researchers can ensure consistent and reliable powder formulations, supporting high-quality battery research and development.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!