Table of Contents

Powder material fibrillation is a key technique in advanced materials research, enabling the transformation of powders into fiber-like structures with enhanced surface area, mechanical strength, and functional properties. Fibrillated powders are widely used in composites, energy materials, filtration, and additive manufacturing.

This article provides a research-focused overview of powder material fibrillation, covering mechanisms, materials, processing methods, and typical applications, including laboratory-scale studies using jet milling equipment such as the Lab Scale Jet Mill.

What Is Powder Material Fibrillation?

Powder material fibrillation refers to the process of converting micron- or nano-scale powders into elongated fibers through mechanical, chemical, or thermomechanical methods. Fibrillated powders typically feature:

-

High aspect ratio (length-to-diameter ratio)

-

Increased surface area

-

Enhanced interfacial bonding in composites

-

Tailorable porosity and morphology

Fibrillated powders improve dispersibility, mechanical reinforcement, and functional performance compared with granular powders.

Mechanisms of Fibrillation

Fibrillation can occur through different mechanisms depending on material type and processing technique:

1. Mechanical Shear-Induced Fibrillation

High shear forces stretch particles into fiber-like structures. In laboratory research, jet milling—such as experiments conducted with the Lab Scale Jet Mill—provides controlled particle collisions that can produce uniform fibrillated powders for polymers, ceramics, and biomass materials.

2. Thermomechanical Fibrillation

Heating near the glass transition temperature softens materials, enabling fiber formation during milling, extrusion, or stretching processes.

3. Chemical Fibrillation

Chemical treatments, selective dissolution, or surface etching can modify particle morphology to promote fibrillation. This is commonly applied to cellulose, graphene, and metal-organic powders.

4. Electrospinning-Assisted Fibrillation

Electrospinning can convert powder-like precursors into nanoscale fibrils with controlled morphology.

Materials Suitable for Fibrillation

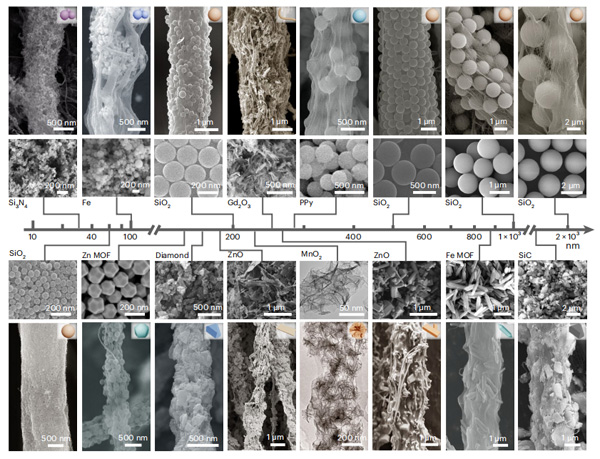

A wide range of powders can be fibrillated in the lab:

-

Polymers: PTFE, PEEK, nylon precursors

-

Inorganic powders: alumina, silica, zirconia

-

Carbon-based powders: graphene, carbon nanotubes, carbon black composites

-

Biomass powders: cellulose, chitin

-

Metal powders: Ni, Fe, TiO₂ for catalysis or energy applications

Laboratory-scale jet milling systems, such as the ZYLAB Lab Scale Jet Mill, are frequently used to study these materials under controlled conditions, allowing researchers to explore the effects of milling parameters on fiber morphology and aspect ratio.

Benefits of Fibrillated Powders

-

Increased surface area: Enhances catalytic activity, adsorption, and reaction rates

-

Improved mechanical reinforcement: Better stress transfer and interfacial adhesion in composites

-

Enhanced porosity and filtration efficiency: Useful for membranes, separators, and lab-scale filtration

-

Superior dispersion stability: Reduces agglomeration in polymer melts, ceramic slurries, or suspensions

-

Tunable functionality: Fiber morphology can be engineered for thermal, electrical, or chemical performance

Processing Techniques for Fibrillation

-

High-shear milling or jet milling: Uses particle collisions to generate fiber-like structures. Lab-scale jet mills, including the ZYLAB Lab Scale Jet Mill, allow precise control of particle velocity, collision intensity, and feed rate.

-

Cryogenic grinding: Prevents thermal degradation for temperature-sensitive powders

-

Hot pressing and stretching: Common for polymer-based fillers

-

Solvent-assisted swelling: Enables controlled fibrillation of cellulose, carbon, and hybrid powders

-

Electrospinning/electrospraying: Produces ultra-fine nano-fibrils with controllable morphology

Applications of Fibrillated Powders

1. Advanced Composites

Fibrillated powders enhance tensile strength, impact resistance, and thermal stability of polymer or ceramic matrices.

2. Energy Materials

High-surface-area fibers are used in lithium-ion battery separators, solid electrolytes, and conductive additive networks.

3. Filtration and Separation

Fiber networks provide high porosity and fine-particle capture for membranes and lab-scale filtration systems.

4. Catalysis

Enhanced surface area increases reaction efficiency in catalytic materials.

5. Additive Manufacturing

Fibrillated powders improve interlayer bonding and mechanical performance in 3D-printed materials.

6. Thermal Insulation and Functional Coatings

Fiber morphology can reduce thermal conductivity and improve durability in coatings.

Research Trends

-

Nano-fibrillated composites combining carbon and ceramic fillers

-

Bio-based fibrillated materials for sustainable engineering

-

Lightweight structural materials for aerospace and automotive applications

-

Advanced process control for reproducible fibrillation

-

High-temperature sintering and post-processing of fibrillated powders

Conclusion

Powder material fibrillation is a fundamental technique for producing fiber-like powders with enhanced mechanical, thermal, and functional properties. Understanding the mechanisms, material selection, and processing methods is essential for researchers developing advanced composites, energy materials, and filtration systems.

Laboratory-scale equipment, such as jet milling systems, provides a controlled environment for studying fibrillation processes and optimizing fiber morphology in research applications.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!