Table of Contents

Introduction

In laboratory powder milling, selecting the correct grinding media—both the ball mill jar and the grinding balls

This guide provides laboratory researchers with a practical overview of grinding media materials, their properties, and recommended applications. ZYLAB offers a comprehensive range of ball mill jars and balls, making it easier to match the right media to your research needs.

Why Grinding Media Selection Matters

-

Contamination control: Avoid unwanted elements leaching into your powder.

-

Material compatibility: Match jar and ball hardness to the sample material.

-

Efficiency: Harder media reduce milling time for tough materials.

-

Purity and yield: Certain applications (e.g., pharmaceuticals, high-purity ceramics) demand inert, ultra-clean grinding.

-

Mechanical stability: The jar material must withstand impact and prevent cracking or excessive wear.

ZYLAB Ball Mill Jar Materials

1. Stainless Steel Ball Mill Jar

-

Properties: High strength, durable, cost-effective.

-

Best for: Metallic powders, alloys, hard minerals.

-

Limitations: Risk of Fe contamination; not suitable for ultra-pure ceramics.

-

Recommended balls: Stainless steel balls.

2. Tungsten Carbide Ball Mill Jar

-

Properties: Extreme hardness, excellent wear resistance.

-

Best for: Very hard materials, alloys, electronic materials.

-

Limitations: Higher cost, heavier weight, risk of WC contamination.

-

Recommended balls: Tungsten carbide balls.

3. Alumina Ball Mill Jar

-

Properties: High hardness, wear resistance, chemical stability.

-

Best for: Oxides, ceramics, non-metallic powders.

-

Limitations: Brittle under high impact.

-

Recommended balls: Alumina balls, zirconia balls.

4. Zirconia Ball Mill Jar

-

Properties: Ultra-high wear resistance, high density, minimal contamination.

-

Best for: High-purity ceramics, pharmaceuticals, nanomaterials.

-

Limitations: More expensive than alumina.

-

Recommended balls: Zirconia balls.

5. Silicon Carbide Ball Mill Jar

-

Properties: High thermal conductivity, oxidation resistance.

-

Best for: High-temperature and abrasive powders.

-

Limitations: Brittle and relatively rare.

-

Recommended balls: Silicon carbide balls.

6. Silicon Nitride Ball Mill Jar

-

Properties: Lightweight, very strong, resistant to thermal shock.

-

Best for: Advanced ceramics, electronic materials, battery materials.

-

Limitations: Higher price point.

-

Recommended balls: Silicon nitride balls.

7. Polyurethane Ball Mill Jar

-

Properties: Flexible, impact-absorbing, low contamination.

-

Best for: Soft, ductile powders; avoids excessive abrasion.

-

Limitations: Not suitable for very hard materials.

-

Recommended balls: Polyurethane balls, PTFE balls.

8. Nylon Ball Mill Jar

-

Properties: Lightweight, inexpensive, chemical-resistant.

-

Best for: Organic compounds, softer powders, small sample volumes.

-

Limitations: Limited durability for hard abrasives.

-

Recommended balls: Nylon or polyurethane balls.

9. PTFE Ball Mill Jar

-

Properties: Chemically inert, non-stick surface.

-

Best for: Highly reactive or corrosive powders.

-

Limitations: Lower mechanical strength.

-

Recommended balls: PTFE balls.

10. Agate Grinding Jar

-

Properties: Natural stone, low contamination, high hardness.

-

Best for: Geology, minerals, small-scale research samples.

-

Limitations: Fragile under high-energy milling.

-

Recommended balls: Agate balls.

11. Vacuum/Atmosphere-Protected Ball Mill Jar

-

Properties: Allows milling under inert gas or vacuum.

-

Best for: Oxygen-sensitive, pyrophoric, or air-reactive powders (e.g., Ti, Mg).

-

Limitations: Specialized design, higher cost.

-

Recommended balls: Depends on sample and jar lining (zirconia, stainless, WC, etc.).

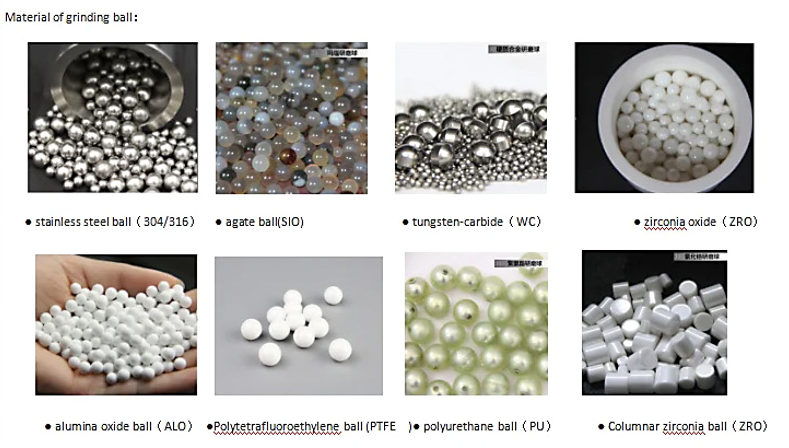

ZYLAB Grinding Balls

Available materials:

-

Agate balls: For low contamination, brittle materials.

-

Zirconium balls: High density, wear resistance, high-purity applications.

-

Stainless steel balls: Durable, cost-effective, metallic powders.

-

Polyurethane balls: Soft, low abrasion, organic powders.

-

Alumina balls: Ceramics, oxides, general laboratory use.

-

Tungsten carbide balls: Hardest option, efficient milling of strong materials.

-

PTFE balls: Corrosion resistance, reactive powders.

-

Silicon carbide balls: Abrasive and high-temperature powders.

-

Silicon nitride balls: Strong, lightweight, advanced ceramics.

Matching Guide: Which Jar & Ball for Which Material?

| Material Type | Recommended Jar | Recommended Balls |

|---|

| High-purity ceramics | Zirconia, Alumina | Zirconia, Alumina |

| Metallic powders | Stainless steel, WC | Stainless steel, WC |

| Nanomaterials | Zirconia, WC | Zirconia, WC |

| Polymers/ductile | PTFE, Polyurethane, Nylon | PTFE, Polyurethane |

| Reactive powders | Vacuum-protected jar | Depends on lining |

| Geological samples | Agate, Alumina | Agate |

| Battery materials | Zirconia, Silicon nitride | Zirconia, Si₃N₄ |

| Abrasive powders | Silicon carbide, WC | SiC, WC |

Practical Tips for Researchers

-

Avoid cross-contamination by reserving specific jars for specific powder groups.

-

Match hardness: balls should be harder than the powder, but not excessively harder than the jar.

-

Control jar size: choose jar volume to maintain the correct ball-to-powder ratio (BPR).

-

Cleaning matters: PTFE, agate, and alumina are easier to clean; WC and stainless may retain residues.

-

Consider cost vs lifetime: zirconia and WC are expensive, but last longer.

Frequently Asked Questions (FAQ)

Q: How do I prevent Fe contamination during ball milling?

A: Avoid stainless steel jars and balls; use zirconia, alumina, or agate instead.

Q: Which grinding media is best for nanomaterial synthesis?

A: High-density zirconia or tungsten carbide jars and balls.

Q: Can I use one jar for different materials?

A: Not recommended; dedicate jars to specific groups to avoid cross-contamination.

Q: What’s the most cost-effective option?

A: Stainless steel for general use; alumina jars for ceramic powders.

Q: Which media should I choose for pharmaceutical powders?

A: Zirconia jars and zirconia balls to ensure purity and reproducibility.

Conclusion

The correct grinding media ensures efficient milling, consistent particle size, and reliable experimental results. ZYLAB offers a complete portfolio of ball mill jars (stainless steel, tungsten carbide, alumina, zirconia, silicon carbide, silicon nitride, polyurethane, nylon, PTFE, agate, and vacuum-protected jars) and grinding balls.

By aligning jar and ball material with your powder type, you minimize contamination, improve yield, and enhance research reproducibility.

Contact ZYLAB today to discuss customized laboratory milling solutions tailored to your research.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!