Table of Contents

Annealing is one of the fundamental heat treatment processes widely used in metallurgy, materials science, and industrial manufacturing. In this Heat Treatment series, we explore the definition, purpose, types, and essential knowledge about annealing.

What is Annealing?

Annealing is a controlled heat treatment process in which a material, typically metal or alloy, is heated to a specific temperature, held for a certain period, and then cooled at a controlled rate. The process is designed to alter the microstructure of the material to improve its mechanical properties, reduce internal stress, and enhance workability.

Key Parameters of Annealing:

| Parameter | Typical Range | Notes |

|---|---|---|

| Heating temperature | 400°C – 800°C (for steel) | Depends on material type |

| Holding time | 1–4 hours | Based on thickness and alloy composition |

| Cooling rate | 10–50°C/hour (slow cooling in furnace) | Prevents new stresses or cracks |

Purpose of Annealing

Annealing serves several crucial purposes in material processing:

-

Stress Relief: Reduces internal stresses caused by machining, welding, or cold working.

-

Softening: Lowers hardness and increases ductility, making the material easier to shape or form.

-

Microstructure Refinement: Promotes uniform grain structure, which enhances mechanical consistency.

-

Improved Electrical and Magnetic Properties: Particularly important for materials like copper or silicon steel.

Example: Cold-rolled steel can have a hardness of 250–300 HV (Vickers Hardness). After annealing, hardness can drop to 150–180 HV, improving ductility while relieving residual stress.

Types of Annealing

Annealing can be classified based on the process and purpose:

a. Full Annealing

-

Heating Temperature: Above the material’s critical temperature (typically 750–800°C for carbon steel)

-

Cooling Method: Slow cooling in the furnace

-

Purpose: Produces a coarse-grained, soft structure with improved machinability

-

Application: Carbon steels, tool steels, and some stainless steels

b. Process Annealing (Subcritical Annealing)

-

Heating Temperature: Below the critical temperature (typically 550–650°C for low-carbon steel)

-

Cooling Method: Slow cooling in the furnace or air cooling

-

Purpose: Relieves stress from cold working without changing the phase

-

Application: Cold-worked low-carbon steels and copper alloys

c. Spheroidizing Annealing

-

Heating Temperature: Prolonged heating at 650–700°C for high-carbon steel

-

Cooling Method: Very slow cooling in the furnace

-

Purpose: Produces spheroidal carbides to maximize softness and machinability

-

Application: Gear steels and high-carbon wire rods

d. Bright Annealing

-

Heating Temperature: 600–700°C, in a controlled or protective atmosphere

-

Cooling Method: Furnace cooling or gas cooling under protective atmosphere

-

Purpose: Maintains a clean, oxide-free surface while softening the material

-

Application: Stainless steels and specialty alloys for aerospace or electronics

Key Knowledge About Annealing

-

Furnace Types: Annealing can be conducted in muffle furnaces, tube furnaces, or vacuum/controlled-atmosphere furnaces depending on material sensitivity.

- Cooling Methods: Furnace cooling, air cooling, or gas quenching can be chosen to control final microstructure.

-

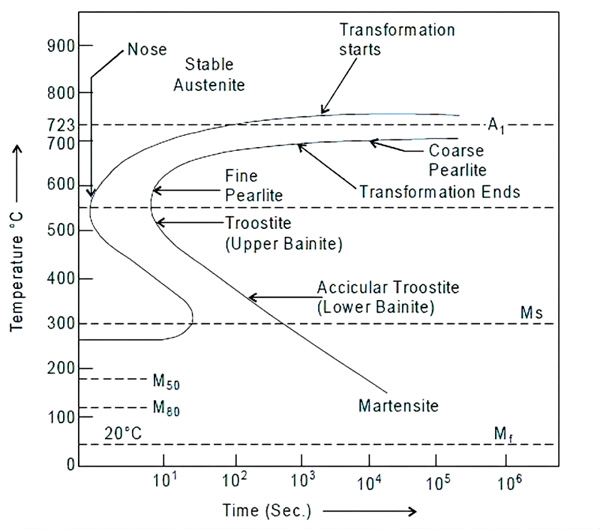

Annealing Graphs: Time-Temperature-Transformation (TTT) diagrams are essential for predicting microstructure changes.

Example TTT Diagram for Steel:

- Energy Efficiency: Modern annealing furnaces optimize heating and cooling cycles to reduce energy consumption while maintaining material quality.

Conclusion

Annealing is a versatile and essential heat treatment process that enhances material performance by modifying hardness, ductility, and microstructure. Understanding the types, purposes, and precise parameters of annealing is critical for metallurgists, material engineers, and industrial practitioners.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!