Table of Contents

In scientific research and industrial applications, fibrous materials such as carbon fibers, wood fibers, chemical fibers, and hair often need to be ground into fine powders. This is essential for micro-element analysis and for modifying these fibers into composite materials. Achieving a uniform, contaminant-free powder requires careful selection of equipment, grinding media, and process parameters.

Based on over a decade of industry experience, we provide an effective solution for grinding chemical fibers into powder:

Recommended Grinding Solution

-

Material: Chemical fibers

-

Equipment: Planetary Ball Mill (Model: M-20L)

-

Grinding Jar: 5L polyurethane jar

-

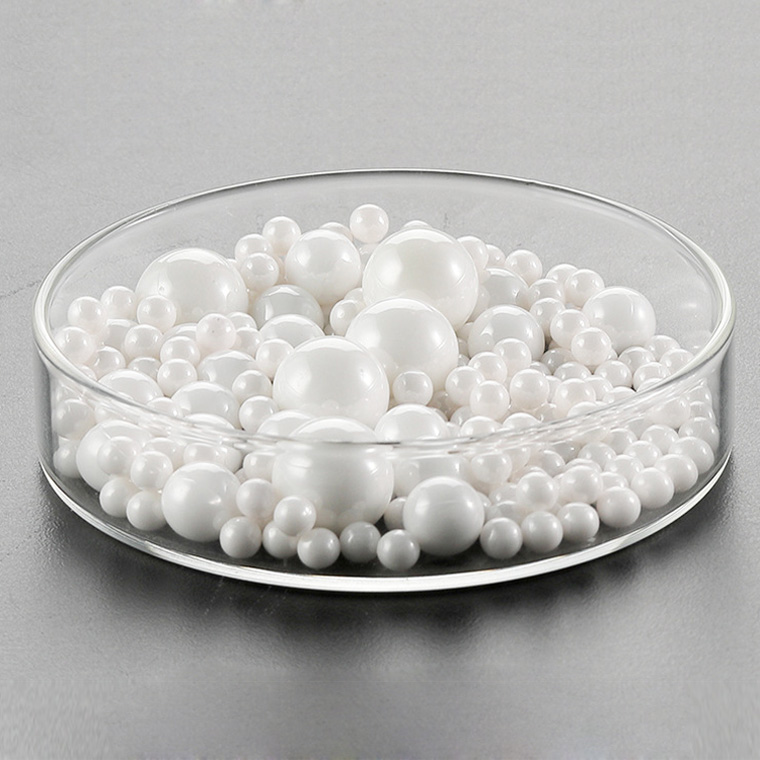

Grinding Balls: 7–15 mm zirconia balls

-

Feed Size: 50–200 mm fiber length

-

Processing Amount: 1 kg per batch

-

Grinding Time: 60 minutes

-

Rotational Speed: 520 rpm

-

Final Particle Size: ≤20 μm

-

Sample Quality: Contamination-free

Why This Solution Works

-

Planetary Ball Mill Efficiency

The M-20L planetary ball mill provides high-energy impact and efficient shear forces, which are ideal for breaking down long fibers into fine powders. -

Optimized Grinding Media

Using 7–15 mm zirconia balls ensures effective grinding while avoiding contamination. Zirconia is chemically inert and highly durable, making it perfect for sensitive fiber materials. -

Controlled Process Parameters

-

Fiber size and feed amount are carefully selected to prevent excessive clumping.

-

Grinding time and rotational speed are optimized to achieve fine particle sizes ≤20 μm without overheating or damaging the fibers.

-

-

Contamination-Free Powder

The use of a polyurethane jar avoids metal contamination, making the resulting powder suitable for micro-element analysis and composite modification experiments.

Applications

-

Micro-element Analysis: Accurate elemental testing requires fibers to be finely ground without contamination.

-

Composite Material Production: Ground fibers can be easily incorporated into polymers or resins to enhance mechanical properties.

-

Material Research: Fine powders facilitate studies on fiber surface modification, functionalization, and performance enhancement.

Conclusion

Grinding chemical fibrous materials into fine powder is a critical step for research and industrial applications. Using a planetary ball mill with zirconia grinding balls in a polyurethane jar offers a highly efficient, contamination-free, and reproducible method. This solution ensures fibers are ground to ≤20 μm, ready for elemental analysis or incorporation into advanced composite materials.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!