Aging treatment, also known as precipitation hardening, is a key step in modern heat treatment technology. This process follows solution treatment and involves heating alloys at a controlled temperature to allow the formation of fine precipitates, which strengthen the metal.

Category Archives: Heat Treatment

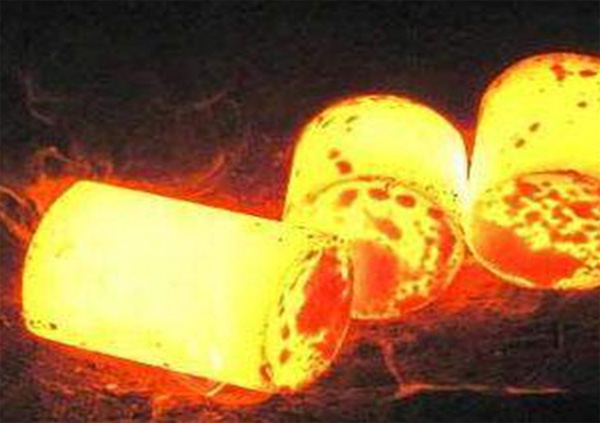

In the field of heat treatment, solution treatment (also known as solid solution treatment) is a critical process for improving the mechanical and corrosion-resistant properties of metals, especially stainless steels, nickel-based alloys, and aluminum alloys. The process involves heating the alloy to a high temperature to dissolve alloying elements into a solid solution, followed by rapid cooling to retain this uniform structure.

Quenching and tempering, commonly known as “tempering after quenching” or “quench-temper treatment”, is a fundamental heat treatment process used to optimize the mechanical properties of steel. This article explores what quenching and tempering is, its purpose, how it differs from simple quenching, and essential technical considerations for researchers and engineers.

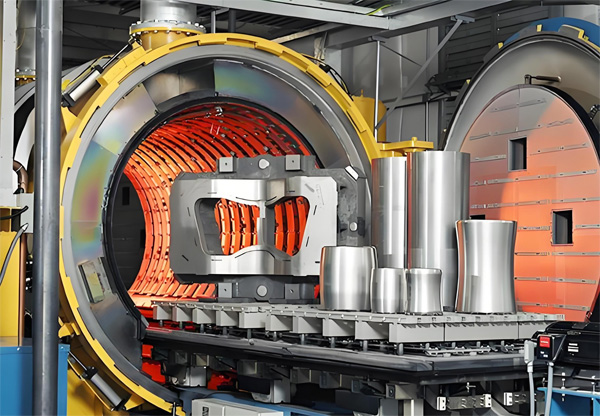

While conventional heat treatment is widely applied in industries, vacuum heat treatment has become essential for high-precision and high-performance applications. This article explores the differences between conventional and vacuum heat treatment, including furnace types, process methods, and practical considerations.

While conventional heat treatment methods like annealing, normalizing, and quenching alter the bulk properties of a material, carburizing and nitriding focus on the surface layer, creating a hard, wear-resistant shell while maintaining a tough and ductile core.

Tempering is the essential follow-up step after quenching, ensuring metals are not only strong but also reliable in daily use. By carefully selecting the tempering temperature and furnace type, engineers can fine-tune hardness, toughness, and ductility to match specific applications.

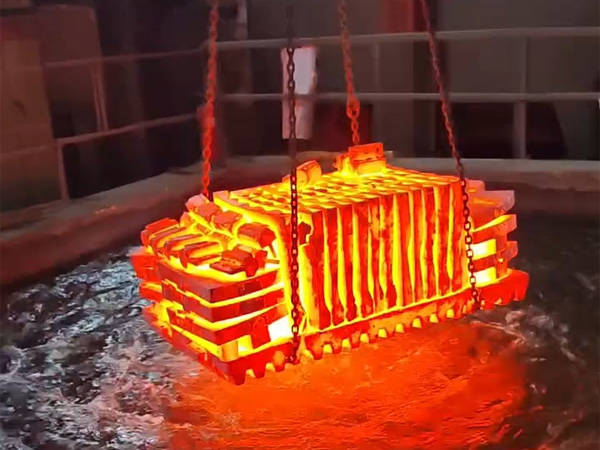

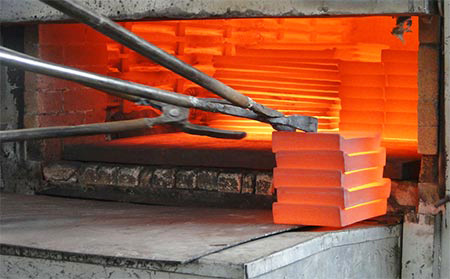

Quenching is a key heat treatment process designed to achieve extreme hardness through rapid cooling. By quickly lowering the temperature, metals and alloys transform their microstructure, locking in strength and wear resistance. In this article, we explore the principles and techniques of quenching, revealing how speed and precision create high-performance materials.

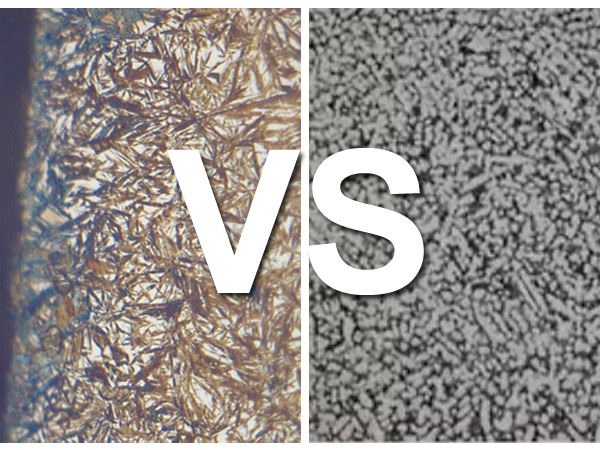

Normalizing is another essential heat treatment process used in metallurgy and materials engineering. In this article, we continue our Heat Treatment Series by explaining the definition, purpose, and unique features of normalizing, while also comparing it to annealing.

Annealing is one of the fundamental heat treatment processes widely used in metallurgy, materials science, and industrial manufacturing. In this Heat Treatment series, we explore the definition, purpose, types, and essential knowledge about annealing.