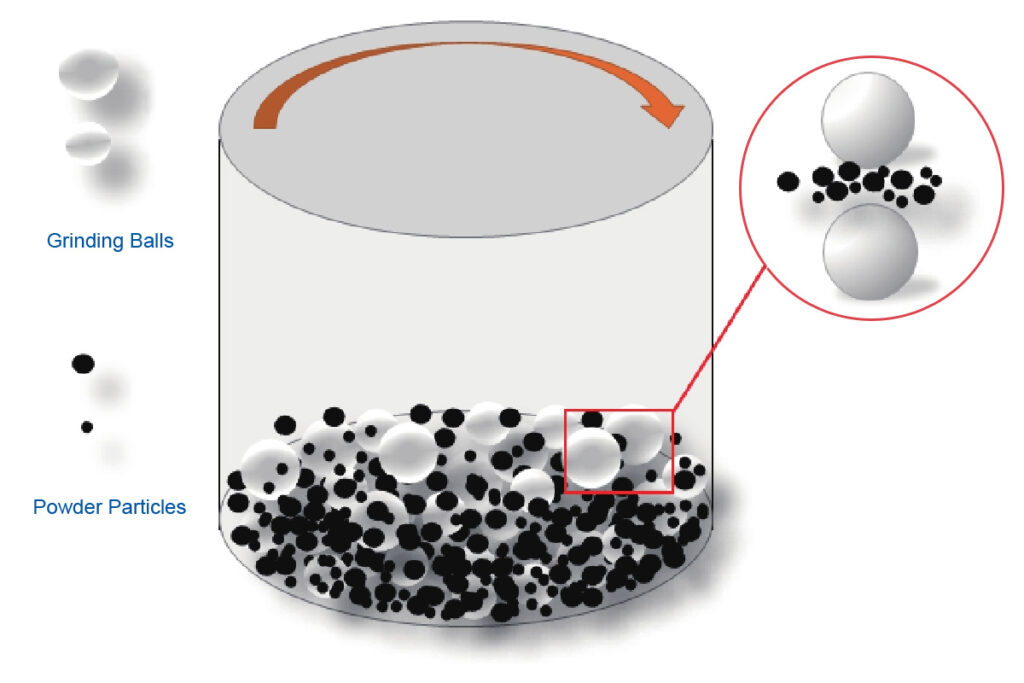

This article explains the main reasons behind incomplete size reduction in ball milling and provides practical solutions to improve grinding efficiency.

Category Archives: Grinding

Understanding the role of grinding ball size distribution is critical for improving milling efficiency, controlling particle size, and achieving reproducible results. This article explains both the scientific reasons behind using multiple grinding ball sizes and practical guidelines for selecting the right grinding media.

In scientific research and industrial applications, fibrous materials such as carbon fibers, wood fibers, chemical fibers, and hair often need to be ground into fine powders. This is essential for micro-element analysis and for modifying these fibers into composite materials. Achieving a uniform, contaminant-free powder requires careful selection of equipment, grinding media, and process parameters.

This article provides a research-focused overview of powder material fibrillation, covering mechanisms, materials, processing methods, and typical applications, including laboratory-scale studies using jet milling equipment such as the Lab Scale Jet Mill.

This guide provides laboratory researchers with a practical overview of grinding media materials, their properties, and recommended applications. ZYLAB offers a comprehensive range of ball mill jars and balls, making it easier to match the right media to your research needs.

This guide explains how the most commonly used lab mills work, which powder types each is best suited for, and practical tradeoffs lab researchers should consider.

At ZYLAB, we take pride in supporting academic excellence by delivering high-quality laboratory equipment to leading universities around the world. We are pleased to announce the successful delivery of a planetary ball mill to the prestigious University of Southampton in the United Kingdom.

Mechanical alloying refers to a powder preparation technique in which metal or alloy powders are subjected to prolonged, intense impacts and collisions between powder particles and milling balls in a high-energy planetary ball mill. This process causes repeated cold welding and fracturing of the powder particles, leading to atomic diffusion within the powder particles and resulting in alloyed powders.

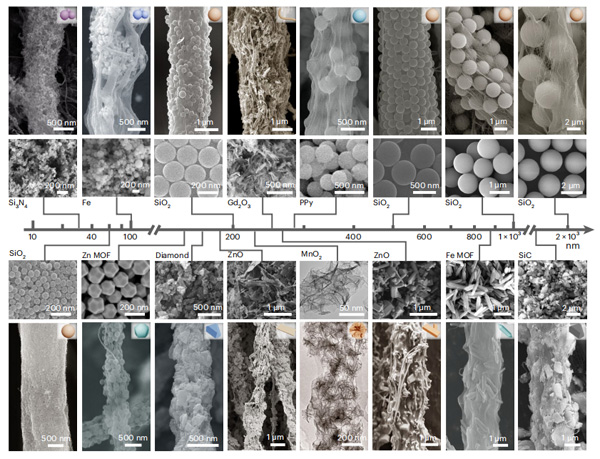

High-energy ball mills are suitable for grinding various materials, including nanomaterials, electronic component materials, oxide materials, ferrites and magnetic materials, battery materials, catalysts and chemicals, metallurgical and mineral materials, luminescent materials, as well as glass materials.

In the realm of modern manufacturing, Powder Metallurgy (PM) stands out as an innovative and efficient production method, gaining popularity across various industries. By utilizing metal powders or a mixture of metal and non-metal powders, this technique involves pressing and sintering to create high-precision, high-performance metal components.

- 1

- 2