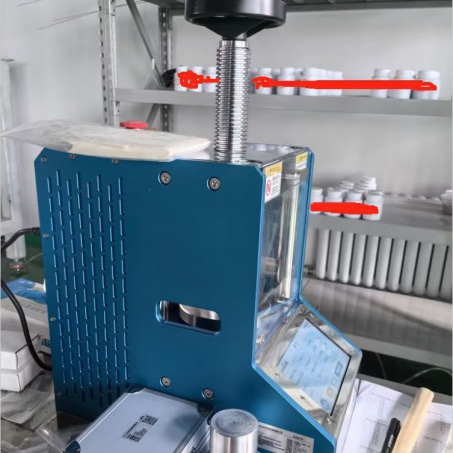

How to Fill Hydraulic Oil for a Powder Pellet Press Machine

Proper hydraulic oil filling is essential to ensure the stable operation, pressing accuracy, and long service life of a powder pellet press machine. Whether you are using a 20-ton, 30-ton, or 100-ton fully automatic powder pellet press or other models, correct oil filling and maintenance are key to reliable performance and smooth operation.