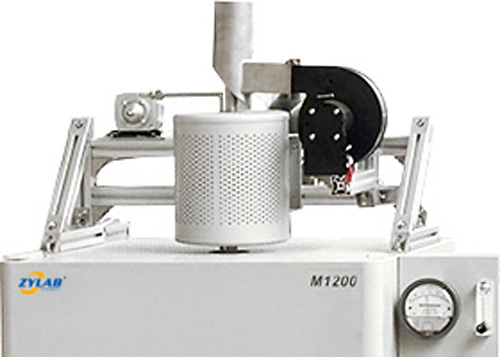

Supplying Lab Scale Jet Mill to a Leading U.S. Cement R&D Company

In advanced cement research, precision powder processing is essential for material development, performance evaluation, and formulation innovation. ZYLAB recently supplied a Lab Scale Jet Mill to a leading U.S. cement research company for small-batch ultra-fine grinding, enabling more accurate and consistent R&D results.