Distillation Solutions

Applications:

Solvent Removal

Purification

Extraction

Sample Preparation

Applications:

Solvent Removal

Purification

Extraction

Sample Preparation

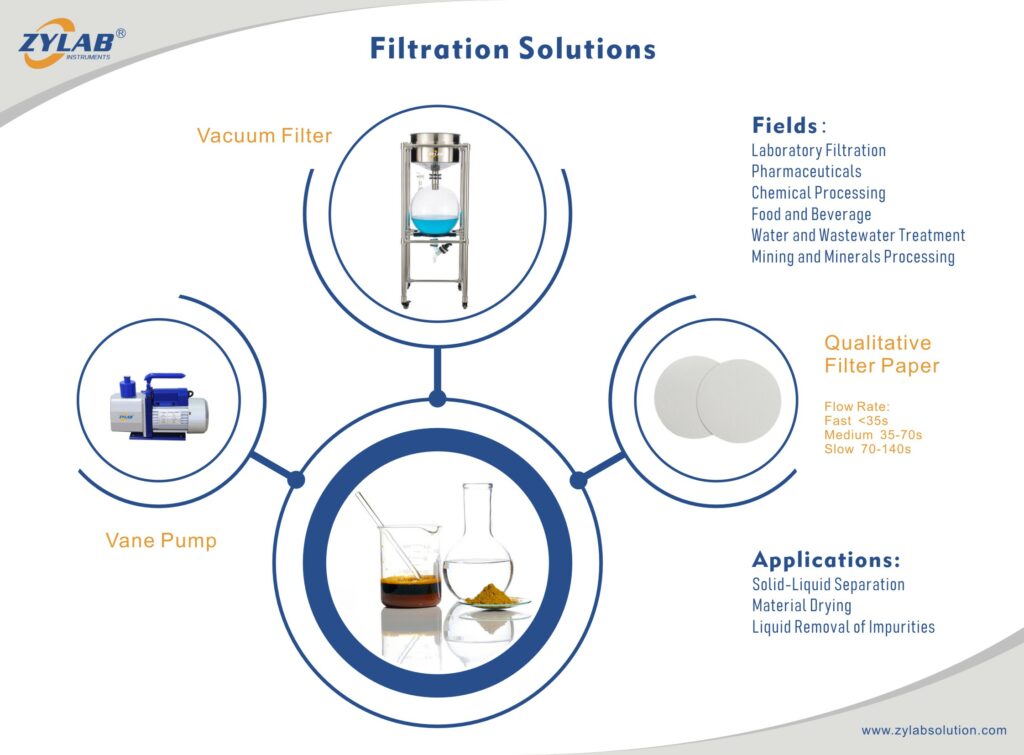

Applications:

Solid-liquid Separation

Material Drying

Liquid Removal of Impurities

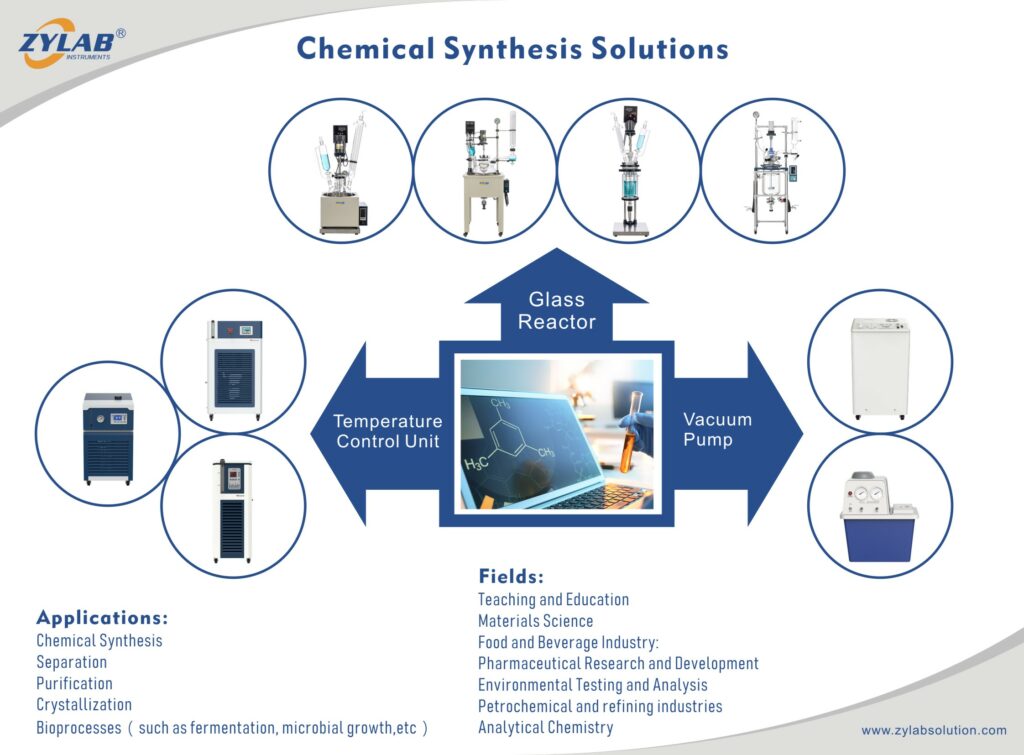

Applications:

Chemical Synthesis

Separation

Purification

Crystallization

Bioprocesses: such as fermentation, microbial growth,etc

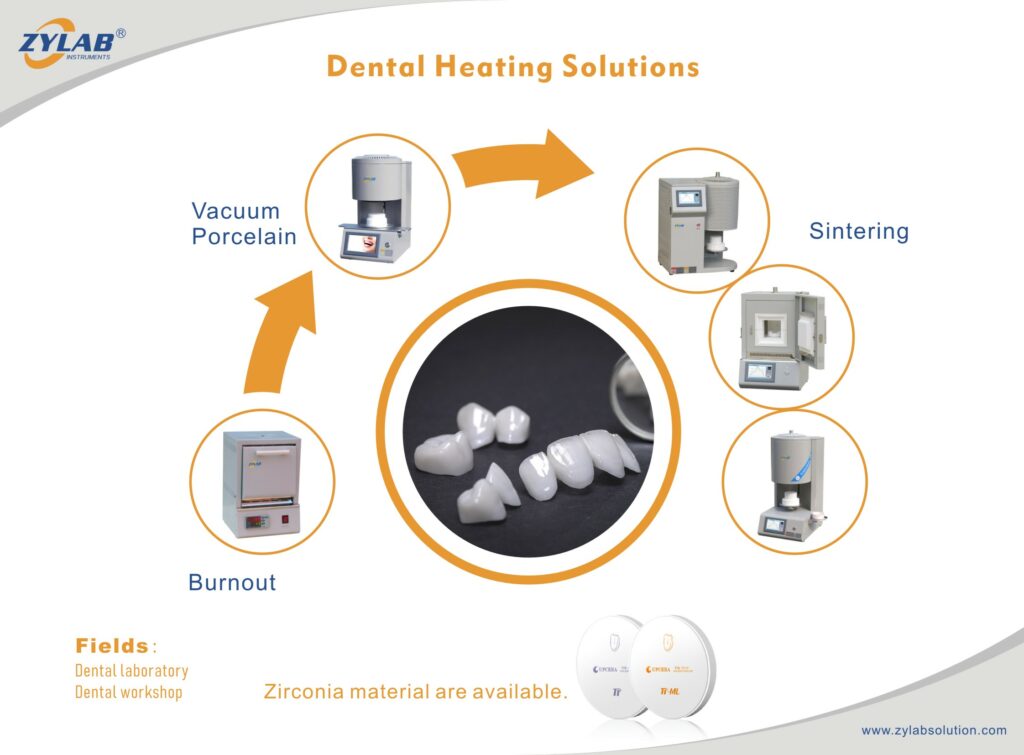

Applications:

Burnout

Vacuum Porcelain

Sintering

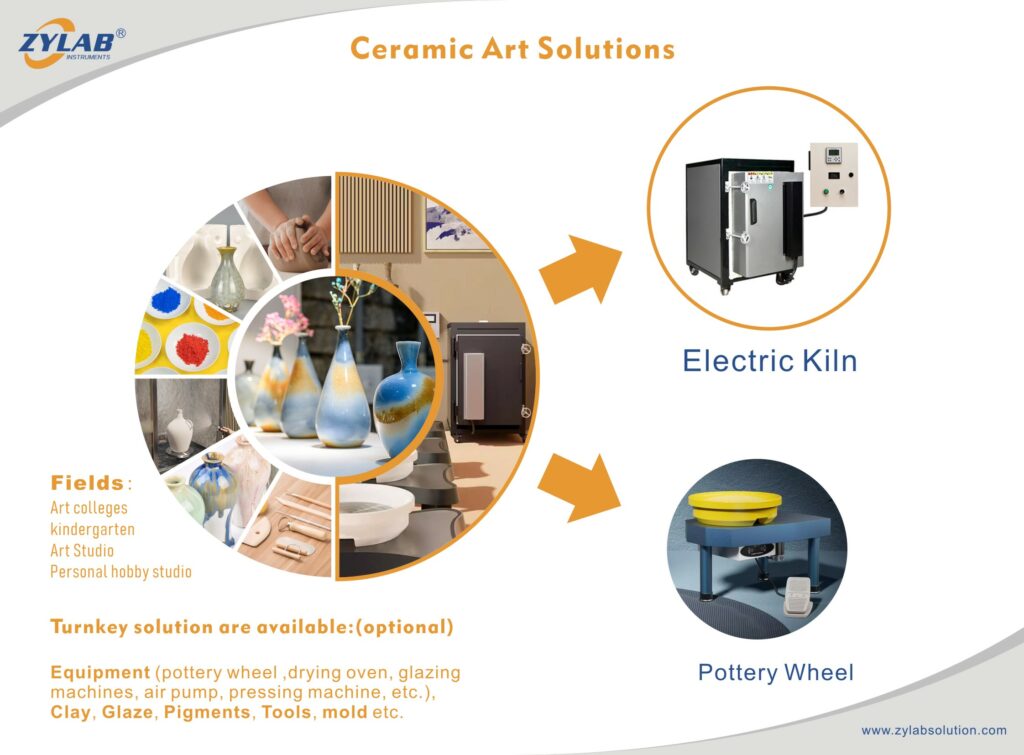

Turnkey solution are available:(optional)

1. Equipment( pottery kiln, pottery wheel, drying oven, glazing machine, air pump, pressing machine, etc )

2. Clay

3. Glaze

4. Pigments

5. Tools

6. Mold, etc

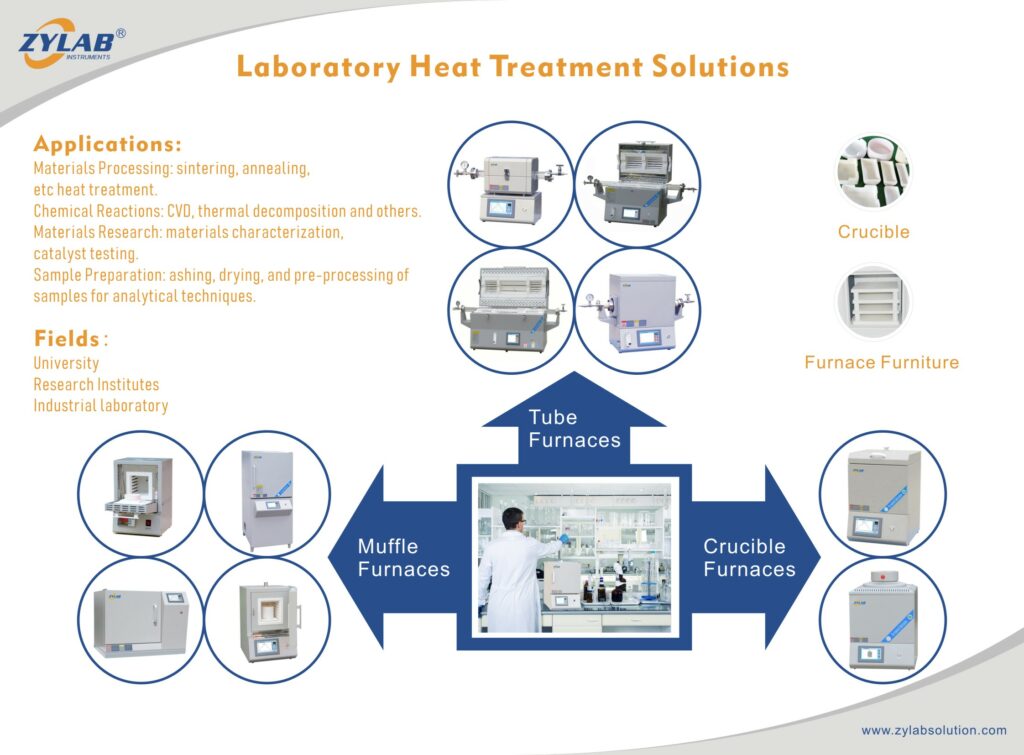

Materials Processing: sintering, annealing, etc heat treatment.

Chemical Reactions: CVD, thermal decomposition and others.

Materials Research: materials characterization,catalyst testing.

Sample Preparation: ashing, drying, and pre-processing of samples for analytical techniques.

.jpg)

A mini tube furnace is a compact and versatile high-temperature heating device commonly used in laboratories and small-scale industrial settings.

A laboratory tube furnace is comprises a tubular chamber where samples or materials are heated to high temperatures for processes such as annealing, sintering, chemical reactions, and materials research.

A horizontal tube furnace is a specialized heating device used for high-temperature applications in laboratories, research, and industry. Unlike traditional vertical tube furnaces, this type of furnace features a horizontal orientation, making it suitable for processes that require horizontal positioning of samples.