Table of Contents

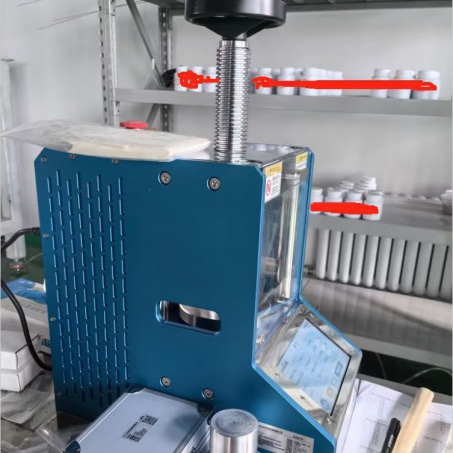

Proper maintenance is essential to ensure the stable performance, long service life, and safety of a tablet press machine. Regular inspection, lubrication, and cleaning not only help prevent equipment failure but also ensure consistent tablet quality.

This guide provides a detailed overview of the daily and periodic maintenance procedures for laboratory-scale tablet presses.

Hydraulic System Maintenance

The hydraulic system plays a crucial role in maintaining the pressing force and overall stability of the machine.

-

Oil Replacement:

Replace the hydraulic oil every 6–12 months under normal operating conditions. For machines used frequently or under heavy load, replace it every 3–6 months to maintain stable hydraulic pressure and avoid system wear. -

Inspection:

Regularly check the hydraulic system for oil leaks, abnormal noise, vibration, or overheating. Examine all seals, hoses, and fittings, and replace them immediately if any wear or damage is detected. Maintaining clean, leak-free hydraulics ensures consistent pressure and longer service life.

Lubrication

Lubrication is one of the most important aspects of tablet press maintenance. Proper lubrication ensures smooth mechanical motion, reduces friction and wear, and extends the lifespan of the equipment.

-

Lubrication Points:

Key moving parts such as the hydraulic cylinder, piston, and transmission components must be regularly lubricated to ensure stable and efficient operation. -

Lubrication Frequency:

Lubricate the machine at least once a week to maintain optimal performance and prevent metal-to-metal contact between moving parts. -

Lubrication Method:

Use the manual lubrication system on the press to apply oil to the designated points. Be mindful of the oil quantity—both insufficient and excessive lubrication can cause issues. Always use the manufacturer-specified lubricating oil for best results.

Mechanical and Electrical System Checks

To ensure the machine operates safely and efficiently, periodic inspection of the mechanical and electrical systems is necessary.

-

Mechanical Inspection:

Check the transmission system—including gears, belts, and chains—for proper alignment and tightness at least once a month. Adjust or replace worn components as needed. -

Electrical Inspection:

Inspect all electrical connections, switches, sensors, and control panels for proper function. Look for signs of overheating, loose wiring, or insulation damage, and address any issues promptly to avoid safety risks or machine malfunctions.

Environmental and Storage Requirements

The environment in which the tablet press is installed has a significant impact on its stability and lifespan.

-

Place the machine in a stable, vibration-free location to prevent misalignment or mechanical fatigue.

-

Avoid direct sunlight and radiation, which may affect the hydraulic oil and electrical components.

-

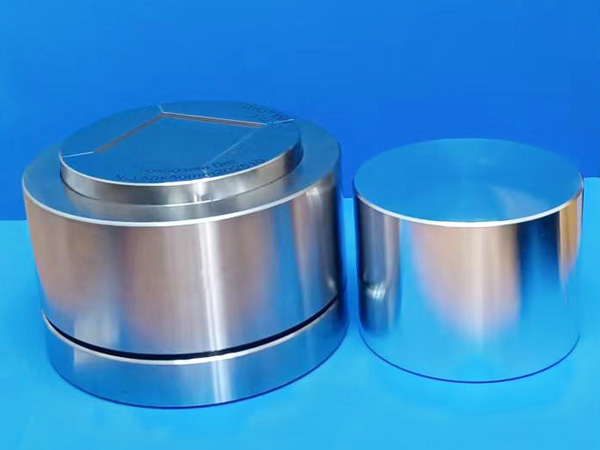

Maintain a dry, clean environment to protect molds and metallic parts from rust.

-

Prevent exposure to strong airflow, moisture, and dust, which may enter the press and affect precision or cleanliness.

Cleaning and Daily Operation

Cleanliness and proper handling are key to ensuring the reliability and accuracy of each pressing cycle.

-

Cleaning:

After each use, clean the machine thoroughly to remove any powder residues. This prevents cross-contamination and mechanical wear. -

Operator Safety:

Operators must be well-trained and fully understand the machine structure, operation, lubrication points, and safety protocols. Always wear protective gloves and safety glasses when operating or maintaining the machine.

Conclusion

Following a structured maintenance routine for your tablet press machine ensures long-term stability, consistent production quality, and operator safety. By regularly inspecting the hydraulic, mechanical, and electrical systems—and maintaining proper lubrication and cleanliness—you can minimize downtime, reduce repair costs, and extend the life of your equipment.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!