Table of Contents

Introduction

Following Part 1: Mechanical Milling Method, this second installment of the Powder Preparation Series focuses on chemical methods for producing powders. Unlike mechanical milling, which relies on physical forces, chemical methods leverage chemical reactions to synthesize powders with precise composition, controlled particle size, and uniform morphology.

Chemical powder production is widely used in ceramics, metallurgy, catalysts, battery materials, and nanomaterials, where purity, homogeneity, and particle size distribution are critical.

Overview of Chemical Powder Preparation Methods

1. Precipitation Method

Gaseous or dissolved precursors react to form solid precipitates, which are then washed, dried, and collected as powders.

Advantages: Fine particle size, high compositional uniformity, and scalable production.

Applications: Ceramic oxides, metal hydroxides, and catalyst precursors.

Equipment: Stirring reactors, magnetic stirrers, filtration or centrifugation units, drying ovens, optional ball mills or mortar grinders.

2. Sol-Gel Method

A solution (sol) undergoes hydrolysis and polycondensation to form a gel, which is then dried and calcined into powders.

Advantages: High purity, nanoscale particle size, and uniform composition.

Applications: Advanced ceramics, catalyst supports, and functional coatings.

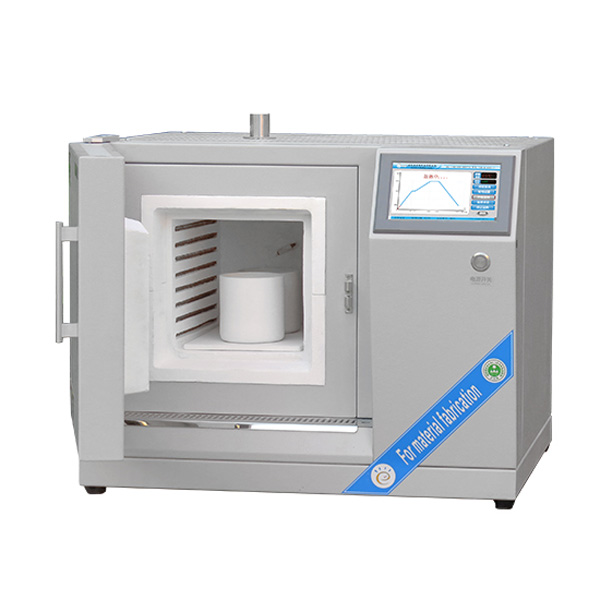

Equipment: Magnetic or mechanical stirrers, reaction vessels, drying ovens, high-temperature furnaces for calcination, optional grinding/milling equipment.

3. Co-precipitation Method

Multiple components precipitate simultaneously from a homogeneous solution, producing uniform mixed powders.

Advantages: Excellent compositional uniformity and suitable for multi-component powders.

Applications: Battery electrode materials, mixed oxide ceramics, and magnetic powders.

Equipment: Stirring reactors, titration devices, centrifuge or filtration systems, washing and drying equipment, optional ball mills.

4. Spray Pyrolysis

Atomized droplets of precursor solution decompose at high temperature to form fine powders.

Advantages: Uniform particle size and morphology, high purity, and spherical powders.

Applications: Functional ceramics, phosphors, and battery electrode powders.

Equipment: Atomizers or spray nozzles, high-temperature tube furnaces or reactors, gas flow control system, powder collection units.

5. Hydrothermal / Solvothermal Synthesis

Reactions occur under high-pressure and high-temperature conditions in aqueous or organic solvents, producing crystalline powders directly.

Advantages: Direct crystalline powder formation, controlled particle size and morphology, low agglomeration.

Applications: Nanomaterials, advanced ceramics, and functional composites.

Equipment: High-pressure autoclaves or reactors, heating and temperature control systems, optional stirring devices, washing and drying equipment.

6. Chemical Vapor Deposition (CVD) and Gas-Phase Methods

Gaseous precursors react or decompose to form solid powders.

Advantages: Ultra-pure powders, controlled morphology, and nanoscale sizes.

Applications: Carbon materials, ceramics, and high-tech composites.

Equipment: CVD reactors or high-temperature tube furnaces, gas supply and flow control systems, powder collection units, temperature control and monitoring systems, waste gas treatment systems.

Advantages of Chemical Methods

-

High Purity and Homogeneity – Ideal for advanced materials requiring controlled stoichiometry.

-

Particle Size Control – Easily produces submicron or nanoscale powders.

-

Tailored Morphology – Spherical, flake, or rod-like powders can be obtained.

-

Complex Compositions – Enables precise synthesis of mixed oxides or alloys.

-

Enhanced Reactivity – Fine, uniform powders improve sintering and chemical reactivity.

Applications of Chemically Produced Powders

-

Ceramics – Alumina, zirconia, and silicon carbide powders for high-performance applications.

-

Metallurgy – Powdered alloys and intermetallic compounds for powder metallurgy and additive manufacturing.

-

Nanomaterials – Nanopowders for electronics, optics, and coatings.

-

Battery Materials – Cathode and anode materials with uniform particle size distribution.

-

Catalysts – High surface area powders for chemical reactions and environmental applications.

Conclusion

Chemical powder production methods complement mechanical milling by providing precisely controlled, high-purity, and homogeneous powders. While they are generally more complex and costly, their ability to produce tailored powders for high-tech applications makes them indispensable in research and industry.

The combination of mechanical and chemical methods often yields optimal results, allowing materials scientists to design powders with both desired physical and chemical properties.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!