Table of Contents

Quenching and tempering, commonly known as “tempering after quenching” or “quench-temper treatment”, is a fundamental heat treatment process used to optimize the mechanical properties of steel.

This article explores what quenching and tempering is, its purpose, how it differs from simple quenching, and essential technical considerations for researchers and engineers.

What is Quenching and Tempering (QT)?

Quenching and tempering (QT) is a two-step heat treatment process:

-

Quenching – The steel is heated above its critical temperature (A3 for hypo-eutectoid steels, typically 800–900°C) and then rapidly cooled in water, oil, or another quenching medium. This produces a hard but brittle martensitic structure.

-

Tempering – The quenched steel is reheated to a temperature below the critical point (150–700°C) for a controlled period and then cooled, usually in air. Tempering reduces brittleness, relieves residual stresses, and adjusts mechanical properties to achieve a balance between hardness and toughness.

Purpose of Quenching and Tempering

The primary goal of QT is to produce steel with high hardness and sufficient toughness for industrial or research applications. Quenched steel alone is extremely hard (HRC 60–65) but brittle, prone to cracking under stress. Tempering modifies the martensite structure, relieving internal stresses and slightly reducing hardness while greatly improving toughness.

Key objectives include:

-

Stress relief – Reduces residual stresses from quenching.

-

Hardness control – Achieves target hardness for machining, wear resistance, or structural performance.

-

Toughness enhancement – Prevents brittle fracture in service.

-

Dimensional stability – Critical for precision components such as gears, shafts, dies, and molds.

-

Microstructure optimization – Fine carbide precipitation improves long-term material performance.

Advanced Considerations for Researchers

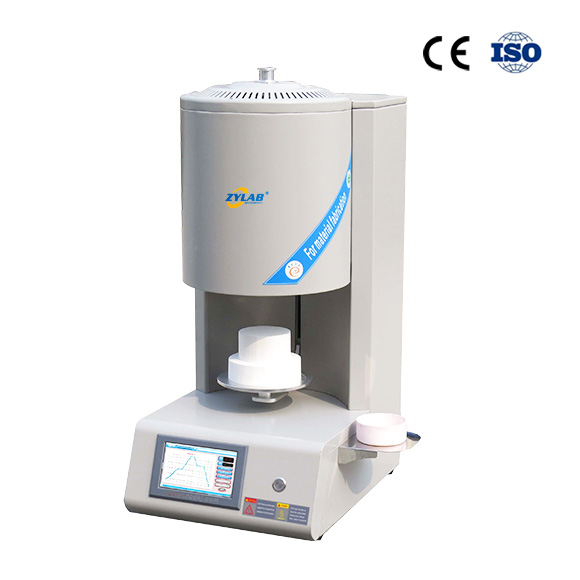

For research and industrial applications, the quenching and tempering (QT) process can be precisely controlled using batch-type box furnaces, which are ideal for small to medium batch production or research experiments.

Batch-Type Box Furnace (Intermittent Furnace)

-

Definition: A furnace where steel workpieces are loaded in batches, heated to quenching temperature, and then tempered, all within the same chamber.

-

Bottom Loading Furnace Advantage: Our Bottom Loading Furnace allows safe loading and unloading even at temperatures up to 1300°C, providing excellent convenience and safety for research operations.

-

Temperature Uniformity: Modern batch furnaces maintain a uniform temperature across the chamber, typically within ±1°C, ensuring consistent mechanical properties.

-

Application: Ideal for precision components, tooling, structural steel, and high-alloy steels used in R&D and small batch production.

Alloy Steels

Alloying elements like Cr, Mo, V, and Ni increase tempering resistance, allowing higher tempering temperatures without excessive hardness loss. This is essential for high-strength steels in aerospace, automotive, and tooling applications.

Multiple Tempering

Double or triple tempering cycles are used for high-carbon or high-alloy steels to further reduce brittleness and stabilize hardness.

Tempering Embrittlement

Prolonged tempering in the 350–450°C range may cause “temper embrittlement” in certain steels, characterized by decreased impact toughness.

Practical Example of Quenching and Tempering

Medium-carbon steel (0.4% C, 0.5% Cr, 0.2% Mo):

| Step | Temperature (°C) | Duration | Hardness (HRC) | Toughness (J, Charpy V-notch) |

|---|---|---|---|---|

| Quenching | 840 | Water | 62 | 10 |

| Tempering | 400 | 60 min | 52 | 30 |

| Tempering | 550 | 60 min | 45 | 60 |

This shows how tempering temperature directly affects hardness and toughness.

Summary

Quenching and tempering is a core heat treatment process that combines high hardness with improved toughness. By controlling quenching and tempering parameters—temperature, time, and alloy composition—researchers and engineers can optimize steel for structural, tooling, or specialized applications.

Understanding QT is essential for advanced materials engineering and precise mechanical performance design.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!