Table of Contents

Introduction

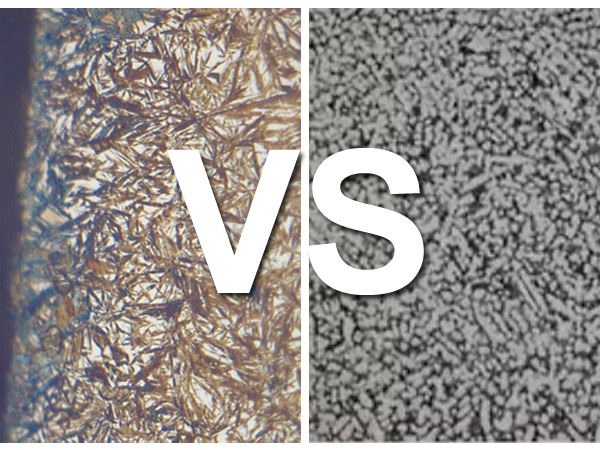

Carburizing and nitriding are two important thermochemical heat treatment processes used to improve the surface properties of metals, particularly steels. While conventional heat treatment methods like annealing, normalizing, and quenching alter the bulk properties of a material, carburizing and nitriding focus on the surface layer, creating a hard, wear-resistant shell while maintaining a tough and ductile core.

What is Carburizing?

Carburizing is the process of diffusing carbon atoms into the surface of low-carbon steel at elevated temperatures, typically between 850–950°C. The goal is to enrich the surface with carbon so that, after quenching, the steel develops a hard martensitic case with high wear resistance.

Types of Carburizing

-

Gas Carburizing – Performed in a furnace atmosphere enriched with gases such as methane or propane.

-

Liquid Carburizing – Uses molten salt baths containing carbonaceous compounds.

-

Vacuum Carburizing (Low-Pressure Carburizing, LPC) – A modern technique performed under vacuum with precise control of carbon potential, ideal for clean and distortion-sensitive parts.

-

Plasma Carburizing – Uses plasma discharge to activate carbon transfer, offering high efficiency and reduced environmental impact.

Benefits of Carburizing

-

Increases surface hardness and wear resistance.

-

Improves fatigue strength due to compressive residual stresses.

-

Maintains a tough, impact-resistant core, ideal for gears, bearings, and shafts.

What is Nitriding?

Nitriding is the process of diffusing nitrogen into the surface of steel or other alloys at temperatures between 500–550°C. Unlike carburizing, nitriding does not require subsequent quenching because hard nitrides form directly during the treatment.

Types of Nitriding

-

Gas Nitriding – Performed in an ammonia atmosphere, where nitrogen atoms diffuse into the steel.

-

Plasma (Ion) Nitriding – Uses glow discharge plasma to introduce nitrogen; offers excellent control over case depth and hardness.

-

Salt Bath Nitriding – Employs nitrogen-rich salt baths; less common today due to environmental regulations.

Benefits of Nitriding

-

Produces extremely hard, wear-resistant surfaces.

-

Provides excellent fatigue resistance without quenching.

-

Offers corrosion resistance due to nitride layer formation.

-

Minimal distortion because of the lower processing temperature.

Key Differences Between Carburizing and Nitriding

| Aspect | Carburizing | Nitriding |

|---|

| Diffused element | Carbon | Nitrogen |

| Typical temperature | 850–950°C | 500–550°C |

| Quenching required | Yes, for hardening | No, nitrides form directly |

| Distortion risk | Higher (due to quenching) | Lower (no quenching) |

| Surface hardness | High, depending on quench and temper | Very high, due to nitride formation |

| Case depth | Deeper (typically 0.5-2.5 mm) | Shallower (typically 0.1-0.6 mm) |

| Applications | Gears, shafts, bearings | Tools, dies, aerospace components |

Applications in Research and Industry

-

Carburizing is widely used for automotive gears, camshafts, and bearings, where both wear resistance and core toughness are critical.

-

Nitriding is preferred for tool steels, aerospace parts, and precision components, where dimensional stability and surface hardness are vital.

In modern research, both processes are studied in combination with advanced furnace technologies such as vacuum furnaces, controlled atmosphere furnaces, and plasma systems. Researchers often explore the influence of alloy composition, process parameters, and post-treatments to optimize performance.

Conclusion

Carburizing and nitriding remain essential techniques in materials engineering and heat treatment research. By tailoring surface hardness, fatigue resistance, and wear properties, these processes enable steels and alloys to perform under demanding industrial conditions.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!