Table of Contents

Quenching is a key heat treatment process designed to achieve extreme hardness through rapid cooling. In this article, we explore the principles and techniques of quenching, revealing how speed and precision create high-performance materials.

Definition of Quenching

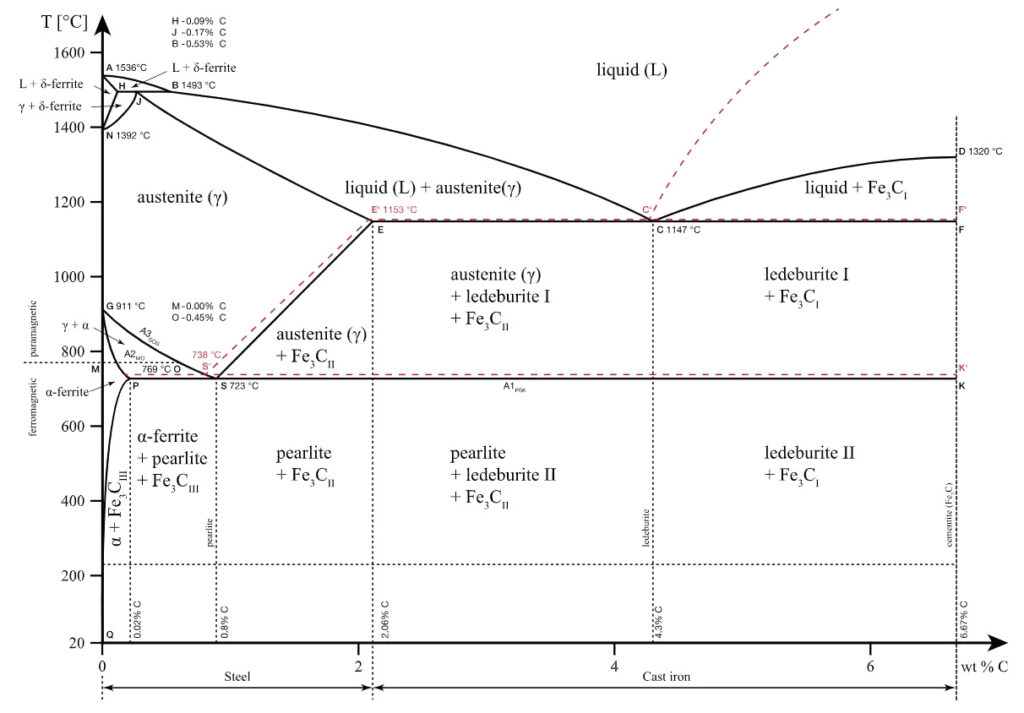

Quenching is a heat treatment process in which a metal—most commonly steel—is heated to a temperature above its critical transformation point (45# steel 820–860 °C, High-carbon tool steel 760–800 °C), held until the structure becomes austenitic, and then rapidly cooled using a quenching medium such as water, oil, polymer solution, or gas.

The sudden cooling transforms the microstructure of steel from austenite into martensite, which is extremely hard but also brittle.

Purpose of Quenching

The primary goal of quenching is to increase hardness and strength. Specific objectives include:

-

Achieving high surface hardness for wear resistance.

-

Improving tensile strength and fatigue resistance.

-

Preparing the steel for further tempering, which adjusts hardness and toughness balance.

-

Stabilizing dimensions for precision parts (e.g., bearings, tools, gears).

Example: After quenching, medium-carbon steel (0.45% C) can reach hardness levels of HRC 55–65, depending on cooling rate and medium.

Comparison: Quenching vs. Normalizing vs. Annealing

| Feature | Annealing | Normalizing | Quenching |

|---|---|---|---|

| Heating Temp. | 30–50°C above Ac₃ (or Ac₁ for hypo/hyper eutectoid steels) | 30–50°C above Ac₃ | 30–50°C above Ac₃ |

| Cooling Method | Slow cooling in furnace | Air cooling | Rapid cooling in water, oil, or gas |

| Resulting Structure | Coarse pearlite + ferrite | Fine pearlite | Martensite (hard, brittle) |

| Hardness | Low | Medium | Very high |

| Ductility/Toughness | High | Medium | Low (before tempering) |

| Applications | Stress relief, machining | Strength balance | High wear resistance, cutting tools |

Additional Note:

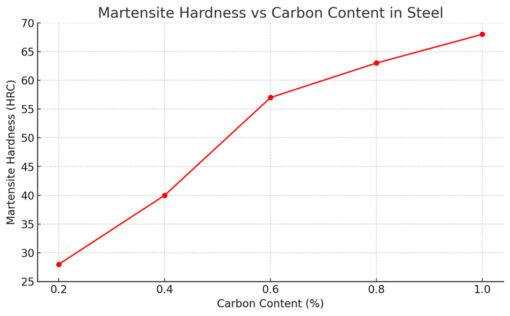

The hardness of martensite increases as the carbon content in steel rises.

-

At 0.2% C, quenched martensite has a hardness of about HRC 25–30.

-

At 0.6% C, hardness reaches around HRC 55–60.

-

At 1.0% C, it can exceed HRC 65, but the steel becomes very brittle and requires tempering.

Common Quenching Media

The choice of quenching medium determines cooling rate, hardness achieved, and risk of cracking or distortion.

-

Water

-

Very fast cooling.

-

Produces maximum hardness.

-

High risk of cracking and distortion.

-

Used for plain carbon steels.

-

-

Brine (Salt Water)

-

Even faster than water due to reduced vapor blanket.

-

Higher risk of cracking.

-

Rarely used today for delicate parts.

-

-

Oil

-

Moderate cooling rate.

-

Reduces risk of cracking and warping.

-

Common for alloy steels and precision tools.

-

-

Polymer Solutions

-

Adjustable cooling rate by concentration.

-

Combines advantages of water and oil.

-

Environmentally friendly.

-

-

Gas Quenching (Nitrogen, Helium, Argon)

-

Slower cooling, used in vacuum furnaces.

-

Minimizes oxidation and distortion.

-

Preferred for aerospace and high-precision components.

-

Quenching Applications

-

Tool and Die Manufacturing: Increases hardness and wear resistance of cutting tools and dies.

-

Automotive Components: Enhances strength and fatigue resistance of crankshafts, gears, and bearings.

-

Aerospace Materials: Rapid cooling improves strength and toughness of alloys.

-

Wear-Resistant Parts: Boosts surface hardness of pump shafts, gears, and mold cores.

-

Additive Manufacturing: Refines microstructure and mechanical properties of metal 3D printed parts.

Quenching Furnaces

-

Liquid Quench Furnaces: Equipped with water, oil, or polymer tanks for uniform cooling.

-

Salt Bath Furnaces: Provide high-temperature, rapid, and uniform cooling for tool and high-alloy steels.

- Gas Quench Furnaces: Use nitrogen or argon for fast cooling of sensitive alloys.

Conclusion

Quenching is a critical step in the heat treatment of steel, providing maximum hardness and strength but requiring careful control of medium, temperature, and subsequent tempering to avoid brittleness.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!