Table of Contents

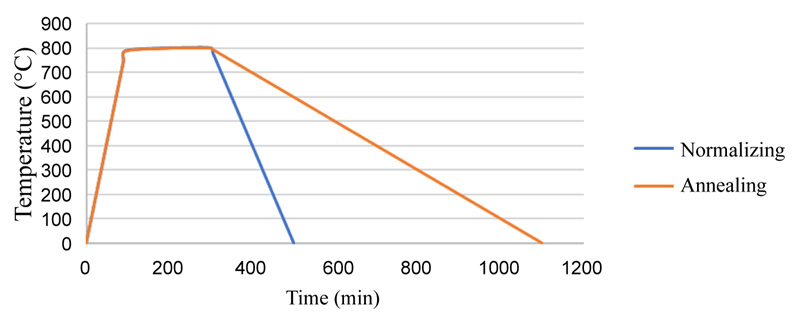

Normalizing is another essential heat treatment process used in metallurgy and materials engineering. In this article, we continue our Heat Treatment Series by explaining the definition, purpose, and unique features of normalizing, while also comparing it to annealing.

What is Normalizing?

Normalizing is a heat treatment process in which steel or alloy is:

-

Heated above the AC3 (or ACm for alloy steels) temperature, typically 30–50°C higher.

-

For carbon steels: usually 850–950°C.

-

-

Held (soaked) at this temperature long enough for complete transformation into austenite.

-

Cooled in still air at room temperature instead of furnace cooling.

This controlled heating and air cooling process produces a refined grain structure, improving both mechanical properties and machinability.

Key Parameters of Normalizing

| Parameter | Typical Range | Notes |

|---|---|---|

| Heating temperature | AC3 + 30–50°C (850–950°C for medium carbon steel) | Higher than annealing |

| Holding time | 1–2 hours depending on thickness | Ensures complete austenitization |

| Cooling method | Air cooling (1–10°C/s) | Faster than annealing |

Purpose of Normalizing

Normalizing offers several benefits:

-

Refines Grain Structure – Produces finer pearlite and ferrite grains compared to annealing.

-

Improves Mechanical Properties – Increases hardness (typically 160–220 HV for steels) and strength while maintaining good ductility.

-

Enhances Machinability – Provides a balance between softness (for machining) and strength.

-

Homogenizes Microstructure – Removes segregation in castings or forgings.

-

Prepares for Further Heat Treatment – Creates a stable structure before quenching or carburizing.

Comparison: Normalizing vs. Annealing

| Feature | Annealing | Normalizing |

|---|---|---|

| Heating temperature | AC3 + 20–30°C (e.g., 750–830°C) | AC3 + 30–50°C (e.g., 850–950°C) |

| Cooling method | Slow furnace cooling (10–50°C/hour) | Air cooling (1–10°C/s) |

| Microstructure | Coarse pearlite + ferrite | Fine pearlite + ferrite |

| Hardness | Lower (150–180 HV) | Higher (160–220 HV) |

| Purpose | Softening, stress relief, ductility | Refinement, strength, balanced machinability |

Choosing Between Annealing and Normalizing

-

Choose Annealing when:

-

High ductility is required

-

Maximum softness is needed for forming or machining

-

Stress relief after cold working is the main goal

-

-

Choose Normalizing when:

-

Strength and hardness are more important than softness

-

Fine, uniform grain structure is desired

-

Preparing castings or forgings for further heat treatment

-

In practice:

-

A steel gear blank may be normalized (for strength and fine grain) before quenching.

-

A sheet metal product may be annealed (for softness and easy forming).

Critical Temperatures in Normalizing

Understanding critical temperatures is essential for controlling the normalizing process:

| Symbol | Temperature (Approx.) | Description |

|---|---|---|

| AC1 | ~727°C | Pearlite begins to transform into austenite |

| AC3 | 770–910°C (depends on carbon content) | Ferrite fully transforms into austenite |

| ACm | 1100–1140°C (for high-alloy steels) | Cementite fully dissolves into austenite |

Applications of Normalizing

-

Castings and Forgings – Removes segregation, refines microstructure

-

Railway Wheels – Improves toughness and wear resistance

-

Automotive Components – Shafts, gears, and connecting rods for balanced strength and machinability

-

Tool Steels – Prepares for hardening and further heat treatment

-

Structural Steel Products – Ensures uniform mechanical properties before fabrication

Types of Furnaces for Normalizing

| Furnace Type | Features | Typical Use |

|---|

| Box Furnace (Batch Furnace) | Simple chamber, batch heating, flexible control | Laboratory, small-scale production |

| Bottom Loading Furnace | Cylindrical chamber with uniform heating, automatic lift, and safe operation | Forgings, gears, heavy-duty parts |

| Gas/Atmosphere-Controlled Furnace | Protective gas atmosphere, clean surface | Alloy steels, stainless steels |

Conclusion

Normalizing is a powerful heat treatment method that provides a balance between strength, hardness, and machinability by refining the grain structure of steel. Compared to annealing, it produces a stronger, harder material with finer microstructure, making it ideal for preparing components for further heat treatment or heavy-duty applications.

Get In Touch

Fill out the form below — free quote and professional suggestion will be sent for reference very soon!