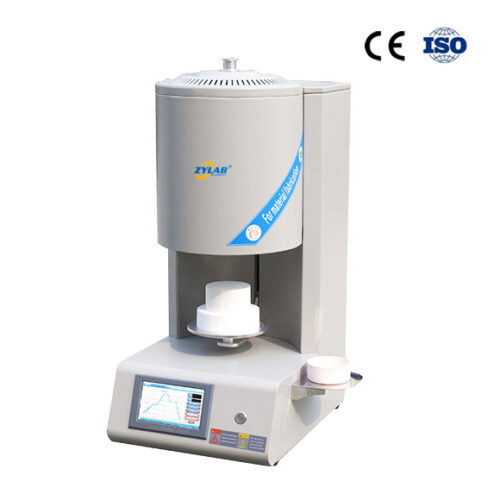

ZYLAB 80L Top Loading Pottery Kiln with Full Ring Firing

Introduction

A large-capacity, top-loading electric kiln engineered for high-temperature ceramic firing. Featuring full-ring heating, smart control, and durable construction, the ZYLAB 80L kiln is ideal for studios, schools, and ceramic workshops requiring consistent and efficient firing results.

Key Features

-

80L Firing Chamber

Spacious chamber allows multiple pieces to be fired in a single batch — for example, up to 85 cups measuring 7 cm in diameter and 10 cm in height can be accommodated at once. With an internal height of 59.5 cm — ideal for medium to large-scale creations. -

Full Ring Firing Design

Advanced 360° ring-shaped heating system ensures even temperature distribution, reducing hot spots and improving firing consistency. -

Compact, Top-Loading Structure

Space-saving top-loading design with a fully circular inner chamber allows easy loading/unloading while maximizing internal space. -

Smart Control System

Custom-developed intelligent controller with visual menu interface and preset programs. Supports one-touch operation for multiple firing modes. -

Concealed Thermocouple Placement

Integrated hidden thermocouple enhances space efficiency and prolongs temperature sensor lifespan. -

9.5cm Thick Mortise-and-Tenon Lid

Traditional mortise-and-tenon construction with reinforced insulation for superior heat retention and energy savings. - Lid Hover Function

When opened, the lid can stay suspended at multiple angles without falling, making it labor-saving and easy to operate. -

High-Temperature Hydrogen-Annealed Heating Elements

Durable and oxidation-resistant heater wires ensure long-term stable performance in high-temperature ceramic applications. -

Dual Language Interface

User-friendly bilingual (English/Chinese) touchscreen makes it easy to operate for both domestic and international users. -

Insulated rubber swivel casters

Make moving and handling easier, offering greater convenience for home use.

Applications of 80L Top Loading Pottery Kiln

-

Ceramic Art Studios

-

Pottery Teaching Labs

-

Home Pottery Workshops

-

Educational Institutions & Art Schools

Technical Specifications of 80L Top Loading Pottery Kiln

| Model | RK-80 |

| Chamber Volume | 80L (0.08 m³) |

| Power Rating | 8.8 kW |

| Voltage | AC 220V / AC 380V |

| Internal Dimensions | Ø420 mm × H595 mm |

| External Dimensions | Height: 965 mm |

| Diameter: 650 mm (855 mm with handles) | |

| Shelf Size | Ø350 mm round shelf plate |

| Weight | Net: ~163 kg |

| Gross: ~217 kg (incl. packaging) | |

| Max Temperature | 1300°C |

| Working Temperature | Up to 1280°C for continuous operation |

| Heating Rate | 7°C/min |

| Heating Element | Ø14 mm hydrogen-annealed alloy wires |

| Insulation Thickness | Side: 120 mm |

| Bottom: 130 mm | |

| Top: 95 mm | |

| Viewing/Exhaust Port | Ø18 mm |

| Power Consumption per Firing | ~54 kWh (empty chamber test) |

| Insulation Resistance | 0.6–2 MΩ |

| Forward Pressure Resistance | >500 kPa |

| Reverse Voltage Resistance | >2 MPa |

| Signal Feedback | >0.5 s/cycle |

| Thermal Conductivity (Curved Surface) | ≤0.2 W/m³ |

Standard Accessories

Our 80L Top Loading Pottery Kiln comes with a complete set of standard accessories to meet your basic pottery firing needs. With these accessories, you can start firing your ceramics immediately after receiving the kiln.

Standard Accessories Include:

-

Shelves:

-

4 × 35 cm round kiln shelves

-

4 × half-round kiln shelves

-

-

Kiln Posts:

-

12 × 1 cm posts

-

12 × 5 cm posts

-

12 × 10 cm posts

-

-

Safety Equipment:

-

1 pair of high-temperature gloves

-

These accessories allow flexible stacking and arrangement of your pottery pieces, ensuring even heating and optimal firing results.

Cooling Tips

-

Above 1000°C: Open both ventilation holes to accelerate heat dissipation.

-

Around 300°C: Slightly crack open the kiln lid (5–10 cm gap) for controlled cooling.

-

Below 200°C: Turn off the power and safely remove your ceramic artworks.

Installation Requirements

-

63A circuit breaker (without residual current device).

-

Use copper core wire with a cross-sectional area ≥ 10 mm² (national standard compliant).

Turnkey solution are available:(optional)

Equipment (pottery wheel ,drying oven, glazing machines, air pump, pressing machine, etc.)

(Details, pls contact with our expert)