ZYLAB Laboratory Small Filter Centrifuge

Overview

The ZYLAB T300 Small Filter Centrifuge is specially designed for laboratory-scale and mobile experimental use. With a 10L working volume, it adopts a flat-plate top-opening design equipped with a feed pipe, washing pipe, and viewing window on the lid, allowing online feeding and washing (can be directly connected to a reactor if required).

The centrifuge is mounted on a movable trolley for flexible operation in different laboratory environments. The control cabinet enables speed adjustment, timed stop, and energy braking functions. An explosion-proof control cabinet is also available as an option for full system explosion protection.

The base is reinforced with heavy-duty damping pads and lockable wheels, providing excellent stability and vibration reduction. The entire structure is made of stainless steel, suitable for handling materials with strong odors or those requiring sealed operation.

Working Principle

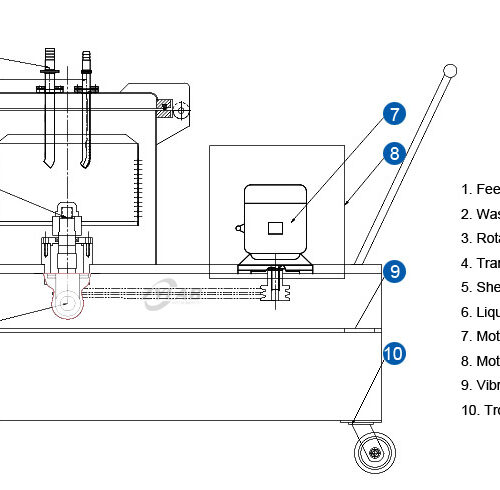

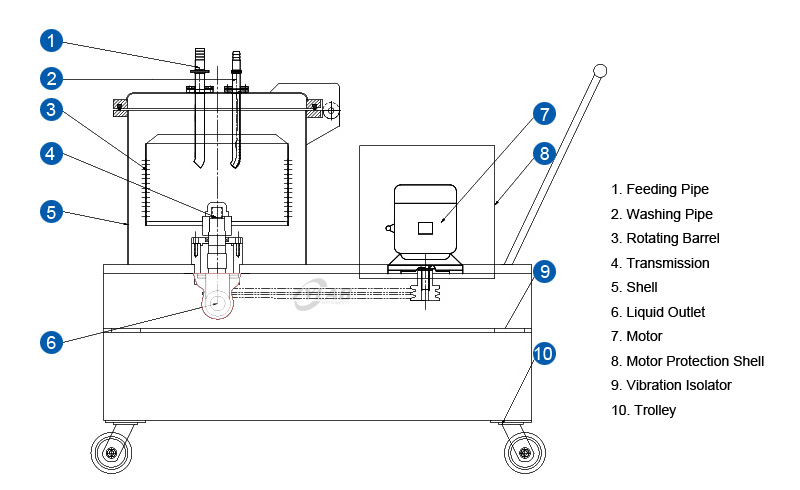

The centrifuge consists of a housing, drum, base, damping pads, and transmission components. The drum rotation is driven by the motor pulley and V-belt transmission system.

For materials with high solid content, feeding is done before starting; for high liquid content, the centrifuge is started first and then fed. Under centrifugal force, the solid particles are evenly distributed along the drum wall. The liquid phase passes through the filter cloth and discharge holes, while the solid phase remains inside the drum.

Once separation is complete, power is cut off and energy braking or a mechanical braking system stops the drum. The separated solids are manually discharged from the top after the centrifuge stops completely.

Main Features

-

Multiple Material Options: Available in 304 stainless steel, 316L stainless steel, titanium alloy, or plastic-lined construction to suit different corrosion resistance requirements.

-

Reliable Braking System: Equipped with an energy consumption braking unit and braking resistor, ensuring quick and safe stopping performance.

-

Uniform Feeding: The dedicated feed pipe design ensures even distribution of materials for smooth and stable operation.

-

Convenient Top-Opening Design: The spring-assisted hinged lid with three quick-locking buckles allows easy, safe, and reliable operation. It also provides excellent sealing performance for enclosed operation.

-

GMP-Compliant Design: Designed specifically for laboratory environments, featuring compact structure, lightweight construction, and fast operation, compliant with GMP standards.

-

Quality Standards: Manufactured in accordance with JB/T10769.2-2007 and the ISO9001:2000 quality management system.

Structure Diagram

Technical Specifications

| Model | Drum Diameter (mm) | Speed (r/min) | Separation Factor | Working Volume (L) | Load Limit (kg) | Motor Power (kW) | Weight (kg) | Dimension (L×W×H, mm) |

| T200 | 200 | 3000 | 1007 | 2 | 3 | 0.55 | 75/90 | 600 × 400 × 1000 |

| T300 | 300 | 2800 | 1316 | 10 | 12 | 1.1 | 120/160 | 850 × 500 × 1000 |

| T450 | 450 | 1900 | 910 | 20 | 30 | 1.5 | 280/360 | 1000 × 700 × 1100 |

Standard Configurations

-

Material: 316L stainless steel

-

Filter Bag: Polypropylene (PP), Polyester (PET), or Nylon — mesh size optional

-

Motor: Standard motor (explosion-proof motor optional)

-

Control Cabinet: Integrated control cabinet with speed and time control

-

Structure: Mounted on a mobile trolley for easy movement

Typical Applications

-

Laboratory and pilot-scale solid-liquid separation

-

Chemical and pharmaceutical intermediate filtration

-

Catalyst recovery and product washing

-

Extraction and purification experiments

-

Materials requiring odor containment and sealed operation