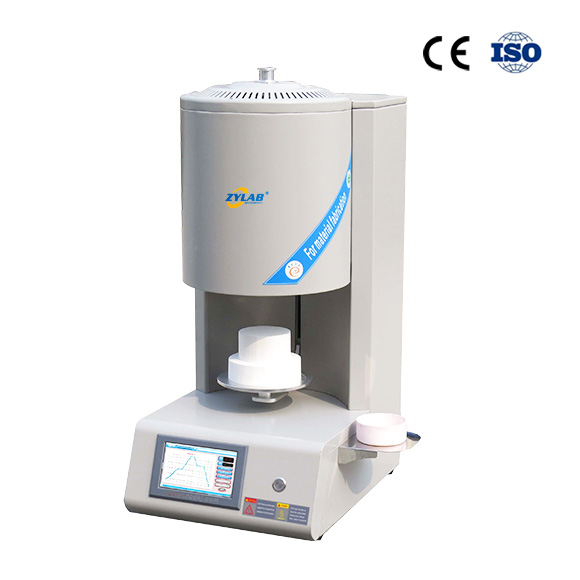

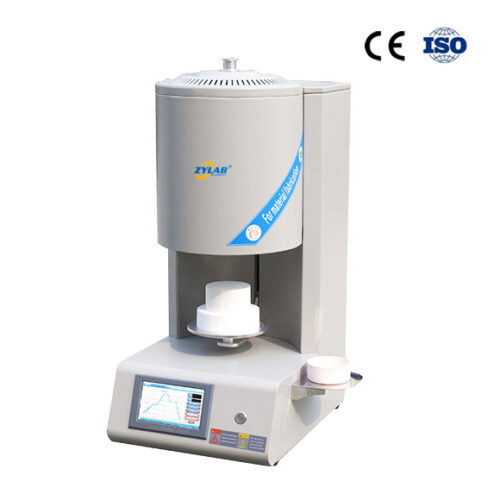

ZYLAB Lab Furnace with Safe Door Opening at High Temperature

Introduction

The ZYLAB 1300°C Lab Furnace is a compact, practical, and high-performance furnace designed for modern laboratory heat treatment applications. With its automatic bottom loading and lifting system, this model greatly simplifies the sample loading process while ensuring maximum operator safety at high temperatures. The furnace chamber adopts a round heating design with heating elements distributed on all sides, providing an exceptionally uniform temperature field.

Its advanced 7-inch touch screen controller allows for easy operation, real-time process monitoring, and storage of multiple temperature programs—ideal for laboratories and research institutes that frequently conduct different experimental procedures.

Main Features

-

Max. Temperature: 1500°C (Working Temperature RT–1450°C) – Suitable for medium-to-high temperature applications.

-

Safe Door Opening & Automatic Lifting Structure – Bottom-loading design with silent bilateral lifting system for stable and safe operation.

-

7” Color Touch Screen Controller – Intelligent control with clear interface, easy operation, and process storage.

-

Programmable Control – Up to 30 programmable segments for flexible heat treatment cycles.

-

High-Quality Furnace Chamber – Ceramic fiber insulation ensures fast heating, energy efficiency, and reduced heat loss.

-

Superior Heating Elements – High-quality SiC heating elements with excellent acid and corrosion resistance, providing long service life.

-

Uniform Temperature Distribution – Ring-distributed heating elements ensure a constant temperature field for better results.

-

Efficient Exhaust Solution – Specially designed exhaust port (latex hole) allows safe removal of gases during material sintering.

Technical Parameters

| Model | B1500-12 |

|

Furnace structure |

•1600 type high purity ceramic fibre insulation (energy saving 40% and weight lighter about 30% than old furnace); • Double layers steel casing with fan cooling, to ensure the surface of furnace below 50.C. |

| Chamber size

(working space) |

Dia100*150mm |

| Max. temperature | 1500 ℃(<1hours) |

| Working temperature | RT-1450 ℃(continuing) |

| Intelligent Touch Screen

Temperature controller |

•PID automatic control and auto-tune function. •30 programmable segments for precise control. •Built in protection for over-heated and broken thermal couple, and leakage. • Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation.•.Can store sintering programs to avoid the trouble caused by repeated settings of different experimental processes. |

| Heating rate | 0-20 ℃ /min(Suggest: 10°C/min) |

| Thermocouple | S type |

| Temperature accuracy | +/- 1 ℃ |

| Heating element | High-purity sic heating element with excellent acid and corrosion resistance |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) |

| Max. Power | 1.5 Kw |

| Dimension | 400(W)*870(H)*540(D)mm |

| Quantity / Net weight | 1set / 55kgs |

| Warranty | 18 months(not including consumable parts, such as heating elements, thermocouple, etc), lifetime support. |

| Certificate | CE, ISO9001 |

Applications

-

Ceramic Sintering – Powder materials, ceramic crucibles, and lab-scale ceramics

-

Material Research – Thermal analysis, phase transformation, glass and metal sample processing

-

University & Institute Laboratories – Teaching, experimental studies, and sample preparation

-

Industrial Applications – Small-batch production, annealing, additive manufacturing post-treatment

Why Choose ZYLAB?

-

Safe & Practical Design – Automatic lifting and safe door opening even at high temperatures

-

High Temperature Uniformity – Optimized heating element distribution for reliable results

-

Customizable Options – Gas inlet, exhaust treatment, chamber size available on request

-

Trusted by Global Clients – Widely supplied to research institutions and industrial R&D labs worldwide

For More Bottom Loading Furnaces / Bell Furnaces

Please visit our website [Bottom Loading Furnaces Collection]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]