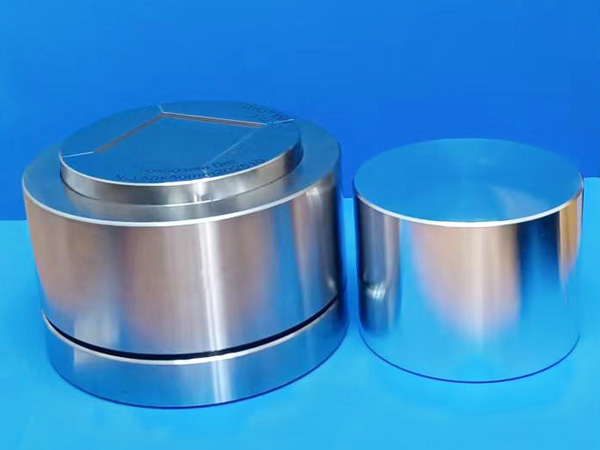

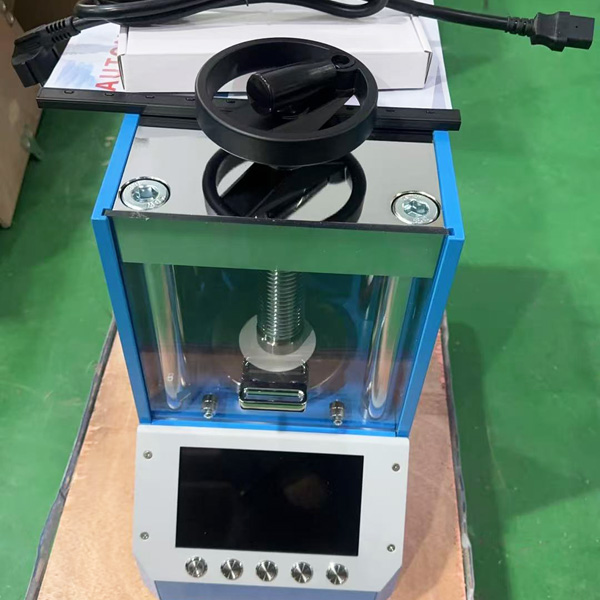

Case Study: Supplying Half Round Boat Crucibles with Covers to the University of Eastern Piedmont (UPO), Italy

At ZYLAB, we are committed to supporting global research institutions with high-quality laboratory ceramics and thermal processing solutions. Recently, we had the opportunity to collaborate with the Department of Science and Technological Innovation at the University of Eastern Piedmont (UPO), Italy, providing them with our Half Round Boat Crucibles with Covers for their materials research projects.