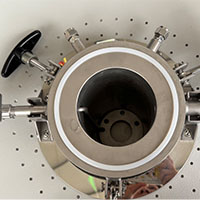

ZYLAB Vacuum Molten Salt Electroplating Furnace

Introduction

The Vacuum Molten Salt Electroplating Furnace is a specialized system designed for metal deposition processes using molten salt electrolytes under vacuum conditions. By integrating vacuum technology with high-temperature molten salt electroplating, the furnace enables the creation of high-purity, high-performance metallic coatings in a precisely controlled environment.

This advanced equipment is widely used in industries such as aerospace, electronics, new materials, and energy technologies—especially for applications requiring corrosion resistance, wear resistance, and excellent electrical conductivity.

Key Features

Vacuum Chamber Design

-

High-Purity Coatings: The vacuum environment removes air and impurities, preventing oxidation and ensuring high-purity metal deposition.

-

Contamination-Free Process: Minimizes the introduction of external pollutants, improving coating uniformity and reliability.

Molten Salt Electrolyte System

-

High-Temperature Operation: Capable of operating from 400°C to 800°C, allowing for electroplating of refractory metals such as titanium and zirconium.

-

Uniform Current Distribution: Molten salt provides excellent conductivity and thermal stability, enabling uniform and dense metal layers.

Precise Temperature Control

-

PID Intelligent Control: Maintains temperature stability within ±1°C for consistent plating results.

-

Programmable Heating Profiles: Supports multi-step ramping and holding segments to meet complex process requirements.

Advanced Automation

-

Touchscreen Interface: Intuitive operation with parameter input, process control, and real-time display.

-

Data Logging & Analysis: Automatically records critical parameters for quality assurance and process optimization.

Robust Safety Measures

-

Overtemperature Protection: Built-in sensors trigger automatic shutdown in case of overheating.

-

Emergency Stop Function: Ensures operator safety during abnormal conditions.

-

Optional Gas Leak Detection: For applications requiring controlled atmospheres, enhancing lab and operator safety.

Versatile Applications

-

Multiple Coating Materials: Suitable for plating gold, silver, copper, nickel, and various rare metals and alloys.

-

Functional Coatings: Enables high-performance coatings such as anti-corrosion, wear-resistant, and oxidation-resistant films.

Technical Specifications of Vacuum Molten Salt Electroplating Furnace

| Product Model | G1200-10 | |

| Power Supply | 220V, 50Hz | |

| Rated Power | 3 kW | |

| Temperature Control Accuracy | ±1°C | |

| Heating Element | Alloy heating wire | |

| Temperature Control Thermocouple | K-type, φ2×350 mm | |

| Measuring Thermocouple | K-type, right-angle, φ8×100 mm + 450 mm (aviation connector) | |

| Maximum Temperature | 1150°C | |

| Continuous Operating Temp. | 1100°C | |

| Recommended Heating Rate | ≤10°C/min | |

| Reactor Chamber Size | Φ120×368 mm (Effective sample space: approx. Φ78×160 mm) | |

| Furnace Chamber Size | Φ150×200 mm | |

| Flow Meter Range | 20–200 ml/min | |

| Furnace Dimensions (L×H×D) | 760×900×610 mm | |

| Weight | Approx. 90 kg | |

| Temperature Control System |  |

Programmable sintering curves with dynamic curve display Multi-segment scheduling and unattended operation capability Real-time display and recording of power, voltage, and temperature data Data export function for paperless documentation Remote monitoring and control of furnace status Temperature calibration with non-linear correction between control and sample temperature throughout the sintering process |

| Heating Elements |  |

Mo-doped Fe-Cr-Al alloy heating wires |

| Vacuum Reaction Vessel |  |

Austenitic stainless steel reaction tank (310S material), corrosion and oxidation resistant |

| Weakly Corrosive Gas Preheater(Optional) |  |

Made of 316L stainless steel, suitable for preheating various gases including corrosive gases, max temp. up to 600°C |

| Service Support | One-year warranty with lifetime support (warranty excludes consumable parts such as heating elements and thermocouple). | |

Applications

-

Molten Salt Electroplating

- Deposition of metals such as aluminum, magnesium, titanium, and rare earth metals in molten salt electrolytes.

- Production of dense, uniform, and strongly bonded metallic coatings on complex-shaped components.

- Ideal for coating refractory metals or substrates that require high-temperature electrochemical processing.

-

Electrochemical Metallurgy

- High-temperature molten salt electrolysis for extracting and refining reactive metals.

- Laboratory-scale simulation of industrial processes like aluminum and magnesium smelting.

- Synthesis of advanced alloys through electrodeposition techniques.

-

Surface Modification and Diffusion Coating

- Creating diffusion layers through solid-state diffusion between the deposited layer and the substrate, enhancing surface hardness, wear resistance, and corrosion resistance.

- Production of protective coatings for aerospace, automotive, and energy applications.

-

High-Temperature Electrolysis Research

- Investigation of electrochemical processes in molten salts for materials discovery and energy storage applications.

- Development of novel electrode materials and electrolytes for molten salt systems.

-

Advanced Materials Processing

- Fabrication of functional coatings, including thermal barrier coatings (TBCs) and corrosion-resistant layers.

- Research on high-temperature ionic conductors and molten salt chemistry.

|

|

Why Choose ZYLAB Vacuum Molten Salt Electroplating Furnace?

-

Advanced Temperature Control: Guarantees consistent and reliable results in high-temperature electrochemical processes.

-

Safe Operation: Integrated real-time monitoring ensures a safe working environment.

-

Customizable Options: Tailored designs available to meet specific research or production requirements.

-

Global Service & Support: ZYLAB provides professional technical support and lifetime service.

|

|

Click Here to View:How Laboratory Molten Salt Electric Heating Furnaces Are Transforming the Aluminum Electrolysis Industry

Additionally, we provide molten salt electrolysis furnace designed for metal refining and smelting applications. For more tube furnaces, box furnaces, vacuum furnaces, and other high-temperature furnaces, click here to view!