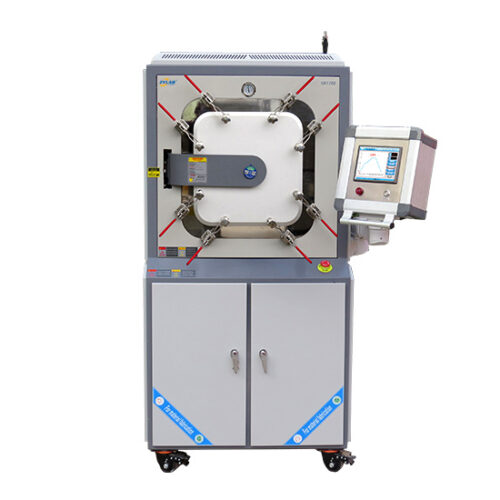

ZYLAB 64L Vacuum Atmosphere Muffle Furnace

Introduction

The ZYLAB 64L 5-Side Heating Vacuum Atmosphere Muffle Furnace is a high-performance laboratory furnace designed for high-temperature heat treatment under vacuum or controlled atmosphere conditions. Featuring a five-sided heating structure (front, rear, left, right, and bottom), this furnace delivers exceptional temperature uniformity and precise thermal control throughout the entire chamber.

With a 400 × 400 × 400 mm heating chamber (64 liters), advanced PID temperature control, and integrated vacuum & gas atmosphere system, this furnace is ideal for applications requiring a clean, oxygen-free, and highly stable thermal environment.

It is widely used in materials science, metallurgy, semiconductor processing, powder sintering, advanced ceramics, and R&D laboratories.

Key Features

1. Five-Sided Heating Design for Superior Uniformity

-

5-side heating configuration ensures even heat distribution from all directions

-

Multi-zone heating control, each zone independently regulated

-

Significantly improved temperature uniformity, minimizing thermal gradients

2. Vacuum & Controlled Atmosphere Processing

-

High-efficiency vacuum pump system enables rapid evacuation to the required vacuum level

-

Supports oxygen-free heat treatment, preventing oxidation and contamination

-

Atmosphere control system allows introduction of inert gases such as:

-

Argon (Ar)

-

Nitrogen (N₂)

-

3. Precise Temperature Control & Stability

-

Advanced PID control algorithm for accurate temperature regulation

-

Control accuracy: ±1°C

-

K-type thermocouple for real-time temperature feedback

-

Five-sided heating structure greatly enhances thermal consistency across the chamber

4. Intelligent & Automated Control System

-

Embedded operating system with bilingual (Chinese / English) graphical interface

-

7-inch true-color touchscreen with intuitive human-machine interaction

-

Non-linear temperature correction for higher process accuracy

5. Data Recording & Remote Monitoring

-

Automatic recording of key process parameters

-

Data supports process analysis and optimization

-

Network-enabled design allows remote monitoring and system status management

Technical Specifications

| Model | VA1200-40 | |

| Heating Chamber Volume | 64 L | |

| Chamber Size (W × H × D) | 400 × 400 × 400 mm | |

| Max Temperature | 1200°C | |

| Temperature Accuracy | ±1°C | |

| Heating Rate | 1°C/h – 20°C/min | |

| Heating Elements | Alloy resistance wire | |

| Power Supply | AC 380V, Three-phase five-wire | |

| Rated Power | 10 kW | |

| Temperature Sensor | K-type thermocouple (φ1 × 350 mm) | |

| Touch Screen | 7-inch | |

| Gas Flow Control | Float flowmeter 0.3–3 L/min | |

| Furnace Dimensions | 980 × 1790 × 910 mm (L × H × D) | |

| Net Weight | Approx. 400 kg | |

| Control System |  |

|

| Water Storage Tank (Cooling System) |  |

|

| Atmosphere Protection Box (Optional) |  |

|

| Warranty & Support | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. | |

Typical Applications

-

Advanced ceramics sintering

-

Powder metallurgy heat treatment

-

Semiconductor material annealing

-

Battery material research

-

Metal and alloy oxidation prevention

-

Materials science and university research laboratories

For More Content

Please read our blog: Applications of Vacuum Furnaces in Materials Preparation: An In-Depth Guide

For More Options on Vacuum Furnace

Please visit our website [Vacuum Furnace Collection]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]