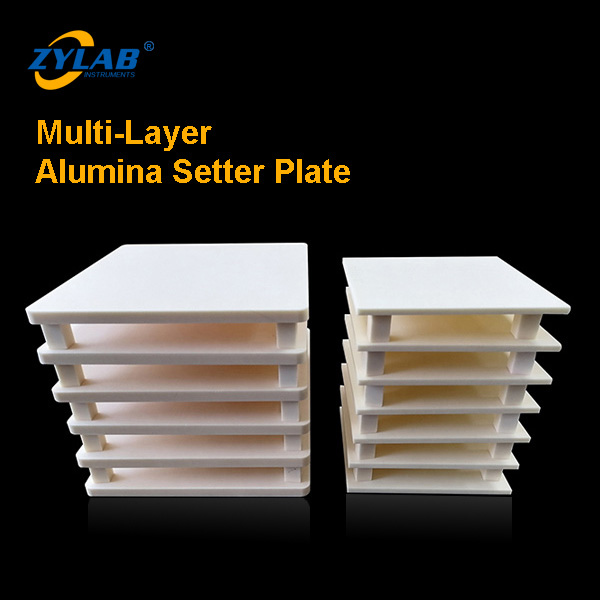

Stackable Setter Plate with Spacers – High-Temp Alumina Supports for Sintering

Introduction:

Stackable Setter Plate with Spacers refers to the accessories used inside a furnace to support the materials being processed or treated. They are made of high purity alumina materials to withstand high temperatures and chemical reactions.

They play a crucial role in various high-temperature processes such as firing, sintering, annealing, and heat treatment in industries like ceramics, metallurgy, glass manufacturing, and semiconductor fabrication.

Advantages of Stackable Setter Plate with Spacers:

1. The material of the product is 99% alumina (Al2O3 > 99%).

2. Adopting slip casting/pressure molding technology.

3. Firing temperature is 1800°C, long-term use temperature ≤1600°C.

4. High temperature resistance and chemical corrosion resistance.

Applications:

- Supporting and positioning materials: Provides a platform for supporting and positioning the materials or samples to be processed.

- Conducting heat: Acts as a medium for heat conduction, helping to transfer heat from the heat source to the materials being processed.

- Preventing contamination: Made of high-purity materials, it does not contaminate the materials being processed.

- Preventing adhesion and deformation: To prevent adhesion or deformation of the materials being processed at high temperatures, thus protecting the surface quality and shape of the materials.

- Improving processing efficiency: Through rational layout and design, can process multiple samples simultaneously or increase processing speed.

Specifications:

99 Alumina Stackable Setter Plate Specification Table (UoM:mm)

| 20×20×1.5 | 20×20×3 | 30×30×2 | 40×30×3 |

| 40×40×3 | 45×23×3 | 50×25×3 | 50×30×3 |

| 50×40×3 | 50×50×3 | 50.8×50.8×0.5 | 50.8×50.8×1 |

| 60×30×3 | 60×40×3 | 60×50×3 | 60×60×3 |

| 60×60×10 | 65×65×3 | 70×70×3 | 75×75×4 |

| 80×40×3 | 80×40×4 | 80×80×4 | 84×75×8 |

| 85×85×4 | 90×60×3 | 90×90×4 | 100×30×3 |

| 100×40×3 | 100×40×6 | 100×40×9 | 100×50×3 |

| 100×50×9 | 100×60×3 | 100×65×3 | 100×84×1.5 |

| 100×84×3 | 100×84×4 | 100×84×6 | 100×100×3.5 |

| 100×100×5 | 100×100×7 | 100×100×8 | 101.6×101.6×0.5 |

| 101.6×101.6×1 | 105×105×4 | 110×110×4 | 115×55×3 |

| 115×65×4 | 115×115×4 | 120×60×5 | 120×80×5 |

| 120×120×4 | 120×120×6 | 120×120×10 | 130×130×6 |

| 135×120×7 | 140×140×6 | 150×130×7 | 150×150×6 |

| 150×150×7 | 155×40×4 | 160×120×5 | 160×140×5 |

| 160×160×6 | 180×180×6 | 190×190×4 | 200×100×6 |

| 200×150×5 | 200×200×8 | 220×220×8 | 230×115×30 |

| 230×230×8 | 250×155×9 | 250×250×8 | 300×150×8 |

| 300×200×8 | 300×300×6 | 310×185×8 | 320×90×10 |

| 320×100×10 | 160×140×9 | 320×320×6 | 330×330×15 |

95 Alumina Stackable Setter Plate Specification Table (UoM:mm)

| 10×10×1 | 100×100×4 | 100×100×10 | 115×70×10 |

| 130×32×10 | 133×133×6 | 135×30×10 | 135×30×10 |

| 135×135×5 | 140×85×10 | 150×100×10 | 150×140×8 |

| 150×150×6 | 150×150×8 | 150×150×10 | 160×160×8 |

| 250×250×10 | φ20×2 | φ40×3 | φ45×4 |

| φ70×5 | φ100×5 | φ105×7 |

99 Alumina Spacers Specification Table (UoM:mm)

| Square Type | |||

| 4×4×4 | 4×4×6 | 4×4×7 | 5×5×3 |

| 5×5×4 | 5×5×5 | 5×5×7.5 | 15×10×8 |

| 15×10×10 | 19×9×6 | 20×15×12 | 20×20×20 |

| Cylinder Type | |||

| Ф8×6 | Ф18×15 | Ф30×20 | Ф35×13 |

| Ф35×20 | |||

Why Choose ZYLAB ?

-

Precision-made furnace furniture for laboratory furnaces.

-

Proven performance in high-purity and high-temperature applications.

-

Fast delivery and global shipping.

-

Customization support from design to final shipment.

Click to See More Content:

A Furnace Furniture Solution Composed of Alumina Plates and Stands

Custom Alumina Furnace Furniture | Drilling, Engraving and Grooving

For More Options on Alumina(Al2O3) Ceramic Products

Please visit our website [Alumina(Al2O3) Ceramic Products]

For More Options on Furnace Furniture

Please visit our website [Furnace Furniture Collection]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection ]