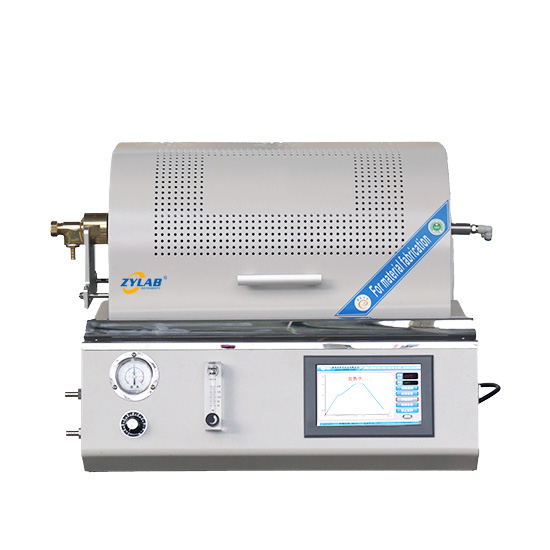

ZYLAB 1200°C Rocking Tube Furnace

Product Description:

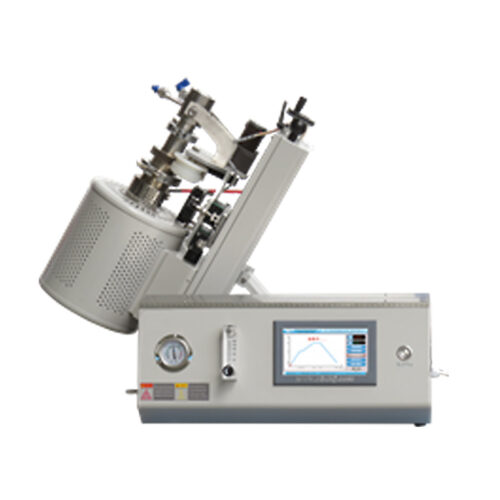

The ZYLAB laboratory 1200°C rocking tube furnace is a high-performance laboratory sintering and heat treatment system designed for advanced material research and industrial R&D. Featuring a rocking (oscillating) tube design, the furnace enables continuous mixing and uniform heating of powders and granular samples, ensuring optimal reaction kinetics and material properties.

It is widely used for the processing of:

-

Lithium-ion battery cathode and anode materials (LiFeAlPO₄, LiMn₂O₄, LiCoO₂, NCM ternary, graphite anode, etc.)

-

Rare earth materials

-

Chemical catalyst materials

-

Magnetic materials

-

Powder metallurgy materials

-

Non-ferrous metal materials

-

Kaolin and other non-metallic minerals

Typical applications include laboratory-scale calcination, drying, high-temperature reactions, thermal treatment, and carbonization under controlled atmosphere or vacuum conditions.

Key Features:

-

Rocking Tube Design – Continuous material movement for uniform heating and complete reaction.

-

Vacuum & Atmosphere Control – Compatible with inert, reducing, and mixed gases for versatile applications.

-

High-Purity Al₂O₃ Fiber Insulation – Superior thermal efficiency and significant energy savings.

-

Protective Alumina Coating – Extends furnace lifespan and resists chemical corrosion.

-

Double-Shell Steel Construction – Durable and safe design with efficient heat dissipation.

-

Dynamic Sealing System – Maintains stable atmosphere or vacuum conditions during rocking operation.

-

Intelligent PID Control – Programmable temperature curves with excellent accuracy and repeatability.

-

Integrated Systems – Includes heating, vacuum, gas flow, motion, process monitoring, and data acquisition.

Applications of Rocking Tube Furnace:

-

Battery Materials

-

Sintering and calcination of lithium-ion cathode and anode powders (LiFeAlPO₄, LiMn₂O₄, LiCoO₂, NCM ternary, graphite, etc.)

-

-

Catalyst Preparation

-

Heat treatment of chemical and petrochemical catalysts for improved activity and stability

-

-

Advanced Ceramics & Non-Metallic Minerals

-

Processing kaolin, ceramic powders, and other functional non-metallic materials

-

-

Powder Metallurgy & Non-Ferrous Metals

-

Sintering and thermal processing of metallic powders and alloy materials

-

-

Magnetic & Rare Earth Materials

-

High-temperature reactions for ferrites, magnetic compounds, and rare earth-based functional materials

-

-

Research & Development

-

Laboratory-scale calcination, drying, high-temperature reactions, carbonization, and thermal treatments under vacuum or controlled atmospheres

-

Technical Parameters:

| Model | RT1200-50TIF | |||||

| Power supply | AC220V 1.5KW | |||||

| Max. temperature | 1200 ℃(<1 hour) | |||||

| Working temperature | 1150 ℃ (continuing) | |||||

| Heating rate | ≤ 20 ℃/min | |||||

| Length of heating zone | 200mm | |||||

| Effective Volume | 55ml | |||||

| Intelligent Touch Screen

Temperature controller |

• Centralized control 7” color LCD touch screen man-machine English graphics interface, clear heating process, more intuitive and convenient operation.

•30 programmable segments for precise control. •Can store sintering programs to avoid the trouble caused by repeated settings of different processes. •Built in protection for over-heated and broken thermal couple, and leakage. |

|||||

| Temperature accuracy | +/- 1 ℃ | |||||

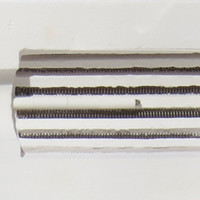

| Heating element |

Molybdenum-Doped Fe-Cr-Al Alloy High-Temperature Heating Wire |

|||||

| Sealing System |

|

|

||||

| Vacuum level:≤10Pa(Mechanical Pump) | ||||||

| Pressure Measurement and Monitoring |

Utilizing a mechanical pressure gauge with shock-absorbing oil to introduce damping effects during pressure fluctuations, reducing the back-and-forth oscillation of the pointer. |

|||||

| Dimension | 740(L) * 480(W) * 480(H)mm

|

|||||

| Net weight | 30KG | |||||

| Warranty | One-year warranty, lifetime support (excluding consumable parts such as furnace tubes, O-rings ) | |||||

The furnace can be equipped with a gas pre-heating system specially designed. The entire pre-heater is made of 316L stainless steel, ensuring durability and resistance to corrosion. It allows pre-heating of various gases, including corrosive gases, to meet special process requirements. The maximum pre-heating temperature reaches 600°C.

Safety and Operating Instructions:

-

Do not open the furnace chamber when the temperature is ≥300°C to avoid personal injury.

-

The pressure inside the furnace tube must not exceed 0.125 MPa (absolute pressure) during operation, in order to prevent equipment damage.

-

When operating under vacuum conditions, the maximum allowable temperature is 800°C.

-

Since gas cylinders are supplied at high pressure, a pressure-reducing valve must be installed before introducing gas into the furnace tube. It is recommended to use a low-pressure regulator with a range of 0.01 MPa – 0.15 MPa for higher precision and safety.

-

When the furnace temperature is above 1000°C, the tube must not remain under vacuum. The internal pressure should be maintained close to atmospheric pressure (ambient pressure).

-

For high-purity quartz tubes, the maximum recommended continuous operating temperature is ≤1100°C.

-

During heating experiments, it is not recommended to completely close both the inlet and outlet valves on the tube flange. If closed-valve heating is required, the pressure gauge must be closely monitored. If the absolute pressure exceeds 0.15 MPa, the exhaust valve must be opened immediately to prevent accidents (e.g., tube rupture or flange ejection).

-

This equipment is recommended for micron-sized powders or granular samples. The use of nano-powders is not advised with this model.

Advantages of ZYLAB Furnaces:

-

Flexible Customization – Designed to meet diverse laboratory demands

-

Widely Used in Research and Industry – Reliable performance in materials labs, universities, and production environments

-

Professional Support – Dedicated technical service and documentation

-

Efficient Logistics – Timely delivery and global shipment options

Click to See More Content

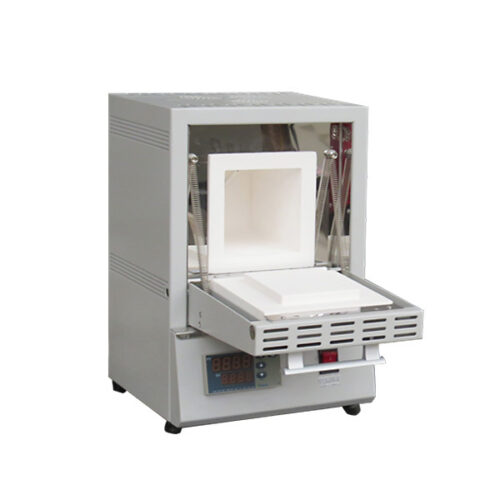

For More Options on Tube Furnaces

Click here [Tube Furnaces Collection]

For More Options on High Temperature Furnaces

Click here [High Temperature Furnaces Collection]