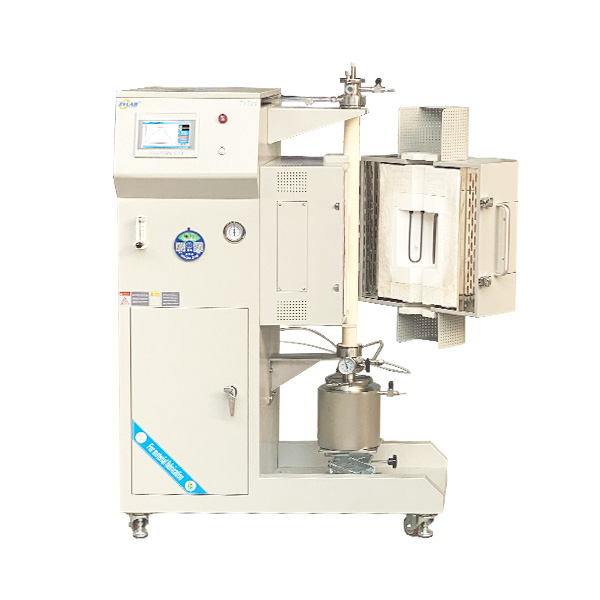

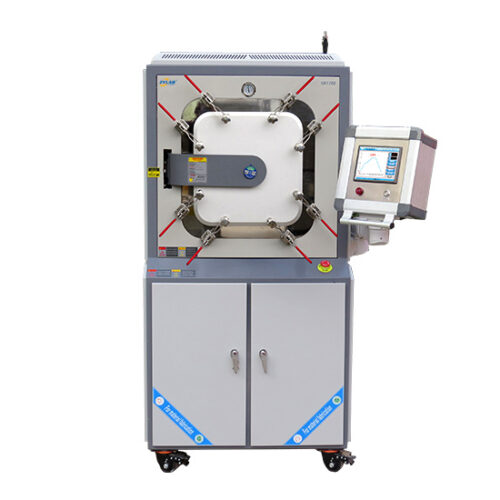

ZYLAB 1700°C Vertical Atmosphere Controlled Quenching Furnace

Introduction

The ZYLAB 1700°C High Temperature Atmosphere Controlled Quenching Furnace for Vertical Tube is a specialized vertical furnace designed for high-performance quenching processes. It is widely used in aerospace, automotive, mechanical engineering, and materials science fields where precision heat treatment is essential.

With advanced temperature and atmosphere control capabilities, this furnace ensures uniform heating and rapid quenching, enabling parts to achieve enhanced hardness, strength, and wear resistance. It is ideal for processing tool steel, high-speed steel, mold steel, and other components requiring strict metallurgical performance.

Key Features

1. High-Efficiency Heating

-

Premium Heating Elements

Equipped with high-quality MoSi₂ (silicon molybdenum) heating rods that deliver fast heating rates and long service life, even under extreme high-temperature conditions. -

Precise Temperature Control

Uses an advanced PID temperature controller with multi-stage programmable settings. It ensures high temperature accuracy, excellent repeatability, and real-time thermal feedback. -

Uniform Temperature Distribution

Optimized furnace chamber design and strategic heating element layout ensure consistent temperature across the entire heating zone, preventing hot spots and cold zones. This guarantees uniform quenching results for all workpieces.

2. Accurate Atmosphere Control

-

Atmosphere Flexibility

The furnace is compatible with various process atmospheres including vacuum, inert gases (argon, nitrogen), and reducing gases (hydrogen). It supports customized atmosphere conditions based on different heat treatment requirements. -

Atmosphere Switching Function

Allows dynamic switching between different gas environments during the heating or cooling cycle to meet complex experimental or production needs.

3. Vertical Design Advantages

-

Space-Saving Configuration

The vertical design provides a compact footprint, making it ideal for laboratories and manufacturing environments with limited space. -

Convenient Loading & Unloading

Features a top or bottom loading port for easy and safe handling of components. Especially suitable for long or slender parts that are sensitive to distortion. -

Minimized Deformation Risk

Vertical orientation supports the weight of the sample along its axis, reducing the likelihood of deformation during high-temperature treatment—ideal for shafts, rods, and bar-shaped materials.

4. User-Friendly Operation

-

Touchscreen Control Panel

Integrated with an intuitive touchscreen interface that enables easy parameter setup, real-time data logging, and optional remote monitoring capabilities. -

Pre-Programmed Quenching Cycles

Comes with a library of customizable and pre-installed quenching programs, allowing users to quickly select or modify process recipes to match specific treatment goals. -

Low Maintenance Design

Durable construction, easy access to internal components, and self-diagnosis features simplify daily operation and reduce downtime.

Applications of Atmosphere Controlled Quenching Furnace

-

Heat treatment and quenching of high-performance metals

Suitable for tool steels, high-speed steels (HSS), die steels, and other alloy materials requiring high hardness, strength, and wear resistance. -

Vacuum and atmosphere-controlled quenching experiments

Ideal for laboratory research involving precise control of inert or reducing gas environments, such as argon, nitrogen, or hydrogen atmospheres. -

Aerospace and automotive component processing

Applied in the thermal treatment of structural and functional parts used in aerospace engines, turbines, transmission systems, and other high-demand applications. -

Long or vertically oriented sample processing

The vertical design makes it particularly suitable for heat treating elongated components, such as rods, shafts, and bar-shaped samples, while minimizing thermal deformation. -

R&D in material science and metallurgy

Frequently used in research institutes and university laboratories for the development and optimization of heat treatment processes and metallurgical properties.

Technical Specifications of Atmosphere Controlled Quenching Furnace

| Model | LT1700-60-200 | |

| Power Supply | Single phase 220V, 50Hz | |

| Rated Power | 4.5 kW | |

| Sensor Type | Type B thermocouple, Φ8 × 150 mm | |

| Maximum Temperature (Tmax) | 1650°C | |

| Heating Rate | 1°C/hour – 20°C/minute (adjustable) | |

| Temperature Accuracy | ±1°C | |

| Heating Zone Length | 200 mm | |

| Furnace Chamber Size (W×H×D) | 140 × 200 × 140 mm | |

| Overall Dimensions (W×H×D) | 1075 × 1500 × 610 mm | |

| Net Weight | 260 kg | |

| Heating Element |  |

High-purity MoSi₂ (silicon molybdenum) rods |

| Control System |  |

|

| Quenching System |  |

Equipped with an automatic lifting mechanism that rapidly transfers the workpiece into the quenching tank upon completion of the holding stage, ensuring full immersion in the quenching medium |

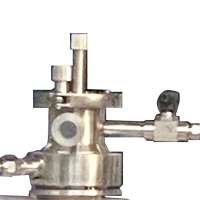

| Sealing System |  |

|

| Vacuum level: 10 Pa (with mechanical pump) | ||

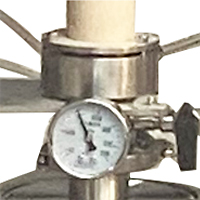

| Pressure Monitoring |  |

Mechanical pressure gauge with airtight casing for corrosion and high-temperature resistance |

| Gas Supply System |  |

Integrated with float flow meter for precise gas flow control; leak-tested before delivery |

| Preheater for Mildly Corrosive Gases (Optional) |  |

Made of 316L stainless steel; preheats various process and corrosive gases up to 600°C to meet special treatment needs |

| Warranty & Support | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. | |

For More Content

Please read our blog: Tube Furnace Guide: Models, Applications & Custom Options

For More Options on Tube Furnaces

Please visit our website [Tube Furnaces]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]