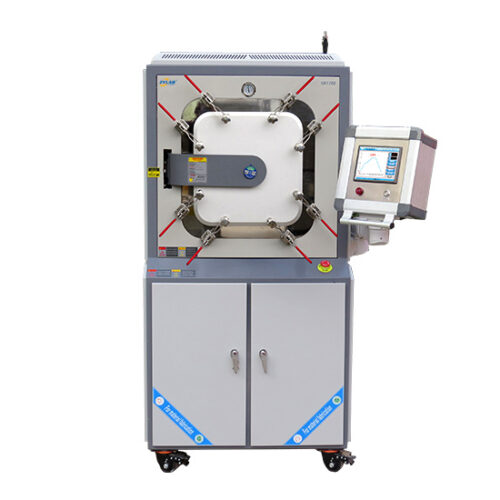

ZYLAB Vacuum Brazing Furnace

Introduction

The ZYLAB Vacuum Brazing Furnace is an advanced high-temperature system designed for precision brazing under a high-vacuum environment. It ensures clean, strong, and oxidation-free joints, making it ideal for industries that demand high-quality metal bonding.

With precise atmosphere control, uniform heating, and a user-friendly interface, this furnace enhances brazing efficiency while minimizing defects such as voids and impurities.

Key Features

1. High-Vacuum Environment for Clean Brazing

-

Efficient Vacuum System: Equipped with a high-performance vacuum pump, capable of rapidly achieving a high-vacuum state. This prevents oxidation and contamination during the brazing process.

-

Stable Vacuum Conditions: Maintains a consistent vacuum level, ensuring optimal brazing results.

2. Uniform & Precise Heating

-

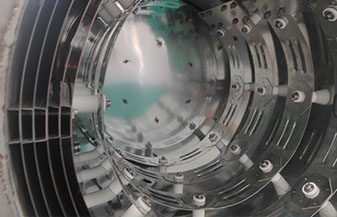

High-Quality Heating Elements: Uses molybdenum belt heating elements for rapid heating and even temperature distribution.

-

Advanced PID Temperature Control: Multi-segment programmable temperature control with high precision and repeatability.

-

Optimized Temperature Uniformity: Engineered heating element layout prevents localized overheating or cold spots, ensuring consistent results.

3. User-Friendly Operation & Automation

-

Intuitive Touchscreen Interface: Simplifies operation with real-time data recording and remote monitoring.

-

Pre-Set Heating Programs: Offers multiple pre-configured programs for different brazing applications, reducing setup time.

-

Easy Maintenance: Designed for convenient cleaning, calibration, and long-term reliability.

Applications

1. Aerospace Industry

-

Brazing of aircraft engine components and structural parts.

-

Ensures high-strength, oxidation-free joints for mission-critical aerospace applications.

2. Automotive Manufacturing

-

Used for brazing high-performance engine components, heat exchangers, and transmission parts.

-

Enhances the durability and performance of welded assemblies.

3. Electronics & Semiconductor Industry

-

Ideal for precision assembly of semiconductor chips, heat sinks, and electronic packaging.

-

Ensures reliable micro-joining with minimal thermal stress.

4. Precision Machinery & Medical Devices

-

Used for manufacturing medical instruments, watches, and high-precision mechanical components.

-

Delivers high-strength, defect-free bonds for intricate designs.

5. Research & Development

-

Suitable for universities, R&D institutes, and material science laboratories studying brazing and material bonding technologies.

Technical Specifications of Vacuum Brazing Furnace

| Model | VAH1600 | |

| Power Supply | Three-phase 380V, 50Hz | |

| Rated Power | 45KW | |

| Temperature Zones | Single zone, single control | |

| Sensor Type | S-type thermocouple, Φ8×300mm | |

| Flow Meter | 20-200L/min | |

| Maximum Temperature (Tmax) | 1300°C (Recommended operating temperature: ≤1200°C) | |

| Chamber Material | 304 Stainless Steel + Molybdenum Plate | |

| Chamber Dimensions | Φ392×410mm | |

| Effective Working Area | 200mm (L) × 200mm (H) × 300mm (D) | |

| Recommended Heating Rate | ≤10°C/min | |

| Vacuum Pump | BSV90 KF40 interface (Ultimate vacuum: 4Pa) | |

| Molecular Pump | Inlet CF200, Outlet KF40 (Ultimate vacuum: 5×10⁻⁶Pa) | |

| Ultimate Vacuum | 6.7×10⁻³Pa (Empty furnace, cold state) | |

| Furnace Dimensions | 1835mm (L) × 2040mm (H) × 1625mm (D) | |

| Water Chiller Dimensions | 706mm (L) × 1235mm (H) × 1035mm (D) | |

| Control System |  |

|

| Temperature Accuracy | ±1°C | |

| Heating Elements |  |

Molybdenum Belt Heating Chamber |

| Pressure Measurement & Monitoring |  |

Integrated float flow meter for gas flow control, pre-tested for leakage before delivery |

| Gas Supply System |  |

Equipped with a mechanical pressure gauge in a sealed housing for corrosion and high-temperature resistance |

| Net Weight | Approx. 1215KG | |

| Usage Precautions |

|

|

| Service & Support |

|

|

For More Options on Vacuum Furnaces

Please visit our website [Vacuum Furnaces Collection]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]