Split Type 100-Ton Hydraulic Electric Powder Pellet Press with Safety Shield

Applications:

This electric powder pellet press is mainly used for samples that require high pressure for shaping, such as ceramics, metal powders, and various large-sized molds.

Introduction:

The hydraulic press adopts a split-type structure and operates fully automatically through programmed procedures: programmed pressurization/gradual pressurization, pressure holding, pressure supplementation, timed pressure release, etc. It features a liquid crystal display screen for intuitive and simple operation. Equipped with plexiglass protective cover as standard, ensuring safe and reliable operation. It offers stable pressure and convenient operation.

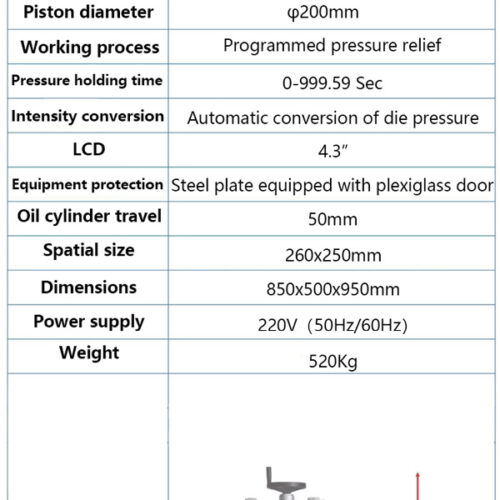

Technical specifications:

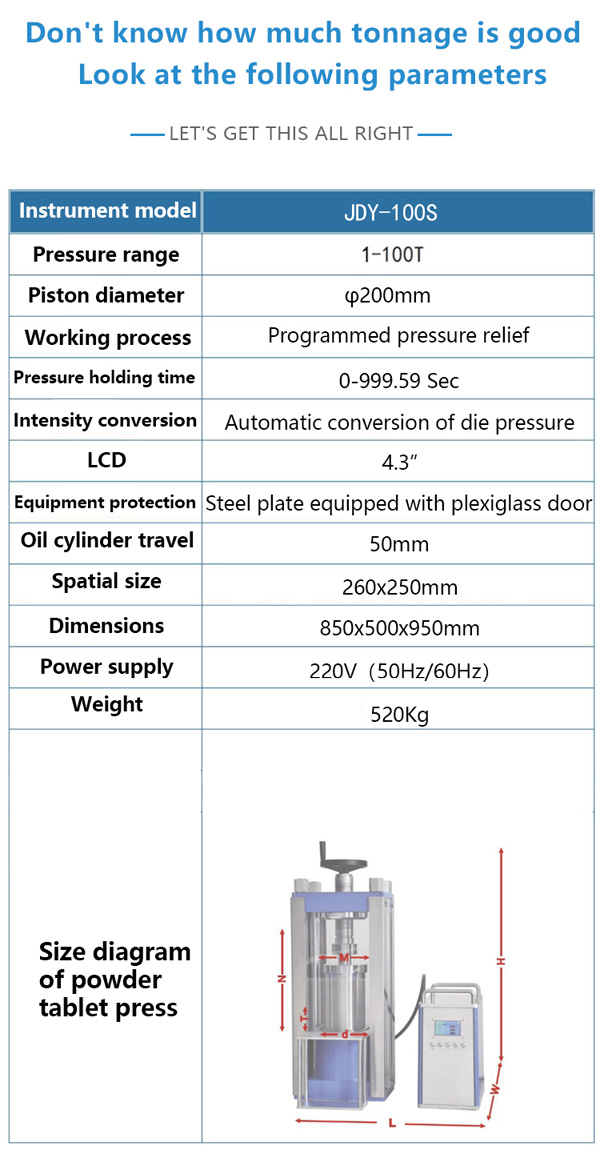

| Pressure range | 1-100T |

| Piston diameter | Chrome-plated oil cylinder Φ200mm(d) |

| Pressurization process | Programmed pressurization – Programmed pressure holding – Timed pressure release |

| Pressure holding time | 0-999 seconds/minute |

| Pressure conversion | Automatically converts the pressure borne by the sample |

| LCD display | 4.3-inch LCD screen |

| Equipment protection | Steel plate protection with plexiglass door |

| Oil cylinder stroke | 50mm(T) |

| Space dimension | 260×250mm (M×N) with optional higher pillars |

| Overall dimension | 850×500×950mm (L×W×H) |

| Power supply | 220V(50Hz/60Hz) |

| Weight | 520kg |

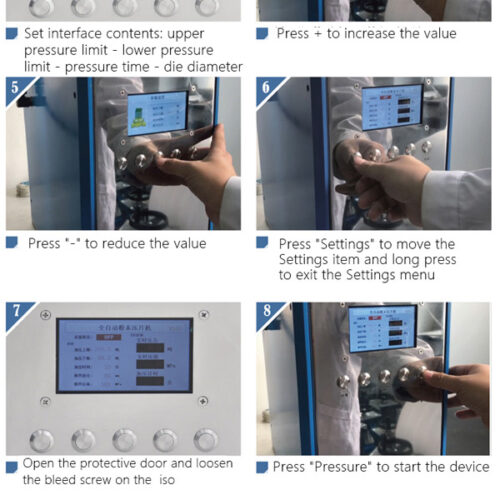

Operating steps:

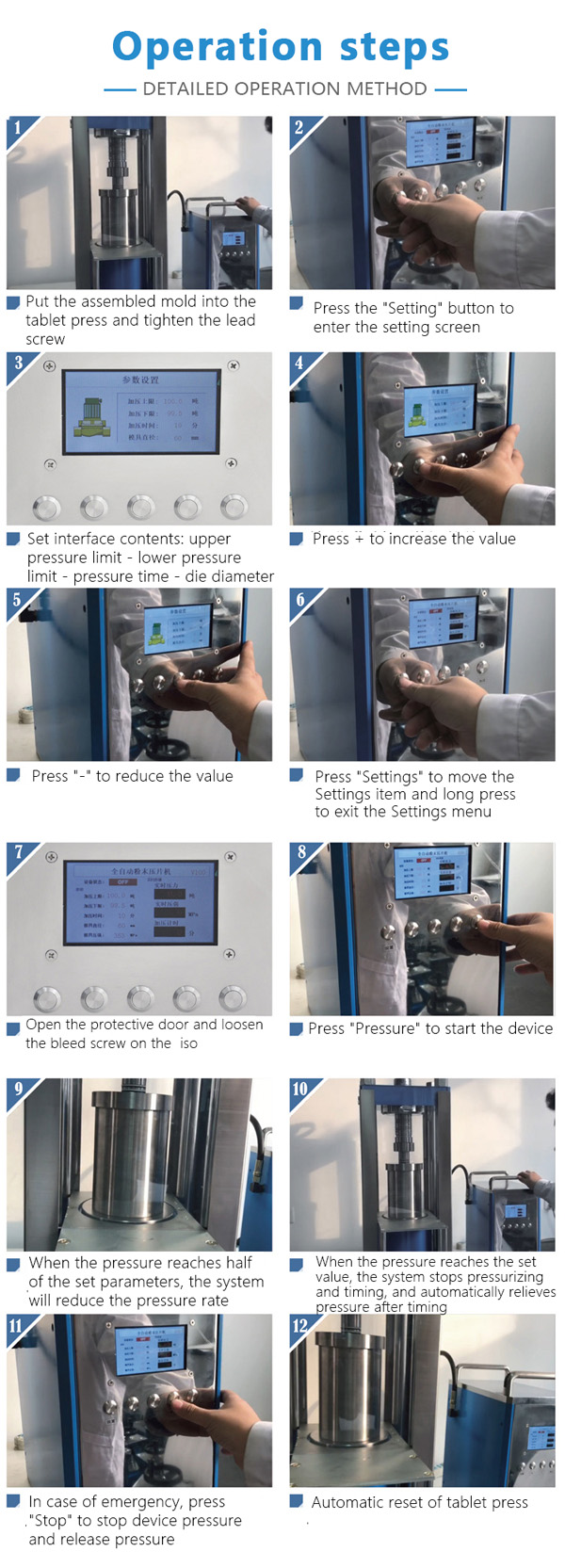

- Place the assembled mold into the press and tighten the screw;

- Press the “Settings” button to enter the settings interface;

- Settings interface content: upper limit pressure – lower limit pressure – pressurization time – mold diameter;

- Press the “+” key to increase the value;

- Press the “-” key to decrease the value;

- Press the “Settings” key to move the setting item, long press to exit the setting menu;

- Return to the operating menu;

- Press the “Pressurize” button to start the equipment;

- When the pressure reaches half of the set parameter, the system will reduce the pressurization speed;

- When the pressure reaches the set value, the system stops pressurizing and starts timing, followed by automatic pressure release;

- In case of emergency, press the “Stop” button to stop the equipment from pressurizing and release the pressure;

- The press resets automatically.

Others:

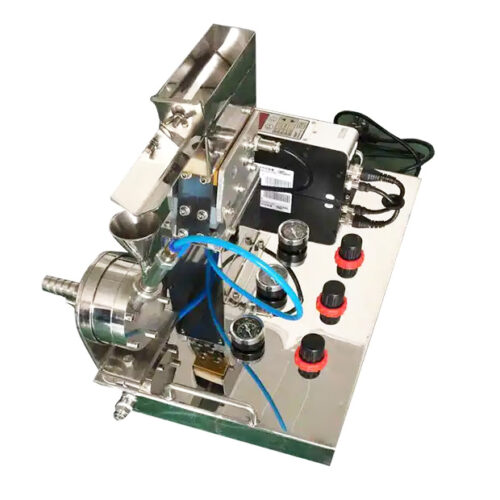

Optional- Matching Dry Pellet Pressing Die Set