ZYLAB High Purity Zirconia Planetary Mill Jars

Introduction:

The ZYLAB Zirconia Planetary Mill Jar is designed for high-efficiency grinding, mixing, and homogenization in laboratory planetary ball mills. Made from high-purity zirconia (ZrO₂), this jar offers exceptional hardness, superior wear resistance, and outstanding chemical stability. It ensures minimal contamination during milling, making it ideal for precise material processing in research and industrial applications.

Pure zirconia is a white solid with a theoretical density of 5.89 g/cm³ and a melting point of 2715°C. Depending on impurities or dopants, it may appear gray, light yellow, or other colors. Compared with alumina jars, the zirconia jar provides even higher mechanical strength and lower abrasion loss, ensuring longer service life and cleaner results.

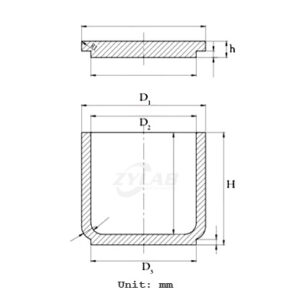

The ZYLAB Zirconia Planetary Milling Jar adopts a large-radius R-corner design at the bottom and a flat sealing gasket structure at the jar mouth, providing smooth rotation, excellent sealing, and stable performance during high-speed operation.

In addition to zirconia, ZYLAB also offers planetary milling jars made from a variety of other materials, including stainless steel, alumina, agate, cemented carbide, and silicon nitride. Each type is carefully designed to meet different research and material processing requirements.

Contact us today to discuss your specific application needs.

Key Features:

-

High Wear Resistance: Outstanding durability and long service life under frequent, high-speed milling conditions.

-

Low Contamination: Zirconia material ensures minimal impurity introduction into the sample.

-

High Hardness & Strength: Resistant to cracking and impact during extended milling cycles.

-

Chemical Inertness: Excellent resistance to most solvents such as acetone, ethanol, and acids.

-

Smooth Surface Finish: High polish minimizes material adhesion and facilitates easy cleaning.

-

High Milling Efficiency: Enhances grinding performance and maintains sample purity.

-

Excellent Sealing Design: Flat sealing gasket and precision joint prevent material leakage.

Specifications of Zirconia Planetary Mill Jar:

| Capacity | Outer Diameter (D) | Inner Diameter (D2) | Bottom Diameter (D3) | Height (H) | Lid Thickness (h) |

|---|---|---|---|---|---|

| 50 mL | 64 | 50 | 64 | 56 | 12 |

| 100 mL | 74 | 60 | 64 | 68 | 12 |

| 250 mL | 94 | 80 | 89.5 | 88 | 13 |

| 500 mL | 103 | 89 | 89.5 | 100 | 13 |

| 1 L | 130 | 114 | 119.5 | 118 | 13 |

Note: Dimensions are standard. Custom sizes can be provided upon request.

Applications:

-

Rare earth material grinding

-

Advanced ceramics and powder metallurgy

-

Pharmaceutical and biomedical research

-

Chemical and materials engineering

-

Geological and metallurgical analysis

-

Nanomaterial synthesis and sample preparation

Matched Planetary Ball Mill:

| Model | Spec | With ball mill jar | Remarks | |

| Spec(ml) | Quantities | |||

| M-0.4L | 0.4L | 50-100ml | 2 or 4 | With 50ml vacuum ball mill jar |

| M-1L | 1L | 50-250ml | 2 or 4 | With 50-100ml vacuum ball mill jar |

| M-2L | 2L | 50-500ml | 2 or 4 | With 50-250ml vacuum ball mill jar |

| M-4L | 4L | 50-1000ml | 2 or 4 | With100-500ml vacuum ball mill jar |

| M-8L | 8L | 500-2000ml | 2 or 4 | With250-1000ml vacuum ball mill jar |

| M-10L | 10L | 500ml-2.5L | 2 or 4 | With 250-2.5L vacuum ball mill jar |

| M-12L | 12L | 1L-3L | 2 or 4 | With 500-3L vacuum ball mill jar |

| M-16 | 16L | 1L-4L | 2 or 4 | With 500-4L vacuum ball mill jar |

| M-20L | 20L | 1L-5L | 2 or 4 | With 1000-5L vacuum ball mill jar |

| M-40L | 40L | 4L-10L | 2 or 4 | With 3L-10L vacuum ball mill jar |

| M-60L | 60L | 6L-15L | 2 or 4 | With 5L-15L vacuum ball mill jar |

| M-80L | 80L | 6L-20L | 2 or 4 | With 5L-20L vacuum ball mill jar |

| M-100L | 100L | 10L-25L | 2 or 4 | With 9L-25L vacuum ball mill jar |