ZYLAB Clean-Type Vacuum Box Furnace

Introduction

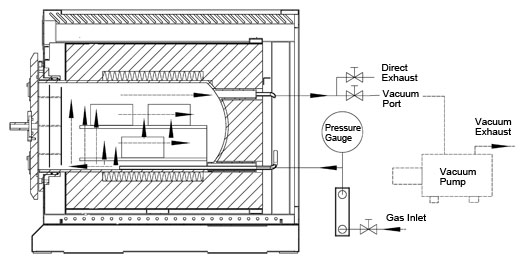

The ZYLAB Clean-Type Vacuum Box Furnace is designed for high-precision heat treatment processes requiring clean environments and uniform temperature control. The system uses ring-shaped heating elements to heat the high-purity quartz vacuum chamber evenly from the outside, ensuring high thermal efficiency, rapid heating, and excellent temperature uniformity.

The furnace provides a clean and stable working atmosphere through a forward–rear circulating gas flow design. All sealing parts are made of high-temperature-resistant O-rings, supported by a water-cooled stainless steel sealing system for enhanced safety and reliability.

With a fully automated touchscreen control system, the furnace offers easy operation and includes comprehensive safety functions, such as over-temperature protection, thermocouple break detection, and low water-pressure alarms.

Key Features

-

Dual-layer insulation structure with air-cooled interlayer – minimizes external temperature rise and improves operational safety.

-

High-purity Al₂O₃ fiber insulation – provides excellent thermal stability and maximum energy efficiency.

-

Refractory chamber coated with high-purity alumina – extends service life and maintains a clean internal environment.

-

High-purity quartz chamber plug – enables customized temperature gradients inside the chamber.

-

Comprehensive protection system – includes over-temperature, thermocouple failure, and cooling-water interruption protection for safe operation.

-

Interchangeable thermocouple port and observation window – flexible configuration for experimental needs.

Technical Specifications of Clean-Type Vacuum Box Furnace

| Model | VAH1200-20 | |

| Working Voltage | AC 208-240V 50/60 Hz (as required) | |

| Power | 4KW | |

| Max.temperature | 1200.C | |

| Working Temperature | <1150.C | |

| Heating Rate | ≤20.C/min(advice:10.C/min) | |

| Heating zone size(mm) | Φ190*200mm | |

| Vacuum Degree | ≤10Pa | |

| Operating Interface | English Graphical Interface | |

| Heating Element | Top quality resistance wire | |

| Control System |  |

|

| Gas Supply System |

|

Utilizes a mechanical pressure gauge with a gas-tight enclosure to effectively protect internal components from environmental effects and contamination. The housing offers excellent corrosion and high-temperature resistance for reliable operation. |

| Pressure Measurement and Monitoring |

|

Equipped with an integrated float-type flowmeter to precisely control gas flow rate. Each unit undergoes leak-tightness testing before delivery to ensure stable and safe gas supply performance. |

| Temperature Accuracy | +/- 1.C | |

| Thermocouple | K Type | |

| Certification | ISO | |

| Dimension | 780(W) * 580(H) * 600(D)mm | |

| Weight | 60kgs | |

| Standard Accessories | Quartz Tube, Vacuum Flange, Tube Block, O-ring, Protective Gloves, Crucible Hook, Manual Book | |

| Warranty | 18 months(not including consumable parts, such as quartz tube, heating elements, thermocouple, etc), lifetime support. | |

Schematic Diagram of Gas Flow in the Clean-Type Vacuum Box Furnace

Applications

-

Advanced materials research – thermal treatment of ceramics, composites, and functional materials.

-

Semiconductor and electronics industry – vacuum annealing, degassing, and oxidation-reduction experiments in a clean environment.

-

Metal and alloy heat treatment – vacuum brazing, annealing, and sintering of small precision components.

-

Ceramic and glass processing – high-purity firing and densification in low-contamination conditions.

-

Thin film and coating studies – heat treatment of substrates and coatings for enhanced adhesion and uniformity.

-

Cleanroom laboratories – suitable for cleanroom-compatible operations requiring minimal contamination and stable temperature control.

For More Options on Vacuum Furnaces

Please visit our website [Vacuum Furnaces Collection]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]