ZYLAB 60-ton Automatic Hydraulic Pellet Press

Introduction:

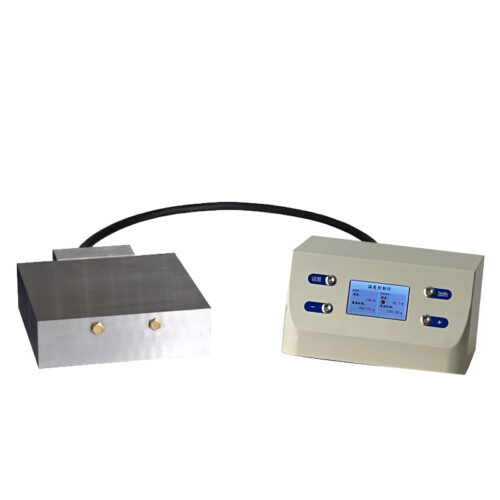

The ZYLAB Laboratory 60-ton Automatic Hydraulic Pellet Press is a high-precision, fully automatic press designed for compacting powder materials in laboratories and R&D facilities. Equipped with a smart programmable control system and a 7-inch touchscreen interface, it enables automatic multi-stage pressure application, real-time monitoring, and precise control over each pressing cycle.

This press is ideal for preparing high-density pellets from materials such as ceramics, metals, catalysts, battery electrodes, and magnetic materials. Its robust frame, advanced safety protection, and intelligent control functions ensure consistent performance and operator safety, making it a reliable choice for laboratory and industrial research applications.

Key Features :

-

Intelligent Automatic Control System

Integrated Savta smart controller supports 5-stage programmable pressure control (upgradeable to 15 stages), enabling complex, multi-step compaction cycles for advanced research needs. -

Fully Automated Pressing Process

Performs automatic pressurization, pressure compensation, timed holding, and automatic pressure release, ensuring stability and repeatability throughout each compaction cycle. -

Automatic Pressure Calculation & Overpressure Alarm

The system automatically converts applied force into actual sample pressure and provides overpressure warnings to protect both the mold and the sample. -

7-inch High-Definition Touch Screen

Features an intuitive 7-inch IPS LCD display with a bilingual (Chinese/English) interface for easy parameter setting and real-time monitoring. -

Reinforced Safety Protection

Built with 10 mm alumina safety shielding and a 6 mm transparent acrylic protective door, providing full protection during high-pressure operation. -

Main Unit & Limit Protection

Includes software and mechanical protection — automatic fault detection, emergency stop, and automatic pressure relief when the system exceeds the rated maximum pressure or cylinder limit. -

Passive Safety Design

Equipped with leakage protection and emergency stop switch, ensuring safe and reliable operation.

Technical Specifications of 60-ton Automatic Hydraulic Pellet Press:

| Model | AP-20 |

| Pressure Range | 1.0 – 60 tons |

| Cylinder Diameter | Φ150 mm |

| Control System | Savta intelligent program control with 5-stage automatic pressure adjustment (optional 15 stages) |

| Pressing Mode | Automatic pressurization → automatic pressure compensation → timed pressure holding → automatic pressure release |

| Holding Time | Unlimited (N seconds) |

| Pressure Conversion | Automatic calculation of actual sample pressure with overpressure alarm |

| Display Screen | 7-inch LCD touch screen, bilingual interface (Chinese/English) |

| Protective Structure | 10 mm high-strength alumina safety plate + 6 mm acrylic protective door |

| Limit Protection | Automatic pressure relief when cylinder exceeds maximum height limit |

| Main Unit Protection | Program and mechanical fault detection with emergency stop; automatic pressure relief when actual pressure exceeds rated maximum |

| Data Management | Stores up to 10,000 operation records; data export via USB |

| Cylinder Stroke | ≤50 mm |

| Demolding Pressure | Adjustable within the rated pressure range |

| Passive Safety Features | Leakage protection and emergency stop switch |

| Smart Operation (Optional) | Computer connection for remote control; customizable software features upon request |

| Power Supply | AC 220V (50/60Hz); optional 110V available |

| Power Consumption | 400 W |

| Effective Space | 190 × 190 × 225 mm |

| Overall Dimensions | 305 × 520 × 585 mm |

| Net Weight | 182 kg |

| Configuration Note | Customizable according to user requirements; compatible with various round, square, irregular, or battery mold types within the rated pressure range |

Applications:

-

Laboratory powder compaction and sample preparation

-

Ceramic, metal, and catalyst material pressing

-

Battery electrode and magnetic material forming

-

Spectroscopy (IR, XRF) pellet preparation

-

High-density compact testing and microstructure analysis

Why Choose ZYLAB Automatic Hydraulic Pellet Press?

-

Precise control, safe design, and reliable automation

-

Trusted by university labs, R&D centers, and material testing facilities

-

Engineered for long-term use with high structural integrity and software flexibility

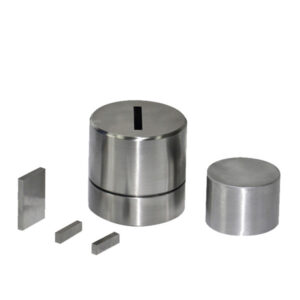

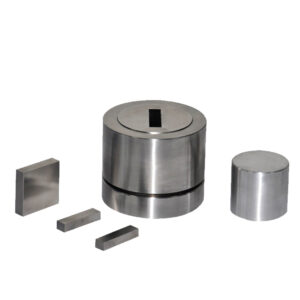

Matching Die Set:

If you require other special-shaped die sets, or specific types such as tungsten carbide dies, XRF-dedicated molds, or electrically heated die sets, please contact our customer service team immediately. Our technical engineers will assist you in evaluating feasibility and providing customized solutions tailored to your application needs.

For More Content

Please read our blog: Laboratory Powder Sample Forming Tools | Pellet Pressing Dies and Press

For More Options on Lab Press

Please visit our website [Lab Press & Rollers]

For More Options on Powder Material Preparation

Please visit our website [Powder Material Preparation Solution]