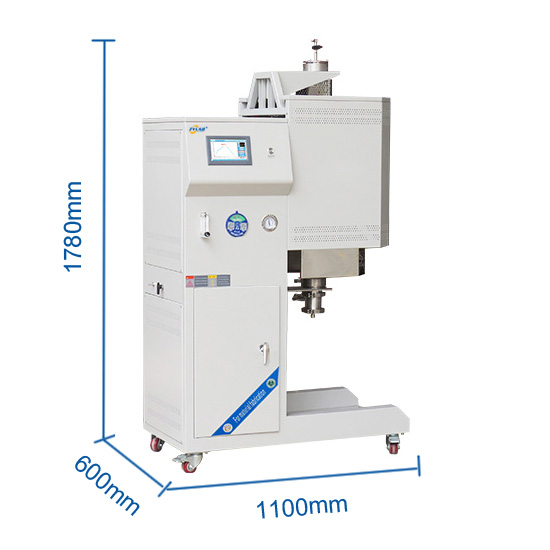

ZYLAB Vertical High Temperature Tube Furnace

Product Description:

The ZYLAB Vertical High Temperature Tube Furnace is a state-of-the-art laboratory furnace designed for precise thermal processing of various materials. Combining advanced manufacturing techniques with ergonomic and safety-conscious design, this vertical tube furnace ensures consistent results and reliable operation.

The furnace chamber is made of high-purity lightweight alumina fiber, providing excellent insulation and energy efficiency. The intelligent touch-screen interface allows for user-friendly operation, while the advanced PID self-learning fuzzy control model ensures precise temperature regulation with an accuracy of ±1°C. Extensive testing with a wide range of samples demonstrates that the furnace is suitable for nearly all types of material calcination, roasting, and thermal treatment. Standardized production ensures high reproducibility and consistency for laboratory and industrial applications.

Key Features:

-

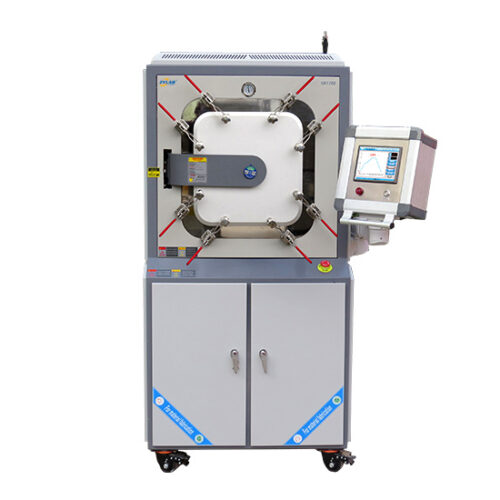

360° Uniform Heating – Ring-shaped heating elements distributed inside the chamber surround the tube completely, providing excellent temperature uniformity.

-

High-Purity Al₂O₃ Fiber Insulation – Superior refractory insulation reduces energy consumption and improves operational efficiency.

-

Double-Layer Air-Cooled Structure – The furnace body design helps lower the surface temperature for improved safety.

-

Intelligent PID Fuzzy Temperature Control – 7-inch touch-screen interface displays real-time time-temperature curves for precise control and easy monitoring.

-

Integrated Water-Cooled Flanges – Prevents flange overheating and protects sealing rings, ensuring reliable airtight performance.

-

Optional Quenching Function – Can be customized with a quenching module for advanced thermal processing needs.

Applications of Vertical High Temperature Tube Furnace:

-

Material Synthesis and Research – Perfect for synthesizing advanced ceramics, metals, alloys, and nanomaterials with controlled atmospheres.

-

Semiconductor and Electronic Materials – Suitable for annealing, sintering, and heat treatment of wafers, thin films, and electronic components.

-

Battery and Energy Materials – Ideal for research and development of lithium-ion, solid-state batteries, and other energy storage materials.

-

Chemical and Thermal Reactions – Supports controlled reactions in vacuum, inert, or reactive gas environments.

-

Powder Metallurgy and Advanced Composites – Used for sintering, calcination, and high-temperature treatments of powders and composites.

-

High-Temperature Testing – Enables precise thermal testing, stability studies, and material characterization at temperatures up to its maximum rated limit.

Technical Parameters:

| Model | LT1500-60 | LT1700-60 | LT1500-80 | LT1700-80 |

| Maximum Temperature | 1500°C | 1700°C | 1500°C | 1700°C |

| Continuous Operating Temperature | 300–1450°C | 300–1650°C | 300–1450°C | 300–1650°C |

| Heating Element | High-purity SiC rod | High-purity SiMo rod | High-purity SiC rod | High-purity SiMo rod |

| Power Supply | AC220V / 4.5KW | |||

| Temperature Accuracy | ±1°C | |||

| Thermocouple Type | Type S | Type B | Type S | Type B |

| Tube Diameter | 60 mm | 60 mm | 80 mm | 80 mm |

| Heating Zone Length | 80 mm | |||

| Furnace Chamber Effective Volume | Φ200 × 200 mm | |||

| Heating Rate | 1°C/h – 20°C/min | |||

| Furnace Dimensions (L×H×D) | 1100 × 1780 × 600 mm | |||

| Weight (kg) | 150 | 175 | 155 | 185 |

| Pressure Measurement & Monitoring |  |

Mechanical pressure gauge with airtight casing; corrosion and high-temperature resistant; protects internal components from environmental effects and debris | ||

| Gas Supply System |  |

Integrated rotameter for precise gas flow control; leak-tested before shipment | ||

| Control System |  |

|

||

| Optional Corrosive Gas Pre-Heater |  |

Made of 316L stainless steel; preheats various gases including weakly corrosive gases; maximum temperature 600°C | ||

| Warranty & Support | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. | |||

Advantages of ZYLAB Furnaces:

-

Flexible Customization – Designed to meet diverse laboratory demands

-

Widely Used in Research and Industry – Reliable performance in materials labs, universities, and production environments

-

Professional Support – Dedicated technical service and documentation

-

Efficient Logistics – Timely delivery and global shipment options

Click to See More Content

For More Options on Tube Furnaces

Click here [Tube Furnaces Collection]

For More Options on High Temperature Furnaces

Click here [High Temperature Furnaces Collection]