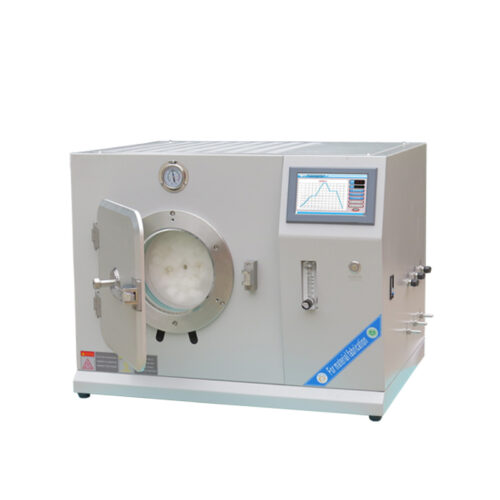

ZYLAB Vacuum Atmosphere Hybrid Box/Tube Furnace

Introduction:

The ZYLAB Vacuum Atmosphere Hybrid Box/Tube Furnace is an advanced high-temperature heat treatment system that integrates both box furnace and tube furnace functionalities. Designed for precise thermal processing under vacuum or controlled atmosphere conditions, this hybrid furnace is ideal for applications requiring high purity environments and uniform heating.

Equipped with a water-cooled flange system to reduce flange and seal temperatures, it ensures excellent vacuum integrity and system safety. This hybrid design makes it suitable for sintering, annealing, quenching, brazing, and crystal growth in scientific research and small-scale production.

Key Features & Advantages:

1. High-Precision Temperature Control

-

PID intelligent controller with multi-segment programmable ramp/soak curves.

-

Temperature uniformity of ±1–5°C depending on configuration.

-

Maximum temperature up to 1800°C (model-dependent).

-

Compatible with thermocouple or optional infrared pyrometry.

2. Vacuum & Atmosphere Control

-

Vacuum level down to 10⁻³ to 10⁻⁵ Pa (with optional molecular pump system).

-

Supports multiple gas atmospheres including inert (N₂, Ar), reducing (H₂), and custom gas mixtures.

-

Ideal for oxidation prevention, material reaction control, and purification processes.

3. Superior Heating Elements

-

High-quality Fe-Cr-Al alloy heating wires or optional MoSi₂ / SiC elements.

-

Long service life, stable performance across various temperature ranges.

4. Safety & Stability

-

Over-temperature protection, power/water failure alarms, and pressure relief valve.

-

Double-layer water-cooled chamber keeps the outer shell cool for safe operation.

5. Modular & Customizable Design

-

Customizable heating chamber sizes in both box and tube formats.

-

Optional upgrades: rapid cooling system, viewing window, material feeding or transfer mechanism.

6. Energy Efficient & Eco-Friendly

-

Multi-layer alumina fiber insulation minimizes thermal loss.

-

Energy-saving structure with low heat dissipation.

Technical specifications of Hybrid Box/Tube Furnace:

| Model | VAH1200-80 | |

| Power Supply | AC 220V, 50Hz | |

| Rated Power | 3.0 kW | |

| Temperature Accuracy | ±1°C | |

| Heating Element | Alloy resistance wire | |

| Maximum Temperature (Tmax) | 1200°C | |

| Continuous Working Temperature | 1150°C | |

| Recommended Heating Rate | ≤10°C/min | |

| Tube Size | Quartz tube Ø80 × 320 mm | |

| Chamber Hot Zone Size | 150 mm (L) × 150 mm (H) × 180 mm (D) | |

| Overall Dimensions | 350 mm (L) × 800 mm (H) × 370 mm (D) | |

| Net Weight | Approx. 50 kg | |

| Control System |  |

Programmable sintering curves with dynamic display Multiple preset process profiles Scheduled operation for unattended sintering Real-time display and data logging of power, voltage, etc. Data export for paperless records Remote control and monitoring support Automatic temperature correction throughout the sintering process |

| Equipment Details |  |

Furnace Chamber Interior |

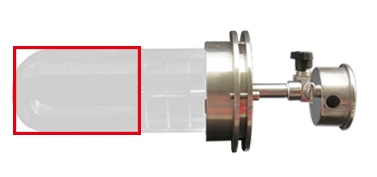

| Vacuum Reaction Chamber |  |

Quartz tube |

| Warranty & Support | 18 months(not including consumable parts, such as heating elements, thermocouple), lifetime support. | |

Applications:

-

Advanced material sintering

-

Metal and ceramic annealing

-

Crystal growth under inert or reducing gas

-

Powder metallurgy and brazing

-

Thermal treatment in research institutes and R&D labs

-

Surface treatment in semiconductor and photovoltaic industries

For More Content

Please read our blog: A Comprehensive Guide to Box Furnaces

For More Options on Box Furnaces

Please visit our website [Box Furnaces]

For More Options on High Temperature Furnaces

Please visit our website [High Temperature Furnaces Collection]