ZYLAB Split-Type Hydraulic Pellet Press

Introduction:

The ZYLAB 100 Ton Split-Type Automatic Hydraulic Pellet Press is a high-performance laboratory press specifically engineered for large-force powder compaction and pelletizing applications. With a fully automatic control system, real-time pressure monitoring, and a split-type design, it is ideal for XRF/XRD sample preparation, ceramic materials, battery powders, and other research applications requiring ultra-high pressure.

The separated controller ensures operational safety and minimizes electromagnetic interference, while the integrated safety shield enhances operator protection during high-pressure processing.

Main Features of Split-Type Hydraulic Pellet Press :

1. 100 Ton High Pressure Capability

-

Supports a maximum pressure of 100 tons (≈980 kN)

-

Suitable for large-size or high-density powder pellets

2. Split-Type Design

-

Main press unit and control system are physically separated

-

Enhances operational safety, heat resistance, and system stability

3. Full Automation

-

Automated pressurizing, holding, pressure compensation, and release

-

SAVTA intelligent system supports 5-stage (optional 15-stage) pressure programming

4. Real-Time Pressure Display

-

Converts hydraulic pressure to actual sample pressure

-

Overpressure alert and automatic protection included

5. 7-Inch Touchscreen Interface

-

Bilingual UI (Chinese/English)

-

Intuitive operation with precise parameter control

6. Advanced Safety Protection

-

Equipped with 10 mm alumina panels and 6 mm acrylic safety shield

-

Built-in limit switch, overload protection, and emergency stop

7. Data Logging & Export

-

Stores up to 10,000 operational records

-

Supports USB export for easy tracking and documentation

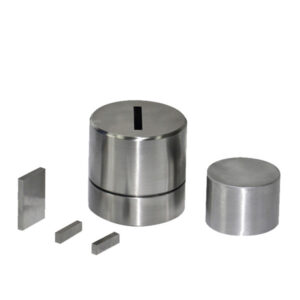

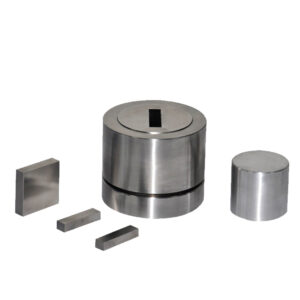

8. Custom Die Sets Available

-

Compatible with standard, special-shaped, tungsten carbide, XRF/XRD-specific, or electrically heated die sets

-

Contact us for custom solutions tailored to your application

Applications:

-

Laboratory powder pressing and pellet formation

-

XRF/XRD sample preparation

-

Material science, battery R&D, ceramics, metal powders

-

Research institutions, universities, and industrial labs

Specifications:

| Model | AP-65 | AP-100 | AP-150 | AP-200 |

| Pressure Range | 0.5-65T | 1-100T | 3-150T | 1-200T |

| Cylinder Diameter | 165mm | 200mm | 250mm | 290mm |

| Cylinder Stroke | ≤50mm | ≤50mm | ≤50mm | ≤50mm |

| Power Supply | 220V(50Hz/60Hz)/Customized 110V | |||

| Power Consumption | 800W | 1500W | 1500W | 1500W |

| Usable Space | 220x200x220mm | 260x260x230mm | 300x300x260mm | 350x350x260mm |

| Main Unit Dimensions | 330x400x725mm | 380x520x735mm | 420x600x925mm | 480x650x935mm |

| Main Unit Weight | 285Kg | 451Kg | 552Kg | 703Kg |

| Control Box Dimensions | 260x400x400mm | 300x480x480mm | 300x480x480mm | 300x480x480mm |

| Control Box Weight | 66Kg | 85Kg | 85Kg | 85Kg |

Why Choose ZYLAB Split-Type Hydraulic Pellet Press?

-

Precise control, safe design, and reliable automation

-

Trusted by university labs, R&D centers, and material testing facilities

-

Engineered for long-term use with high structural integrity and software flexibility

Matching Die Set:

If you require other special-shaped die sets, or specific types such as tungsten carbide dies, XRF-dedicated molds, or electrically heated die sets, please contact our customer service team immediately. Our technical engineers will assist you in evaluating feasibility and providing customized solutions tailored to your application needs.

For More Content

Please read our blog: Laboratory Powder Sample Forming Tools | Pellet Pressing Dies and Press

For More Options on Lab Press

Please visit our website [Lab Press & Rollers]

For More Options on Powder Material Preparation

Please visit our website [Powder Material Preparation Solution]